Back to case studies

Mackle Petfoods Packs 135 Pouches per Minute with Automated Precision

Solving labor intensity and placement errors with robotics and vision

Meeting the rising demand for single-serve, recyclable pet food packs meant Mackle Petfoods had to rethink its pouch-handling process. Manual operations were slow, error-prone and required constant attention to avoid misalignment and contamination.

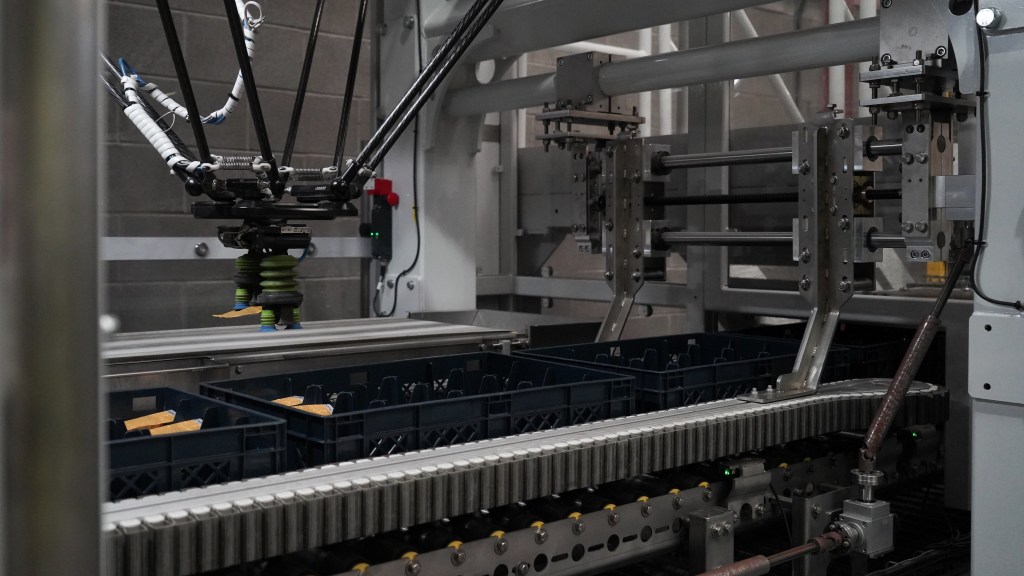

To address these challenges, Mackle teamed up with Clevertech and OMRON to automate critical steps in its new flexible pouch line. The automated packaging solution integrates iX4 parallel robots, OMRON FH vision systems, and PLC control to handle up to 135 pouches per minute—each placed with ±1 mm accuracy. Robots use custom 3D-printed grippers to manage highly flexible pouches, reliably inserting them into “smart” crates for efficient storage and multi-flavor carton packing.

Unlike manual handling, the automated system eliminates placement errors and the need for dedicated pick-and-place operators. Now, a single technician oversees the entire process. The system’s compact footprint frees up 30% of factory space, enabling future expansion and doubling output with minimal investment. OMRON’s vision cameras identify pouch orientation and graphics, even with moisture or reflections. Synchronized conveyor and robotic modules ensure every pouch is handled with care and precision, regardless of shape or print variation.

Switching to mono-material BOPP pouches and fully recyclable components puts Mackle ahead of upcoming EU sustainability regulations—reducing waste and supporting a circular economy model while future-proofing their packaging operations.

Watch Mackle Petfoods’ story:

Download in: Spanish | French | Italian | German | Polish

“We wanted to automate a completely manual process to boost efficiency, productivity, and to future-proof our operations. We’re already running 135 pouches per minute, and the system is designed to double that capacity.” — Gareth Rogers, Head of Engineering, Mackle Petfoods

Results at a glance:

- 50% productivity increase over manual methods

- Throughput of 135 pouches per minute, with scalable future capacity

- Zero placement errors thanks to ±1 mm robotic accuracy

- No dedicated operators required for pick-and-place tasks

- 30% reduction in line footprint

- Higher crate fill rates and improved packing efficiency

- Supports recyclable, mono-material packaging

Tailored automation for your production line

Mackle’s new pouch packing system shows how robotics, vision and control can solve complex handling challenges while delivering measurable improvements in speed, accuracy and sustainability. Interested in making your packaging process more efficient and future-ready? Let’s talk about how automation could work for you.