Inspection

Automate quality control and testing in manufacturing with OMRON’s industrial robots.

Catching defects before they reach production

Stay ahead of quality and regulatory requirements with robots that automate inspection, environmental monitoring, and traceability. Integrated vision and sensors deliver dependable results and seamlessly adjust to changing inspection demands or product updates.

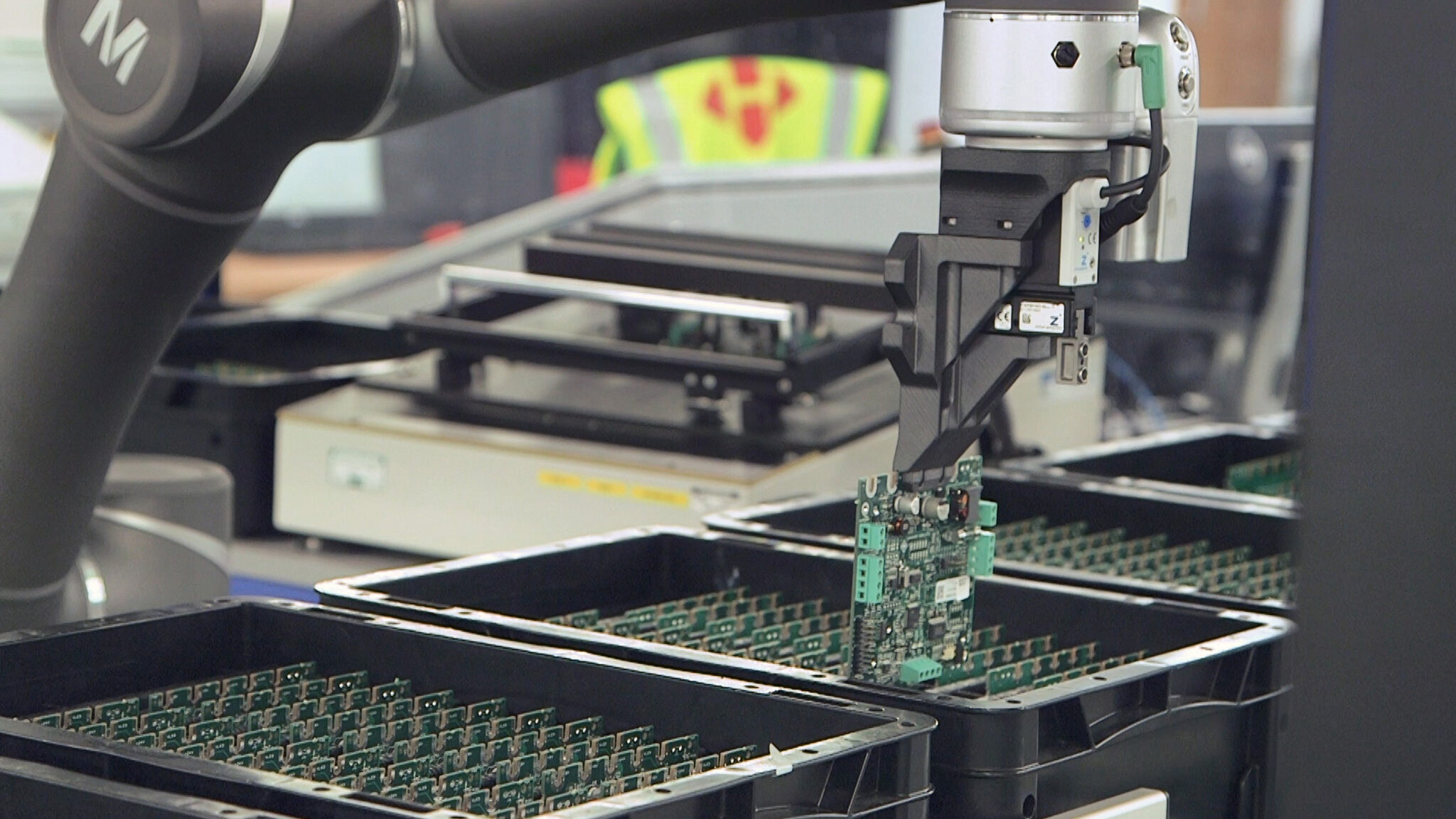

Automated quality inspection

OMRON TM S and TM Series collaborative robots automate repetitive inspection tasks including verifying automotive assemblies, inspecting electronic connectors, and checking food packaging for label errors. With integrated vision systems and intuitive programming, they ensure precise, repeatable results while safely working alongside people. Adapt quickly to new inspection needs and reduce downtime.

Lineside inspection & delivery

In inspection workflows, OMRON’s light- (LD-60/90, LD-250) and medium-duty AMRs (MD-650/900) autonomously transport parts between assembly and inspection stations, enabling just-in-time quality checks with less operator intervention. FLOW Core software manages fleet locations, traffic, and job assignments in real time, optimizing routes, preventing collisions, and integrating with MES/ERP systems to ensure accurate, efficient, and continuous inspection processes.

Environmental monitoring

Deploy AMRs with integrated environmental sensors to autonomously monitor temperature, humidity, and air quality across large facilities or hazardous zones. They collect and transmit real-time data, ensuring safety compliance and rapid detection of anomalies—without exposing personnel to risk.

