Back to case studies

How Werfen Labels 1000 Vials Per Hour with Automation

Meeting the demands of modern clinical labs with precision automation

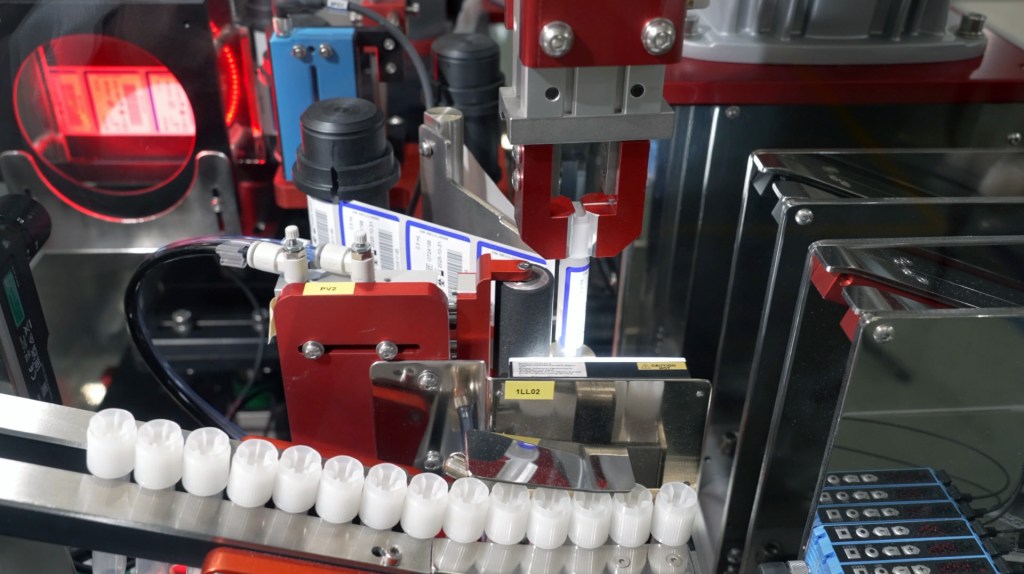

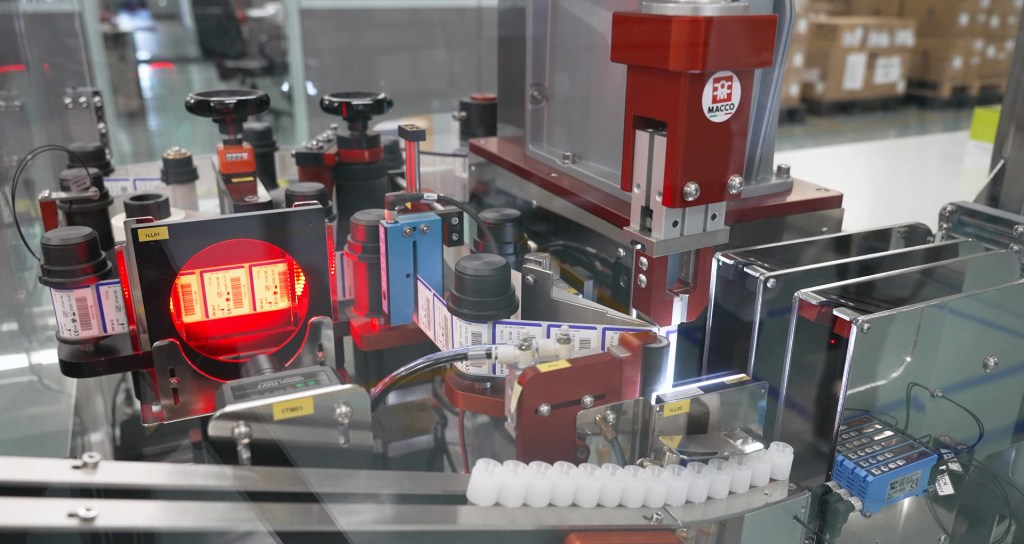

Werfen, a global leader in in-vitro diagnostics, faced a surge in demand for control and calibration materials—especially from toxicology labs that require sensitive reagents handled with the utmost care. Traditional labelling systems could not guarantee the vertical handling needed to preserve reagent quality, nor could they keep up with the required production speed. To solve these challenges, Werfen partnered with OMRON, MACCO, and Marini Pandolfi to implement an advanced automated vial labelling solution.

The result: a cutting-edge system powered by OMRON’s i4L SCARA robots and FHV7 smart vision cameras, designed to maintain vials upright throughout the entire filling and labelling process. This precise method protects reagent quality, ensures full traceability, and guarantees safe handling—while delivering up to 1000 labelled tubes per hour and reducing cycle times by 30%.

OMRON’s robotics and vision technology enable precise barcode and label placement, while real-time quality control automatically detects and rejects non-conforming tubes, minimizing waste and maximizing reliability. Virtual simulation technology allowed Werfen to predict system performance before installation, optimizing reliability and reducing implementation costs.

Watch Werfen’s story:

Download in: Italian | German | Spanish | French | Polish | Turkish

”The solution proposed by MACCO was a breakthrough for us because, with OMRON’s robotic and vision system, we can handle the product vertically and control its quality right to the end.” — Bruno Costantini, Plant Manager, Werfen

Results at a glance:

- Up to 1000 vials labelled per hour

- 30% reduction in cycle time compared to manual processes

- Enhanced quality control with smart vision systems

- Minimized waste through real-time rejection of non-conforming tubes

- Simulation-driven design improved reliability and cut implementation costs

Tailored automation for diagnostics manufacturing

With OMRON’s automated vial labelling solutions, manufacturers like Werfen can rapidly scale up production, maintain the highest standards of quality, and meet the strict requirements of the diagnostics industry. Our expertise in industrial automation empowers you to boost productivity, ensure safety, and future-proof your operations.

Ready to transform your production process? Contact us today to see how OMRON can design an automated solution tailored to your workflow.

Related insights

See all insights