Product

Parallel Robots

Achieve high-speed, precise pick-and-place with parallel robots—maximizing throughput and reliability.

Models

Models

iX3

The iX3 parallel robot excels at high-speed pick-and-place operations, handling payloads up to 8 kg with a tracking speed of 1.4 m/s and a reach of 1130 mm. Its multi-picking capability and reduced vibrations ensure efficient, stable, and cost-effective performance.

Maximum working diameter |

1130 mm |

Maximum payload |

8 kg |

Cycle times (at 2 kg) |

0.32 s |

View product details

Hornet

The Hornet robot manages high-speed pick-and-place operations with 8 kg payloads, 1.4 m/s tracking speed, and a 1130 mm reach. Its multi-picking support and reduced vibrations ensure efficient, optimal performance for demanding tasks.

Maximum working diameter |

1130 mm |

Maximum payload |

8 kg |

Cycle times (at 2 kg) |

0.32 s |

View product details

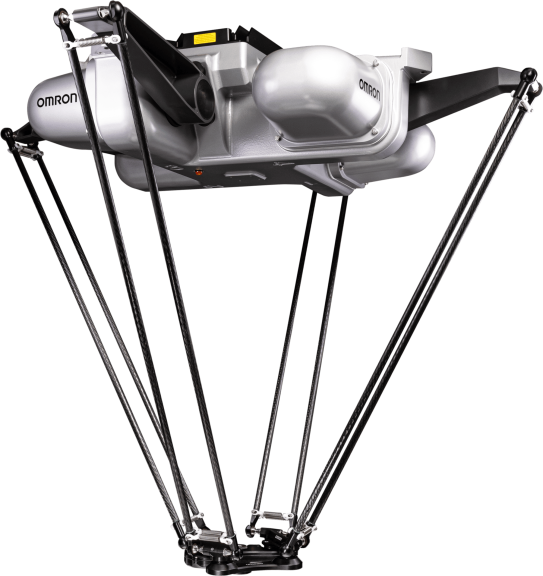

iX4

Featuring a patented 4-arm design, the iX4 robot handles payloads up to 15 kg with exceptional speed and precision. Its USDA-compliant performance ensures reliability and efficiency in high-demand, sanitary applications, such as food processing and pharmaceutical packaging.

Maximum working diameter |

1300 mm and 1600 mm |

Maximum payload |

15 kg |

Cycle times (at 2 kg) |

0.30-0.42 s |

View product details

Quattro

With a patented 4-arm design, the Quattro robot handles up to 15 kg payloads with speed, precise multi-picking, and USDA-compliant performance—ensuring reliability and efficiency in high-demand, sanitary applications.

Maximum working diameter |

1300 mm and 1600 mm |

Maximum payload |

15 kg |

Cycle times (at 2 kg) |

0.30-0.42 s |

View product details

Comparison

Product

Max. working diameter

Max. payload

Cycle times (at 2 kg payload)

Number of axes

Protection class options

Robot controller options

Mounting options

Programming environment

Connectivity

|

|

||||

|---|---|---|---|---|

|

Max. working diameter |

1130 mm |

1130 mm |

1300 mm (iX4-650) 1600 mm (iX4-800) |

1300 mm (Quattro 650) 1600 mm (Quattro 800) |

|

Max. payload |

8 kg (3-axis) 3 kg (4-axis) |

8 kg (3-axis) 3 kg (4-axis) |

15 kg (iX4-650) 10 kg (iX4-800) |

15 kg (Quattro 650) 10 kg (Quattro 800) |

|

Cycle times (at 2 kg payload) |

0.32-0.42 s |

0.32-0.42 s |

0.30–0.61 s (iX4-650) 0.33–0.62 s (iX4-800) |

0.30–0.61 s (Quattro 650) 0.33–0.62 s (Quattro 800) |

|

Number of axes |

3-axis 4-axis |

3-axis 4-axis |

4 |

4 |

|

Protection class options |

IP20 IP65 IP67 |

IP20 IP65 IP67 |

IP20 IP65 IP67 |

IP65 IP66 for 650HS |

|

Robot controller options |

OMRON NJ501-R (via EtherCAT®) |

SmartController EX NJ/NX/NY Series |

OMRON NJ501-R (via EtherCAT®) |

SmartController EX NJ/NX/NY Series |

|

Mounting options |

Inverted |

Inverted |

Inverted |

Inverted |

|

Programming environment |

Sysmac Studio |

ACE Software ePLC |

Sysmac Studio |

ACE Software ePLC |

|

Connectivity |

EtherCAT® via OMRON NJ501-R |

EtherCAT® Ethernet |

EtherCAT® via OMRON NJ501-R |

Ethernet |

APPLICATIONS

Custom solutions for industrial applications

Discover how OMRON Robotics develops tailored solutions to address manufacturing challenges—optimizing production, reducing downtime, and improving efficiency for customers worldwide.

See all applications

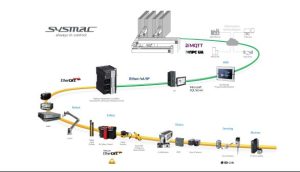

End-to-end automation

Boost productivity with OMRON’s complete automation platform. Manage robots, vision, motion, and safety on one system—and validate end-to-end in simulation for faster, more reliable deployment.

Motion

Servos reduce downtime and maintenance, while Industrial PCs ensure precise, reliable process control for automation.

Robotics

Program industrial robots easily with Sysmac Studio. SmartController EX ensures seamless integration and high performance.

Control

Compact control units save space and boost productivity. PLCs provide full process control for efficient automation systems.

Vision

OMRON cameras and sensors enable robots to interact seamlessly with their environment, ensuring precision and accuracy.

Safety

Safety sensors ensure human-machine harmony, while Remote I/O reduces costs and downtime with reliable network performance.

Start optimizing your production today

Have questions? We’re here to help.

SOFTWARE

Smarter production lines start with ACE

Set up and synchronize robots, conveyors, vision solutions, and motion control with OMRON ACE software for precise multi-pick, faster cycles, and consistent accuracy in high-speed packaging and sorting.

Learn more

SERVICE

Global support and service network

OMRON Robotics offers global support, training, and safety services to keep your parallel robots running at peak efficiency—ensuring maximum uptime and optimal performance.

Learn more

Related insights

See all insights