Back to case studies

TePe Boosts Output to 300 Packs per Minute—and ROI in 14 Months

Transforming oral care manufacturing with automation and smart inspection

TePe, a leader in oral hygiene products, faced a challenge familiar to many growing manufacturers: rising global demand was straining a manual production line that limited both speed and flexibility. To keep pace, TePe needed to boost throughput without sacrificing product quality or workplace safety.

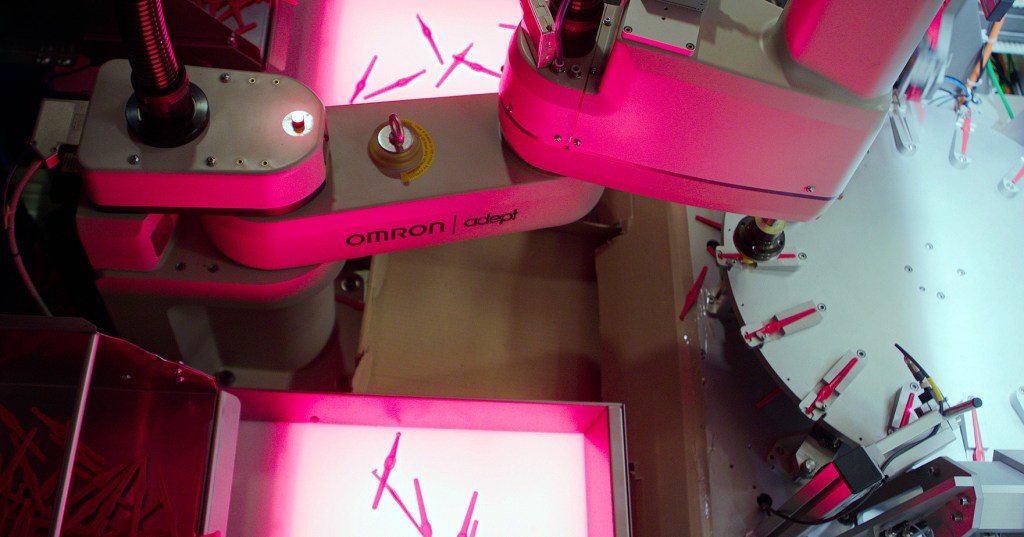

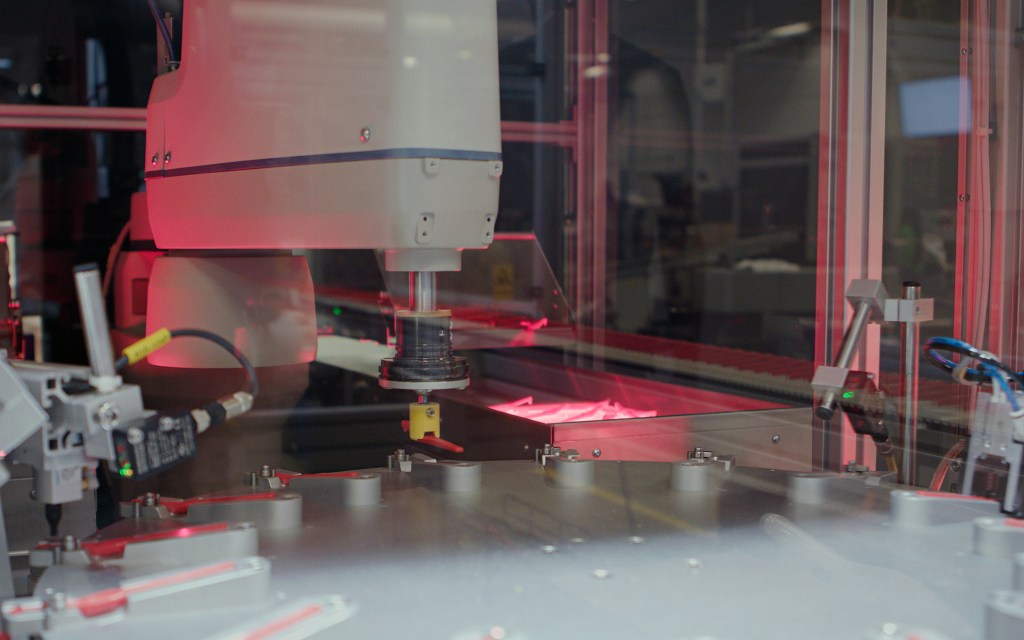

Partnering with OMRON and PMA AB, TePe implemented a high-speed automation line featuring five industrial robots, two OMRON LD-60 Autonomous Mobile Robots, and ten vision systems for automated quality inspection. This integrated solution replaced manual handling and enabled the line to reach 300 toothbrush packs per minute—a ninefold increase over the previous process.

Automated quality inspection now guarantees every product meets strict standards, while Autonomous Mobile Robots streamline logistics and reduce safety risks by replacing forklifts and conveyors. Customized packaging changes take just seconds, empowering TePe to respond instantly to customer needs. The result: TePe achieved full return on investment in just 14 months, with a flexible, future-proof system that adapts as requirements evolve.

Watch Tepe’s story:

Download in: Italian | German | Spanish | French | Turkish

“The mobile robots bring a huge improvement regarding safety. Driving forklifts pose a potential risk of accidents that we wish to remove, and at the same time we can remove conveyors that are often in the way. The mobile robots also make the production more flexible.” — Ronnie Sik, Technical Manager, TePe

Key results:

- 300 toothbrush packs per minute with automated quality inspection

- 9x increase in throughput

- ROI achieved in just 14 months

- Instant recipe changes for customization

- Eliminated forklifts and conveyors for improved safety

- Five industrial robots, ten vision systems, and two AMRs—all in one line

Tailored automation for high-mix, high-speed production

With OMRON’s automated packaging solutions, manufacturers like TePe can scale production, maintain strict quality standards, and respond instantly to customer demands. Our technology empowers you to boost productivity, ensure safety, and future-proof your operations.

If you’re facing similar challenges in medical manufacturing, let’s shape the future of your operations together—discover how automation and advanced quality inspection can deliver measurable results for your business.