Products

Product Line

TM5

TM12/14

Selection

Product Line

OMRON TM Collaborative Robots

OMRON’s full line of collaborative robots includes a number of models to customize the right reach and payload for applications.

TM5

Collaborative Robots TM5

Collaborative robot for assembly, packaging, inspection and logistics

- Designed to promote a safe and harmonious workplace between humans and machines.

- Easy-to-use graphical programming environment for quick startup and operation.

- Built-in vision-based robot control enables visual servoing, inspection, and measurement operations.

- TMvision and landmark allows truly flexible, fast changeover.

- Pl ug & Pl ay ecosystem provides the tools and versatility for many manufacturing needs.

- Capability to integrate with mobile robots enables fully autonomous machine tending and logistics handling applications.

Specifications

I/O PortsControl BoxDigital In: 16

Digital Out: 16

Analog In: 2

Analog Out: 1

| TM5 | |||||||

| Product Name | TM5-700 | TM5M-700 | TM5M-700 SEMI | TM5-900 | TM5M-900 | TM5M-900 SEMI | |

| Part Number | RT6-000700X | RT6-010700X | RT6-010701X | RT6-000900X | RT6-0109000 | RT6-0109010 | |

| Weight (kg) | 22.1 | 22.6 | |||||

| Controller Weight (kg) | 13.5 | 14.5 | 14.5 | 13.5 | 14.5 | 14.5 | |

| Max Payload (kg) | 6 | 4 | |||||

| Reach (mm) | 700 | 900 | |||||

| Mounting | Wall, Table, Ceiling | ||||||

| Typical Speed (m/s) | 1.1 | 1.4 | |||||

| Joint Range | Joint 1 | ±270° | |||||

| Joint 2, 4, 5 | ±180° | ||||||

| Joint 3 | ±155° | ||||||

| Joint 6 | ±270 | ||||||

| Joint Speeds | Joint 1, 2, 3 | 180°/s | |||||

| Joint 4, 5, 6 | 225°/s | ||||||

| Repeatability (mm) | ±0.05 | ||||||

| IP | IP54 (robot arm), IP32 (control box), IP40 (robot stick) | ||||||

| Cleanroom Class | ISO Class 5 | ||||||

| Operating Temperature (°C) | 0 to 50 | ||||||

| Power Supply | 100-240 VAC,50- 60 Hz | 22-60 VDC | 22-60 VDC | 100-240 VAC, 50- 60 Hz | 22-60 VDC | 22-60 VDC | |

| Robot Arm Cable Length | 3m/12m | 1.5m | 1.5m | 3m/12m | 1.5m | 1.5m | |

| Tool | Digital In: 4 Digital Out: 4 Analog In: 1 Analog Out: 0 | ||||||

| I/O Interface | 3 X COM, 1 X HDMI, 3 X LAN, 4 X USB2.0, 2 X USB3.0 | ||||||

| Communication | RS232, Ethernet (master), Modbus TCP/RTU (master & slave) | ||||||

| Integrated Camera | 5M pixels, color | 5M pixels, color | 5M pixels, color | 5M pixels, color | 5M pixels, color | 5M pixels, color | |

| I/O Power Supply | 24V 1.5A (control box and tool) | ||||||

| Programming Environment | TMflow, flowchart based | ||||||

| SEMI S2 Certified* | No | No | Yes | No | No | Yes | |

* SEMI safety SEMI safety guidelines are issued by an industry association with the same name: SEMI (Semiconductor Equipment and Materials International), which is the central global network of manufacturers of micro- and nano-electronics industries.

* SEMI S2 is the most well-known standard in semiconductor manufacturing equipment for Environmental, Health, and Safety (EHS).

