Robotics for Packaging

Streamline packaging and pick-and-place with advanced robotics to boost quality and speed.

Right-sized solutions for every product run

Achieve fast, flexible, and precise packaging—from rapid picking and sorting to palletizing and traceable labeling. Our solutions handle frequent SKU changes, compact line layouts, and strict regulatory requirements, ensuring your packaging lines stay efficient, adaptable, and compliant.

High-speed pick & place

Maximize throughput and precision in primary and secondary packaging with robots engineered for speed, hygiene, and accuracy. Parallel models like iX3, Hornet, iX4, and Quattro excel at rapid sorting and placement—ideal for moving items directly from conveyors into trays, blisters, or cartons. i4L and i4H SCARA robots offer unmatched flexibility for tight spaces and high-speed cycles. Food-grade, cleanroom, and IP65 options ensure compliance with strict industry standards, while integrated vision systems deliver consistent, reliable results.

Flexible case packing & cartonizing

Automate box, case, and carton packing with collaborative, Viper, and i4 SCARA robots. These systems adapt quickly to different sizes, shapes, and packaging formats—including seasonal, promotional, or limited-edition runs. Vision-guided software enables rapid SKU changeovers, gentle handling of fragile products, and seamless stacking for efficient downstream logistics.

Sealing, closing & labeling

Guarantee every package is shelf- and compliance-ready with automated sealing, closing, and labeling. Parallel robots handle high-speed picking; SCARA models deliver exact sealing and labeling; TM S Series cobots offer flexible task switching for varying formats; and Viper articulated arms support complex, multi-axis operations. This ensures tamper-proof, accurately labeled products—critical for retail and regulatory standards.

End-of-line palletizing & logistics

Increase throughput and reduce manual labor with OMRON’s end-of-line automation. TM S Series collaborative robots and Viper 6-axis arms handle palletizing, depalletizing, and case sorting with speed and precision. AMRs (Autonomous Mobile Robots) transport finished goods across your facility, while fleet management software ensures safe, traceable, and reliable delivery—even during peak demand.

Integrated, end-to-end packaging

Transform your packaging line with Mobile Manipulator (MoMa) applications—combining collaborative and mobile robots for picking, inspection, sorting, packing, and facility-wide transport. Effortless integration and real-time adaptability mean you can respond instantly to new products, formats, and production demands, keeping your operations agile and future-ready.

Start optimizing your production today

Have questions? Let’s chat.

Automate your packaging line

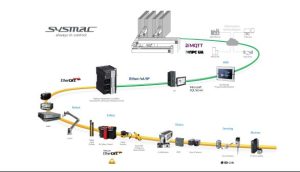

Streamline your packaging workflows with Omron’s industrial automation solutions. Easily program and sync robots, PLCs, safety devices, and vision systems on a single platform. Integrated simulation tools simplify deployment and troubleshooting for seamless operations.

Motion

Servos minimize downtime and maintenance, while Industrial PCs ensure precise, reliable process control for automation.

Robotics

Program and integrate robots with the Robotics Integrated Controller—unifying automation and motion control for peak performance.

Control

Unify robotics and automation with the Robotics Integrated Controller for flexible scaling and precise control.

Vision

OMRON’s IPC Application Controller supports 8 cameras for high-speed, precise image processing.

Safety

Safety sensors ensure human-machine collaboration, while Remote I/O cuts downtime and costs with reliable, real-time performance.

RELATED PRODUCTS

Robotic solutions built around your needs

Leverage advanced robotics to boost productivity, enhance safety, and ensure consistent quality on your packaging lines.

Viper

6-axis articulated robot for complex tasks up to 5 kg; high acceleration and flexible reach for demanding environments.

OMRON TM S Series

Collaborative robots with multiple payload and reach options; safe, precise, and easily redeployed for new tasks.

i4L

The compact SCARA robot manages up to 5 kg payloads with fast, precise cycles and space-saving design.

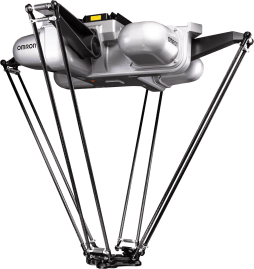

iX3 & Hornet

High-speed parallel robot, picks and places up to 8 kg with a 1130 mm reach for stable, efficient performance.

i4H

High-speed SCARA robot, handles up to 15 kg with ±0.015 mm precision, seamlessly integrating with Sysmac controls.

iX4 & Quattro

Four-arm parallel robot; delivers rapid, precise multi-picking for up to 15 kg, ideal for sanitary and high-demand settings.

OMRON TM Series

Flexible cobots with built-in vision; quick integration and fast setup for assembly, packing, and palletizing.

Autonomous Mobile Robots

Autonomous Mobile Robots streamline material flow and end-to-end production for efficient packaging automation.

Mobile Manipulators

Mobile Manipulators combine mobility and precision for inspecting, picking, and transporting tasks throughout your facility.

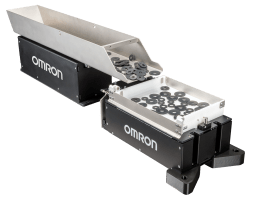

Industrial Part Feeders

Part feeders automate the delivery and orientation of bulk parts for consistent, high-speed feeding in packaging lines.