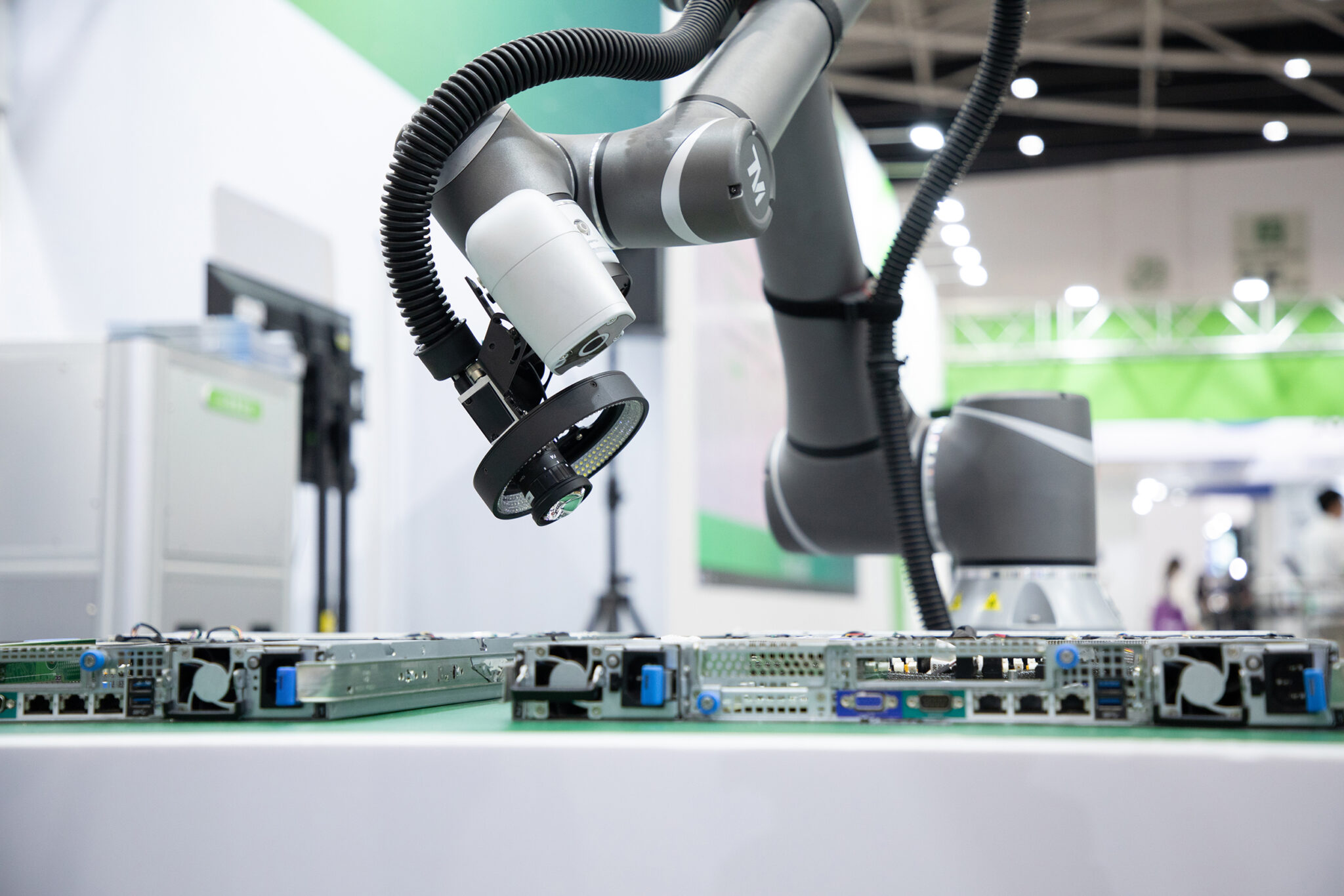

MoMas for flexible inspection

Mobile Manipulators (MoMas) with integrated vision and dexterous robotic arms pick and place parts, load machines, and perform detailed inspections—spotting assembly errors, surface defects, or label issues anywhere in your facility. Achieve greater operational flexibility and future-proof your inspection processes.

Start optimizing your production today

Have questions? Let’s chat!

Automate your applications

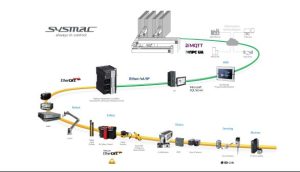

Streamline your workflows with Omron’s industrial automation solutions. Seamlessly program and synchronize robots, safety, and vision systems on one platform. Integrated simulation ensures easy deployment and efficient operations.

Motion

Servos minimize downtime and maintenance, while Industrial PCs ensure precise, reliable process control for automation.

Robotics

Program and integrate robots with the Robotics Integrated Controller—unifying automation and motion control for peak performance.

Control

Unify robotics and automation with the Robotics Integrated Controller for flexible scaling and precise control.

Vision

OMRON’s IPC Application Controller supports 8 cameras for high-speed, precise image processing.

Safety

Safety sensors ensure human-machine collaboration, while Remote I/O cuts downtime and costs with reliable, real-time performance.

RELATED PRODUCTS

Spot every detail with robotics

Enhance quality, safety, and productivity in your inspection process with advanced robotics tailored to your workflow. Achieve consistent, repeatable results and streamline operations through smart automation.

OMRON TM S Series

Next gen cobots with advanced vision for rapid, precise inspection and flexible deployment.

Viper

6-axis articulated robot for complex inspection and handling tasks.

OMRON TM Series

Versatile cobots for fast, reliable inspection and intuitive programming.

Autonomous Mobile Robots

AMRs for moving inspected goods and environmental monitoring.

Mobile Manipulators

Mobile manipulators for on-demand inspection and part transport.