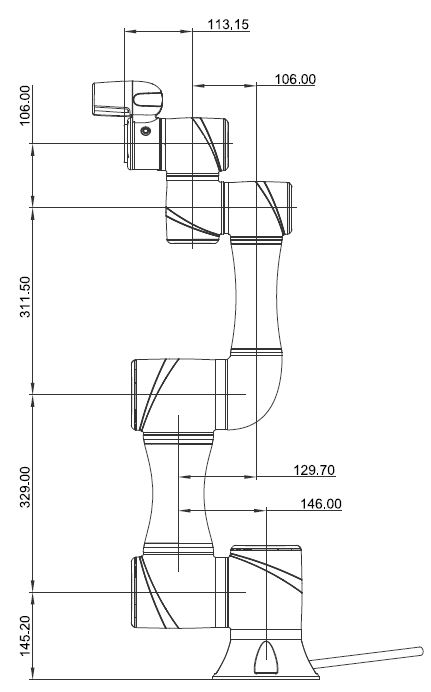

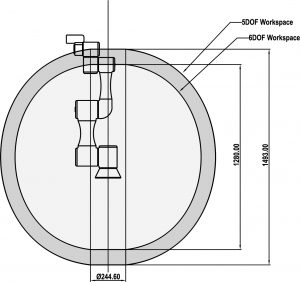

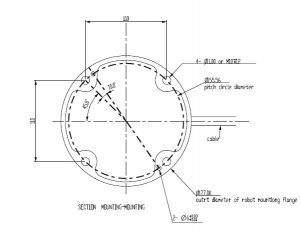

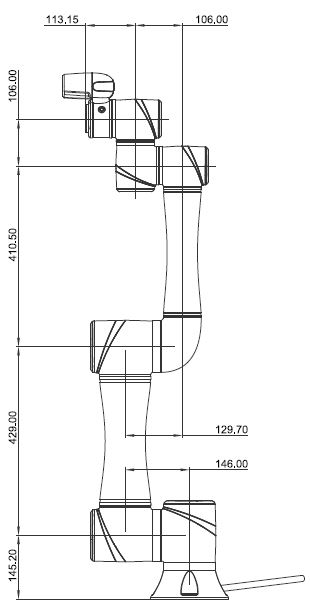

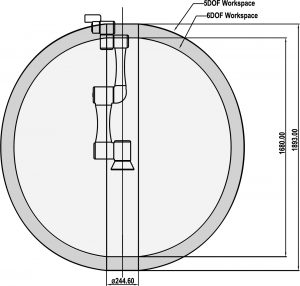

Dimensions

TM5 – 700

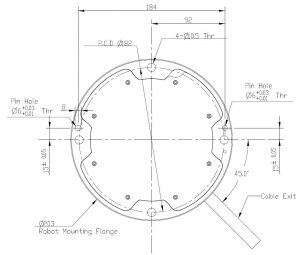

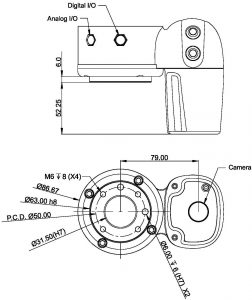

Footprint

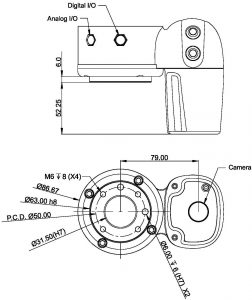

Flange

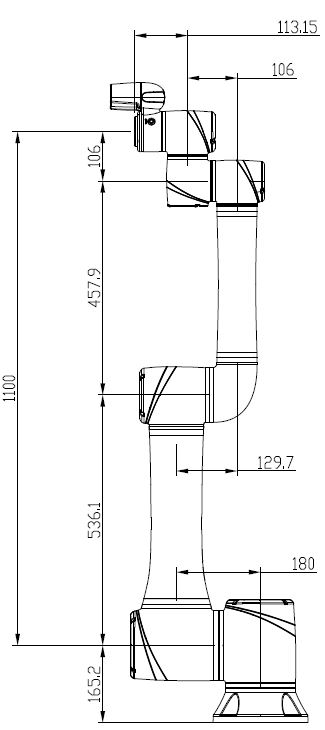

TM5 – 900

Control Box

TM12/14

Collaborative Robots TM12/14

Collaborative robot for assembly, packaging, inspection and logistics

- Designed to promote a safe and harmonious workplace between humans and machines.

- Easy-to-use graphical programming environment for quick startup and operation.

- Built-in vision-based robot control enables visual servoing, inspection, and measurement operations.

- TMvision and landmark allows truly flexible, fast changeover.

- Plug & Play ecosystem provides the tools and versatility for many manufacturing needs.

- Capability to integrate with mobile robots enables fully autonomous machine tending and logistics handling applications.

Specifications

| TM12 | TM14 | ||||||

| Product Name | TM12 | TM12M | TM12M SEMIM | TM14 | TM14M | TM14M SEMI | |

| Part Number | RT6-100130X | RT6-110130X | RT6-110131X | RT6-200110X | RT6-210110X | RT6-210111X | |

