Back to case studies

Gruppo Romani Cuts Labeling Downtime by 70% with Automated Cobot Solution

From manual bottlenecks to rapid, flexible labeling with cobots

Gruppo Romani, a leading Italian ceramics manufacturer, needed to streamline its package labelling process to keep up with evolving production demands. The manual and mechanical labelling systems in use were slow to adapt to frequent format changes, especially when handling fragile, breakable products. This resulted in significant downtime and limited flexibility, impacting productivity and traceability.

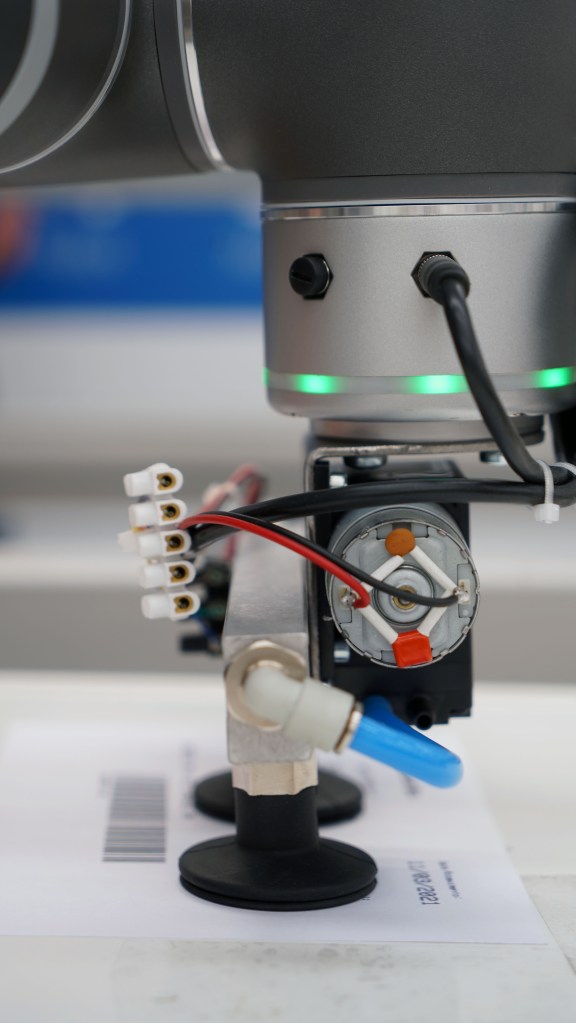

To solve this, Bluengineering developed a fully automated labeling solution using the OMRON TM5-900 collaborative robot. The TM5-900 cobot—with its integrated vision system and 700 mm reach—was deployed to handle label application on any of the four sides of outgoing packages. Its flexible programming allows operators to quickly teach the cobot new gripping, movement, and deposit points, enabling rapid adaptation to different package sizes and shapes. The system is managed centrally by an OMRON NX102 PLC, which connects seamlessly to the manufacturing execution system (MES) for real-time supervision and traceability. Barcode and QR code verification, package tracking, and label quality checks are all performed automatically by the integrated vision system.

This automated package labeling system has transformed Gruppo Romani’s operations—reducing downtime from format changes by up to 70%, freeing operators for higher-value tasks, and ensuring safe, efficient, and future-proof production.

Watch Gruppo Romani’s story:

Results at a glance:

- Up to 70% reduction in downtime for label format changes

- Flexible labeling on multiple package formats and sizes

- Automated barcode and QR code verification for full traceability

- Safe, collaborative operation alongside factory staff

Tailored automation for your operations

Every production line faces its own challenges, and finding the right balance between efficiency, flexibility, and reliability can make all the difference. Gruppo Romani’s journey shows how the right automation solution can empower teams, reduce downtime, and adapt to changing needs.

If you’re exploring ways to improve flexibility and efficiency in your own production processes, we’re here to share our experience and help you find the right robotics automation approach—tailored to your unique needs.

Related insights

See all insights