Back to case studies

Seals Finished in 9.5 Seconds at Trelleborg

Cycle time cut by 80% with robotics automation

Trelleborg Livorno, a leader in engineered polymer solutions, faced mounting pressure to deliver high-precision polyurethane seals for the wind energy market—faster and more flexibly than ever before. Traditional finishing methods limited throughput and made it difficult to respond quickly to changing customer demands.

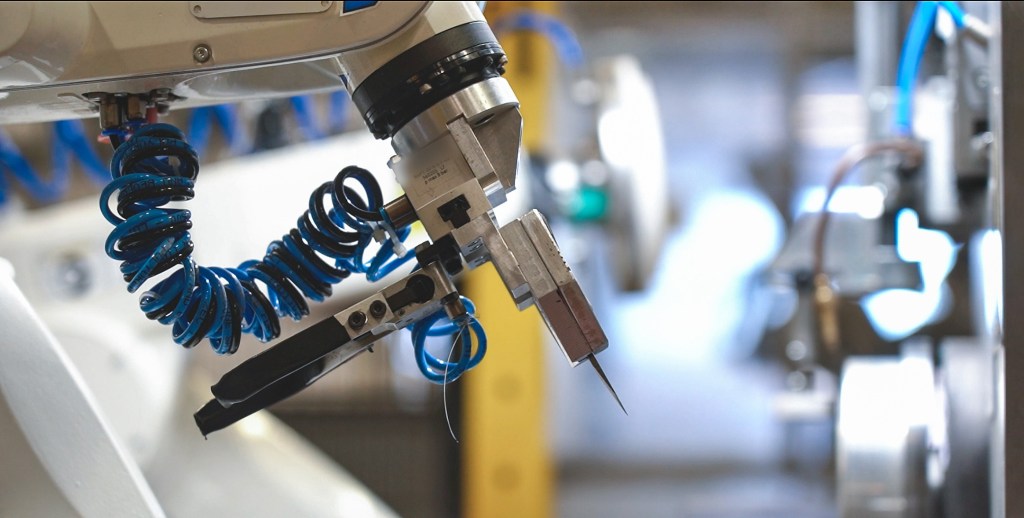

To overcome these challenges, Trelleborg introduced a seal finishing automation system powered by OMRON’s Robotics Integrated Controller. Two synchronized OMRON Viper 650 robots now manage pick-and-place and precision finishing operations, all seamlessly integrated with the machine’s logic, safety, and user interface. Operators can switch between product recipes in seconds, enabling rapid adaptation to new orders and custom requirements.

This advanced seal finishing automation has reduced cycle times from 17 seconds to just 9.5 seconds per part—an 80% improvement. Trelleborg now benefits from higher productivity, greater flexibility, and faster response to market needs, setting a new standard for quality and efficiency in industrial manufacturing.

Watch Trelleborg’s story:

Download in: Italian | German | Spanish | Polish | Turkish

“The new cell meets Trelleborg’s need to improve gasket stock procurement across Europe, Asia, and America, supporting customers even during sudden demand spikes. We expect a two-year ROI—a 30% improvement over previous solutions.” — Leonardo Ceccarini, Operations Manager, Trelleborg Livorno

Results at a glance:

- Cycle times reduced by 80%, down to just 9.5 seconds per seal

- 20% increase in overall productivity

- Seamless integration of robots, logic, motion, safety, and user interface

- Rapid recipe changes for flexible, on-demand production

- Faster ROI and improved supply chain responsiveness

Tailored automation for your operations

With our flexible and integrated solutions, manufacturers like Trelleborg can quickly adapt to changing demands while maintaining the highest standards of quality and efficiency. Interested in how robotics automation could transform your production process? Let’s design the right solution together.

Related insights

See all insights