OMRON TM20S

The TM20S is built for heavy‑duty palletizing, packaging, and machine tending—delivering stable motion, certified safety, and fast setup in compact cells. It helps manufacturers move faster with cleaner stacks, reliable part handling, and confident changeovers, powered by a lightweight arm, integrated vision, and an intuitive no‑code programming environment.

OMRON TM20S

|

Maximum payload |

20 kg |

|

Maximum reach |

1300 mm |

|

Repeatability |

± 0.05 mm |

|

Average speed |

1.1 m/s |

|

IP and cleanroom class |

IP65 for Robot Arm |

|

Programming environment |

TMflow, TMScript, TMCraft |

Gallery

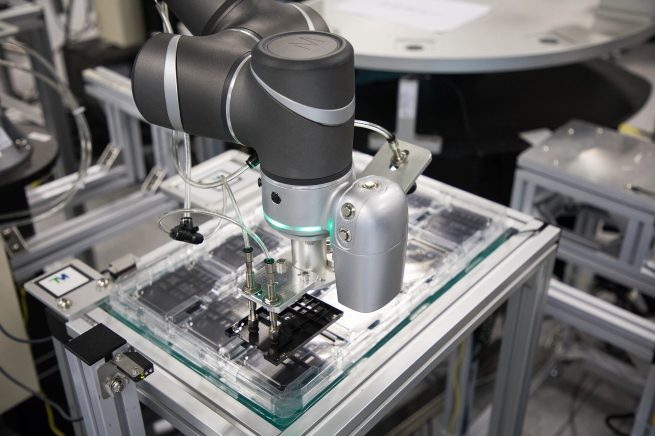

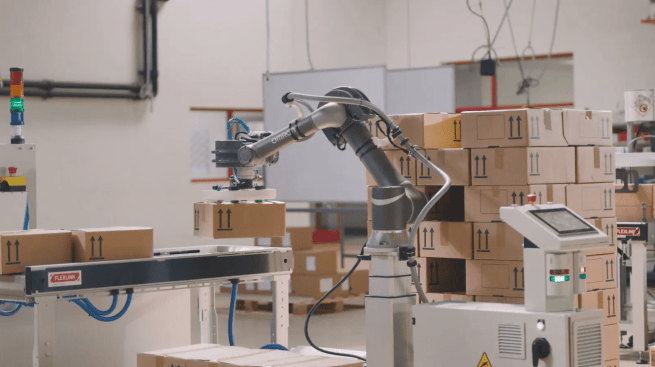

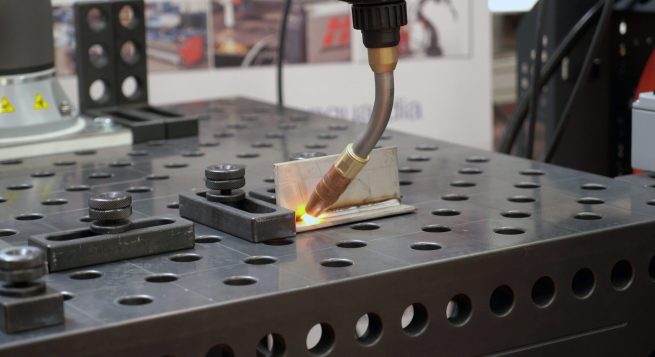

APPLICATIONS

Built for your most demanding applications

From end‑of‑line pallet stacks to box loading and repeatable CNC part handling, TM20S keeps placement clean, cycles consistent, and changeovers quick—configured to your products, layouts, and evolving throughput goals.

