Back to case studies

Grupo Antolin Transformed Operations with 100% Automated Component Transfers

A seamless shift from manual labor to a unified robotic workforce

Grupo Antolin, a global leader in automotive interiors, operates across 145 factories in 26 countries, supplying top car manufacturers with high-value components. At their Burgos plant in Spain, manual movement of interior parts between injection and assembly areas had long created inefficiencies and repetitive labor—challenges only heightened by the industry’s push toward electrification, digitalization, and sustainability.

To modernize workflows and unlock employee potential, Grupo Antolin set out to transform internal logistics. Their mission: deploy a scalable, flexible, and safe automation solution that would minimize manual handling and advance their Manufacturing 4.0 goals.

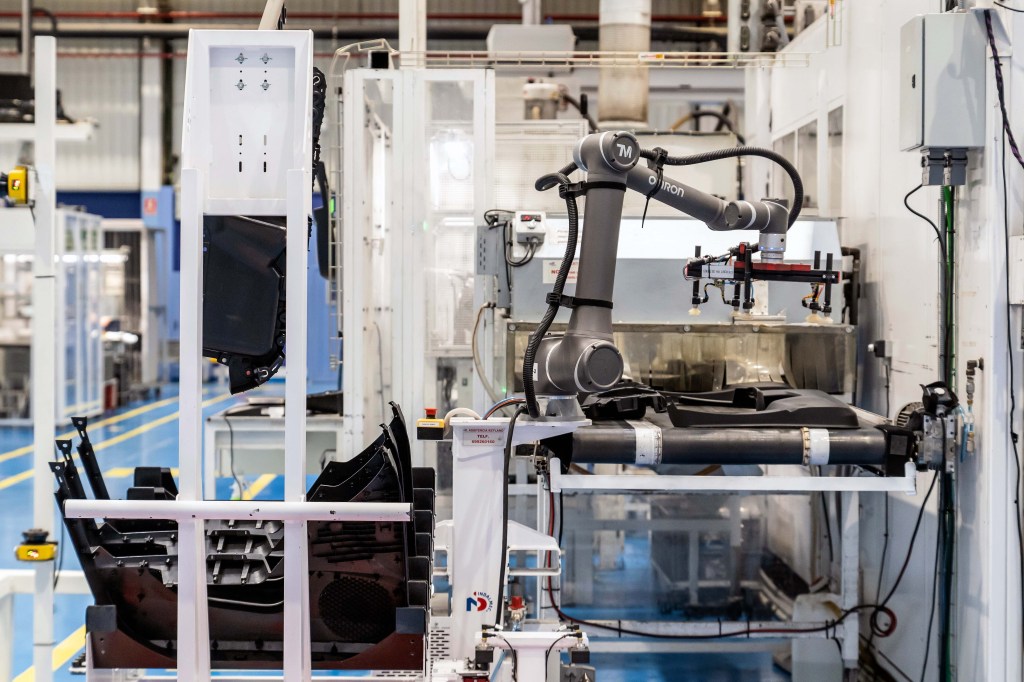

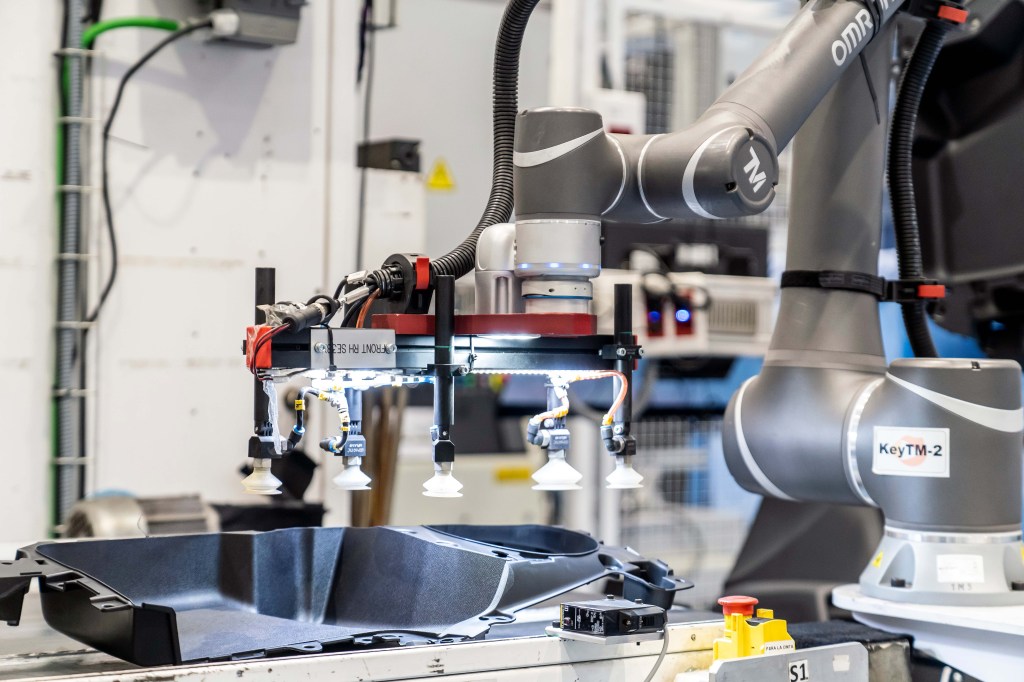

Partnering with OMRON, Grupo Antolin introduced a seamless blend of Autonomous Mobile Robots (AMRs) and collaborative robots (cobots). OMRON LD-250 AMRs now transport up to 250kg of components autonomously, navigating factory floors without any facility modifications. Meanwhile, OMRON TM12 cobots, equipped with advanced vision systems and safety lasers, handle precise loading, assembly, and inspection tasks right alongside operators.

This integrated approach to automotive manufacturing automation enables robots and people to work together seamlessly. Fleet management software coordinates AMR movements in real time, adapting instantly to production needs and allowing effortless scalability. The result is a fully automated, flexible system that connects injection and assembly, eliminates manual bottlenecks, and ensures maximum safety.

Since deploying OMRON’s solution, Grupo Antolin has achieved a new level of operational efficiency and workplace safety. Employees are now focused on complex, value-added tasks, while the automated system delivers consistent, reliable throughput—supporting both current production demands and future growth.

Watch Grupo Antolin’s story:

Download in: Italian | German | Spanish | French | Polish | Turkish

“The coexistence between Cobots and AMRs makes the system completely independent, seamlessly connecting the injection area to the assembly area — achieving automation that replaces labor-intensive processes while increasing safety and efficiency.” — Jaime Ruiz Alonso, Engineering Manager, Grupo Antolin

Results at a glance:

- 100% automated transfer of car interior components

- Seamless integration of AMRs and cobots

- Flexible, scalable automation for evolving production

- Enhanced workplace safety and efficiency

- Staff redeployed to value-added roles

- Progress toward Manufacturing 4.0 goals

Tailored automation for your operations

OMRON’s automation expertise empowered Grupo Antolin to achieve a new level of operational excellence. If you’re considering how robotics can streamline your own production, we’re here to share our insights—let’s start the conversation.

Related insights

See all insights