Unique & Emerging

Maximize productivity through flexible, safe and efficient robotics for emerging industries.

Turning complexity into consistency

Robotics empower manufacturers to reach new levels of productivity, quality, and safety. Whether in watchmaking, aerospace, hospitality, or personal care, automated solutions keep operations agile and results dependable—helping you lead, adapt, and grow as your demands evolve.

Automated excellence in Aerospace

Achieve new levels of precision and workflow flexibility. TM S Series cobots handle drilling, inspection, and assembly with advanced force control and vision. SCARA robots deliver fast, accurate placement for avionics and subassemblies, while Viper 6-axis robots automate complex assemblies and drilling. LD and OL-450S Autonomous Mobile Robots (AMRs) move parts and tools between stations, reducing manual transport and supporting lean production. Centralized fleet management software ensures reliable performance, real-time process visibility, and compliance with aerospace standards—helping you optimize efficiency and quality at every step.

UV-C disinfection and inspection

Ensure consistent hygiene and rapid turnaround in hotels, museums, gyms, and public spaces. UV-C mobile robots autonomously disinfect air and surfaces, covering every area safely. Automated air quality monitoring verifies sterilization, while LD series AMRs transport linens and supplies, supporting rapid turnaround and freeing staff for guest-focused tasks.

Accelerate clean energy production

Protect sensitive components and optimize material flow in renewable energy manufacturing. LD series AMRs with ESD-safe options ensure safe transport of solar cells and batteries. OL-450S AMRs automate and optimize roll cage movement for heavy loads, boosting efficiency and reducing manual handling. OMRON TM S Series cobots and Viper robots deliver consistent, high-throughput assembly of solar panels, battery modules, and power electronics, and perform tasks such as cell sorting, soldering, and quality inspection. Fleet management software enables real-time oversight and compliance for flexible, sustainable production.

Quality & compliance in home care

Deliver consistent quality and full traceability for every batch of home care products. OMRON TM S Series cobots automate ingredient loading, assembly, and end-of-line palletizing, using built-in vision systems for error-proofing and label verification. SCARA and parallel robots perform ultra-fast pick-and-place, sorting, and packaging, handling bottles, packets, and wipes with precision. AMRs streamline material transport and end-of-line logistics, improving efficiency and supporting compliance with FDA and ISO standards through automated record-keeping and audit trails.

Smarter plastics manufacturing

Cut labor costs and eliminate bottlenecks in plastics production. OMRON TM S Series cobots automate part unloading and assembly, improving cycle times and accuracy. Parallel robots handle high-speed pick-and-place of small molded components, while Viper robots tackle complex assembly and inspection. LD AMRs transfer heavy molds and finished products between machines and stations, reducing manual handling and keeping orders on schedule.

Transforming guest experiences

Enhance logistics and guest experience in hotels, casinos, malls, and museums. AMRs automate deliveries, facility services, and guest assistance, navigating busy environments safely and reliably. UV-C robots provide autonomous disinfection for public safety. Automation frees staff for high-value, guest-facing roles and enables safe, contactless service—boosting efficiency and scalability.

Safe & efficient glass handling

Ensure precise handling and safe transport of heavy, fragile glass materials. OMRON TM S Series cobots automate machine tending and assembly for payloads up to 25 kg, using vision for defect detection. AMRs (LD, MD, HD) smoothly move glass panels and finished goods across facilities, while fleet management software provides real-time reporting and operational control for consistent quality and reduced breakage.

Automation for paper and print

Meet high-volume demand and sustainability targets with robotics. OMRON TM S Series cobots handle inspection, material handling, packaging, and palletizing, adapting quickly to new formats. AMRs (LD-60/90, LD-250, OL-450S) move materials throughout your facility, boosting productivity, cutting waste, and supporting eco-friendly production.

High-quality appliance production

Manage complex assembly and inspection processes with efficiency. TM S Series cobots automate assembly, welding, and inspection of doors, panels, and internal components, using integrated vision for quality control. Viper and SCARA robots handle packaging and high-speed pick-and-place for shelves and trays. AMRs automate material and goods transport, enabling integrated, scalable production across the facility.

Start optimizing your production today

Have questions? Let’s chat!

Automate your operations

Maximize efficiency and agility with OMRON’s automation solution. Program and sync robots, vision systems, HMIs, PLCs, and safety devices for end-to-end control. Integrated simulation accelerates deployment and troubleshooting, ensuring rapid adaptation to new market demands.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

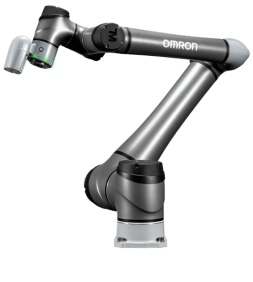

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable automated systems to interact with their physical environment, ensuring precise performance.

Safety

Safety sensors promote harmony between humans and machines, with Remote I/O cutting costs and downtime, ensuring reliable networks.

RELATED PRODUCTS

Unlock peak performance on your floor

Eliminate packaging bottlenecks, cut assembly downtime, and boost material handling output with robotics solutions for diverse manufacturing needs.

Industrial robots

Accelerate production by deploying industrial robots for assembly, material transport, and quality inspection.

Autonomous mobile robots

Streamline material flow with AMRs for flexible, efficient transport across diverse manufacturing environments.

Collaborative robots

Automate assembly, packaging, and inspection tasks safely and efficiently through human-robot collaboration.

Mobile Manipulators

Enable flexible automation with MoMas to streamline inspection, transport, and workflow improvement.

Related insights

Get more insights