See all applications

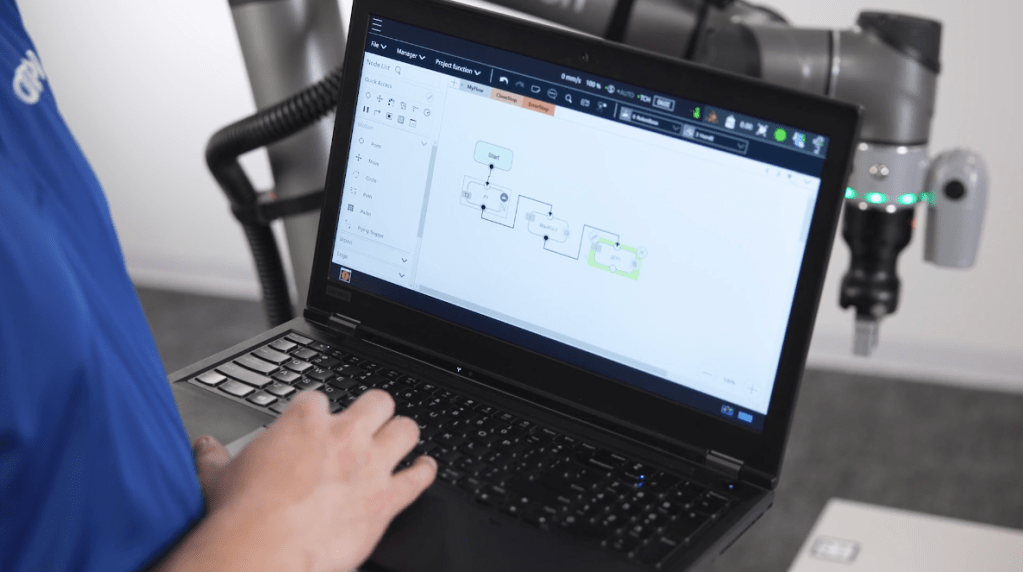

SOFTWARE

Power up performance with TMflow

TMflow software keeps the TM20S simple to program and easy to scale. Hand‑guide waypoints, build flows with visual blocks, or add scripts when logic is complex. Validate with TMSimulator offline, then deploy with integrated safety tooling and vision to cut setup time and reduce rework.

Learn more

ACCESSORIES

Smarter tools, better results

Pair TM20S with vacuum or mechanical grippers, Landmark positioning, and conveyor I/O kits to build compact cells that install quickly and keep cycles consistent. Built‑in vision handles part finding and inline inspection while protective covers and ESD‑safe tooling protect uptime across machine shops, SMT lines, and sterile packaging.

Download brochure

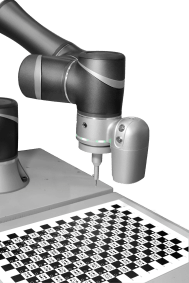

Landmark 2.0

Positioning tool for cobot reference to the environment, included with most models for precise setup.

TM screen with pen

Touchscreen teaching pendant for easy operation, compatible with TM S Series cobots, no extra wiring needed.

Robot stand

Portable stand for moving cobots between stations, ensuring stability and adaptability in dynamic setups.

Mobile workstation (MWS)

Mounts cobot securely, stores control box, and allows easy movement between work cells, boosting flexibility.

Calibration kit

Toolkit for precise tool center point (TCP) teaching and manual workspace calibration, critical for accurate vision tasks.

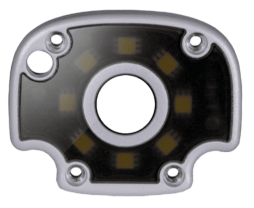

Polarizer light module

Reduces reflections on shiny surfaces, improving vision accuracy for TM S Series cobots.

SSD with cable

128 GB solid-state drive with SATA cable, recommended for external camera image logging, ensuring smooth data handling.

Air filter

Replenish or replace the air filter in your cobot’s electric control box to maintain peak performance and extend its lifespan.

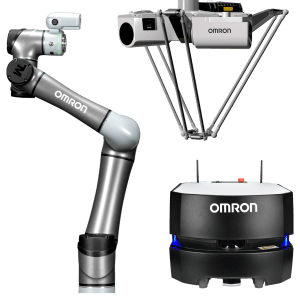

MANIPULATOR SOLUTION

Collaborative production starts with MoMa

Mobilize workcells with OMRON MD or HD AMRs. TM20S runs palletizing, packaging support, and machine tending at line‑side, shifting between stations to lift utilization and keep flow moving—typical moves include end‑of‑line pickup and drop‑off, mobile fixture loading, and cross‑cell transfers.

Learn more about MoMas

video

End-to-end automation

Connect TM20S cells with AMRs, vision, and safety into one smooth flow—from infeed to pallet. With standard software and quick changeovers, you avoid isolated cells and keep throughput up while quality and compliance stay tight.

Motion

Servos ensure efficient line movement, reducing downtime and maintenance for smoother, more reliable operations.

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units integrate with your production line, maximizing productivity while saving space with built-in systems.

Vision

Cameras and sensors adapt to your environment, enabling smooth, accurate, and high-quality automated processes.

Safety

Safety sensors ensure seamless human-machine collaboration, reducing risks and enhancing workplace safety.

Start optimizing your production today

Have questions? Let’s chat.

RESOURCES

Your go-to resource hub

Access TM20S manuals, TMflow releases, technical documentation, and safety certifications. Find setup guides, template flows, and best‑practice notes to move from testing to production quickly.

Get TM20S resources

SERVICE

Global service and support network

OMRON Robotics provides worldwide support and training to keep your robot fleet running at peak efficiency, ensuring optimal uptime and performance.

Learn More

Related insights

See all insights