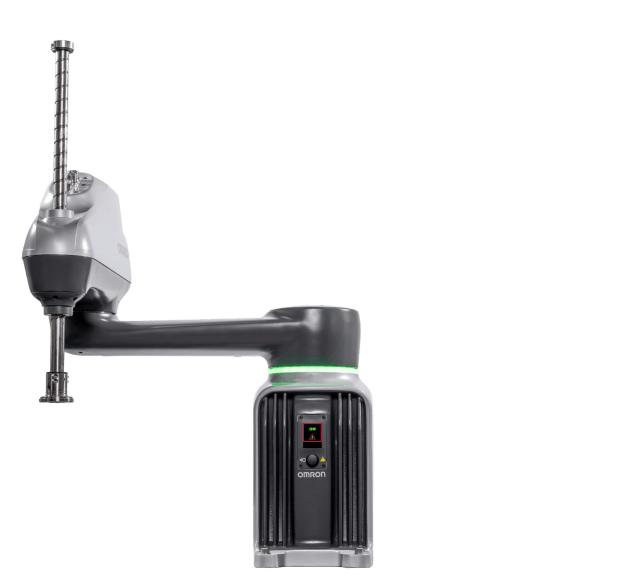

i4H

Automate repetitive tasks with the i4H SCARA robot—up to 15 kg payloads with 650-, 750-, or 850-mm reach options. Choose IP65, ESD, cleanroom, or food grade models for specialized environments. Integrated EtherCAT or Ethernet connectivity enables seamless connection to OMRON Sysmac PLCs, part feeders, and unified control with ACE or Sysmac for efficient automation.

i4-650H

|

Maximum reach |

650 mm |

|

Maximum payload |

15 kg |

|

Cycle times (at 2 kg) |

032-0.45s |

|

Number of axes |

4 |

|

Connectivity |

EtherCAT®, Ethernet, PROFINET |

|

Programming environment |

Sysmac Studio and ACE |

i4-750H

|

Maximum reach |

750 mm |

|

Maximum payload |

15 kg |

|

Cycle times (at 2 kg) |

0.31-0.46 |

|

Number of axes |

4 |

|

Connectivity |

EtherCAT®, Ethernet, PROFINET |

|

Programming environment |

Sysmac Studio and ACE |

i4-850H

|

Maximum reach |

850 mm |

|

Maximum payload |

15 kg |

|

Cycle times (at 2 kg) |

0.31–0.50 s |

|

Number of axes |

4 |

|

Connectivity |

EtherCAT®, Ethernet, PROFINET |

|

Programming environment |

Sysmac Studio and ACE |

Gallery

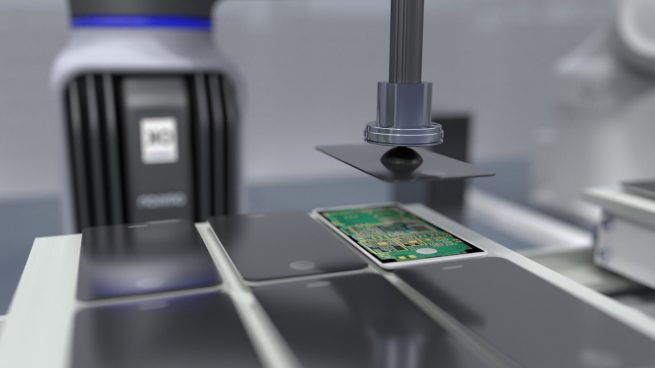

APPLICATIONS

Tailored solutions to meet your application’s demands

Discover how OMRON Robotics delivers advanced robotic solutions to solve unique manufacturing challenges worldwide—providing precision, flexibility, and productivity to help manufacturers achieve their goals.

See all applications

SOFTWARE

Smarter production starts with ACE

Optimize workflows and create smarter, more agile production lines with OMRON’s ACE software. Unlock the full potential of your i4H robots and feeding systems for unmatched performance. Use intuitive wizards to program robots, vision, I/O, and part-feeding systems in a single project.

Explore ACE

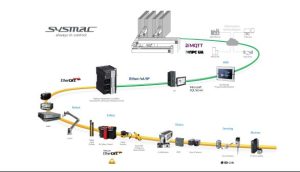

ROBOTICS CONTROLLER

Smarter systems for better results

Maximize output, minimize downtime, and adapt to changing demands with the Robotics Integrated Controller—synchronizing i4H robots and automation for faster results, simplified maintenance, and greater productivity in a single platform.

Explore the solution

video

FEEDING SOLUTIONS

Precision part feeding to power your production

Accelerate part handling with precise feeding for pick-and-place, assembly, and packaging. 3-axis vibration technology prevents jams, while modular design and ACE software enable rapid deployment and flexible integration across diverse applications.

Download brochure

iPF-240

Handles small parts (5-40mm) like screws, washers, and electronics with a compact design that ensures precision in tight spaces.

iPF-380

Ideal for medium parts (15-60mm) like fasteners and joints, ensuring precise orientation and smooth, reliable operations.

iPF-530

Designed for large parts (30-150mm) like housings and bearings, this heavy-duty feeder ensures durability with anti-roll surfaces.

Automate your applications

Maximize production efficiency with Omron’s Automation solutions—easily program and sync robots, vision systems, and safety devices on one platform. Integrated simulation accelerates deployment and troubleshooting for seamless operations.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

Robotics

A wide range of industrial robots, easily programmed with Sysmac Studio for seamless integration, control, and enhanced performance.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON manufactures cameras and vision sensors that enable our automated systems to seamlessly interact with their physical environment.

Safety

Safety sensors promote harmony between humans and machines, with Remote I/O cutting costs and downtime, ensuring reliable networks.

Start optimizing your production today

Have questions? Let’s chat.

RESOURCES

Your i4H resource hub

Find extensive resources and technical documentation in our support section to optimize the performance of your i4H robot.

Access i4H resources

SERVICE

Global service and support network

OMRON Robotics provides worldwide support, training, and safety services to ensure maximum robot uptime, enhanced efficiency, and top performance.

Learn more