| Weight (kg) | 33.3 | 32.6 | |||||

| Controller Weight (kg) | 13.8 | 14.5 | 14.5 | 13.8 | 14.5 | 14.5 | |

| Max Payload (kg) | 12 | 14 | |||||

| Reach (mm) | 1300 | 1100 | |||||

| Mounting | Wall, Table, Ceiling | ||||||

| Typical Speed (m/s) | 1.3 | 1.1 | |||||

| Joint Range | Joint 1 | ±270° | |||||

| Joint 2, 4, 5 | ±180° | ||||||

| Joint 3 | ±166° | ||||||

| Joint 6 | ±270 | ||||||

| Joint Speeds | Joint 1, 2 | 120°/s | |||||

| Joint 3 | 180°/s | ||||||

| Joint 4, 5 | 180°/s | 150°/s | |||||

| Joint 6 | 180°/s | ||||||

| Repeatability (mm) | ±0.01 | ||||||

| IP | IP54 (robot arm), IP32 (control box), IP40 (robot stick) | ||||||

| Cleanroom Class | ISO Class 5 | ||||||

| Operating Temperature (°C) | 0 to 50 | ||||||

| Power Supply | 100-240 VAC, 50- 60 Hz | 22-60 VDC | 22-60 VDC | 100-240 VAC, 50- 60 Hz | 22-60 VDC | 22-60 VDC | |

| Robot Arm Cable Length | 3m/12m | 1.5m | 1.5m | 3m/12m | 1.5m | 1.5m | |

| I/O Ports | Control Box | Digital In: 16 Digital Out: 16 Analog In: 2 Analog Out: 1 | |||||

| Tool | Digital In: 4 Digital Out: 4 Analog In: 1 Analog Out: 0 | ||||||

| I/O Interface | 3 X COM, 1 X HDMI, 3 X LAN, 4 X USB2.0, 2 X USB3.0 | ||||||

| Communication | RS232, Ethernet(master), Modbus TCP/RTU (master & slave) | ||||||

| Integrated Camera | 5M pixels, color | 5M pixels, color | 5M pixels, color | 5M pixels, color | 5M pixels, color | 5M pixels, color | |

| I/O Power Supply | 24V 1.5A (control box and tool) | ||||||

| Programming Environment | TMflow, flowchart based | ||||||

| SEMI S2 Certified* | No | No | Yes | No | No | Yes | |

* SEMI safety SEMI safety guidelines are issued by an industry association with the same name: SEMI (Semiconductor Equipment and Materials International), which is the central global network of manufacturers of micro- and nano-electronics industries. SEMI S2 is the most well-known standard in semiconductor manufacturing equipment for Environmental, Health, and Safety (EHS).

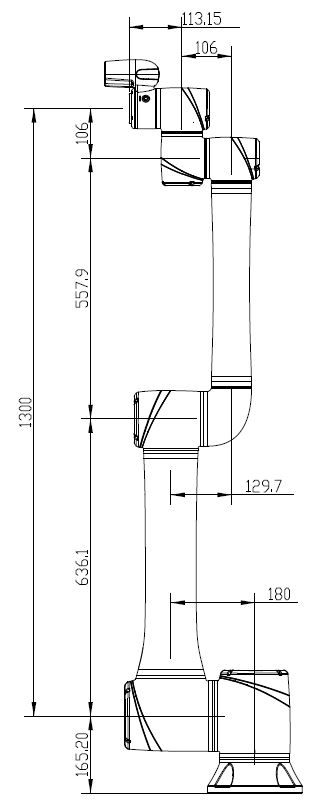

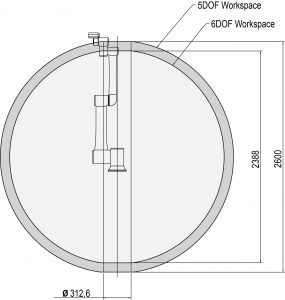

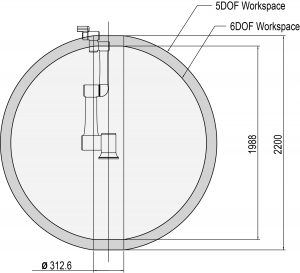

Dimensions

TM12

Footprint

Flange

TM14

Control Box

Selection

Software Selection

TMflow comes pre-installed in each robot controller. Customers can also download client version for free from OMRON websites, to run on customer laptops or tablets (Windows Surface only). If the customer needs extra vision capability, there are 3 add-on licenses available for TMFlow:

|

PRODUCT NUMBER |

LICENSE |

NOTES |

|

RT6-S100000 |

Identify & Measure |

Refer to Built-in Vision section for functionality. |

|

RT6-S100002 |

External Vision |

Required when external Basler cameras are used. Max of 2 external cameras allowed on 1 robot. |

|

RT6-S100003 |

OCR |

Refer to Built-in Vision section for functionality. |

If offline programming is needed, we provide TMflow Editor. Users can program all flowcharts and import to TMflow for next steps (e.g., record positions, teach vision jobs). There is 1 add-on license available to TMflow editor:

|

PN |

License |

Remarks |

|

RT6-S200001 |

TMflow Editor |

Offline flow creation and editing tool; no simulation. |

|

RT6-S100005 |

TMflow Editor – Offline AOI |

Add-on to TMflow Editor only; enables TMflow Editor to open an exported project form TMflow that includes AOI vision and offline edit. |