Back to case studies

EasyArc Automated Welding Boosts Flexibility and Output at Guidetti Technology

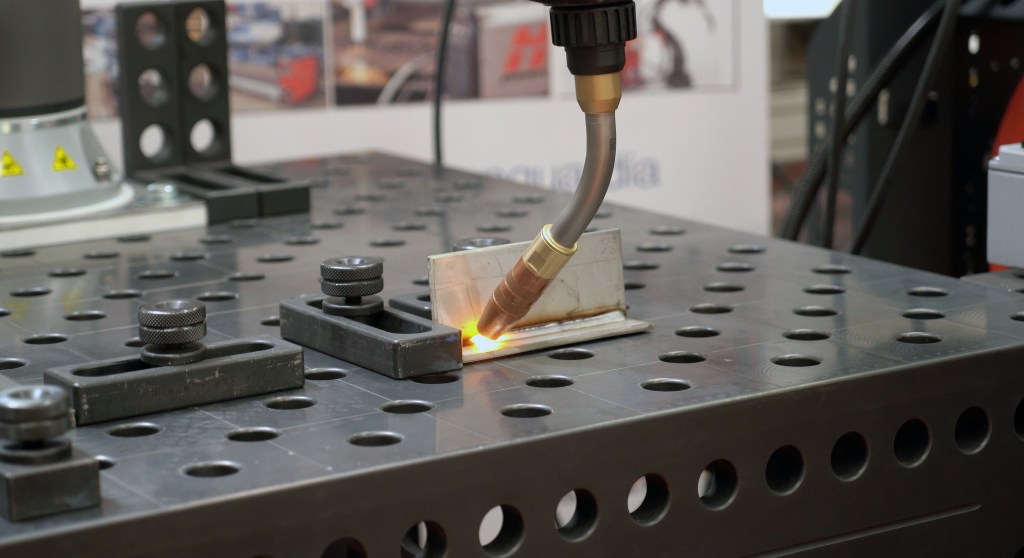

Streamlining small-batch metal fabrication with collaborative robots

Guidetti Technology SRL, a Modena-based specialist with 50 years of experience in welding systems, sought to address a key challenge in metalworking: repetitive welding tasks were limiting production flexibility and tying up skilled welders.

To solve this, Guidetti integrated OMRON TM12-X collaborative robots into its EasyArc automated welding solution. Designed for small batches across various types of metal carpentry, the solution pairs the cobot with OMRON’s intuitive NB7 operator panel, NXP2 PLC, and Fronius modular welding technology. This setup supports a wide range of welding processes, including MIG (Short/Spray, Pulsed, LSC, PMC, STEEL), Cold Metal Transfer (CMT), TIG, and Plasma—with or without filler material.

Operators can easily manage and refine welding paths through the cobot controller, requiring minimal programming knowledge. The compact, mobile system can be quickly deployed or relocated to meet changing production needs, while built-in safety features protect operators. Industry 4.0 integration enables seamless data tracking for certification, analysis, and remote support.

Watch Guidetti Technology’s story:

Results at a glance:

- Improved production flexibility and responsiveness

- Enhanced product quality and process repeatability

- Faster order fulfillment for small batch jobs

- Operator labor reallocated to higher-value tasks

- Increased safety and ease of use for operators

Custom automated welding for flexible manufacturing

With OMRON collaborative robots, Guidetti Technology has created an automated welding solution that adapts to shifting production requirements in metal carpentry. Interested in how collaborative automation could streamline your operations? Let’s find the right solution for your needs.

Related insights

See all insights