Back to case studies

Fischer Gears Automated 70% of CNC Feeding with OMRON Cobots

Overcoming CNC bottlenecks with collaborative robots

For years, Fischer Gears—a Danish manufacturer specializing in industrial and maritime gear production—struggled with a persistent bottleneck: manual feeding of CNC machines. This repetitive task not only slowed down production but also tied up skilled employees who could otherwise focus on more valuable work. As demand grew and efficiency became increasingly crucial, it was clear that a new approach was needed.

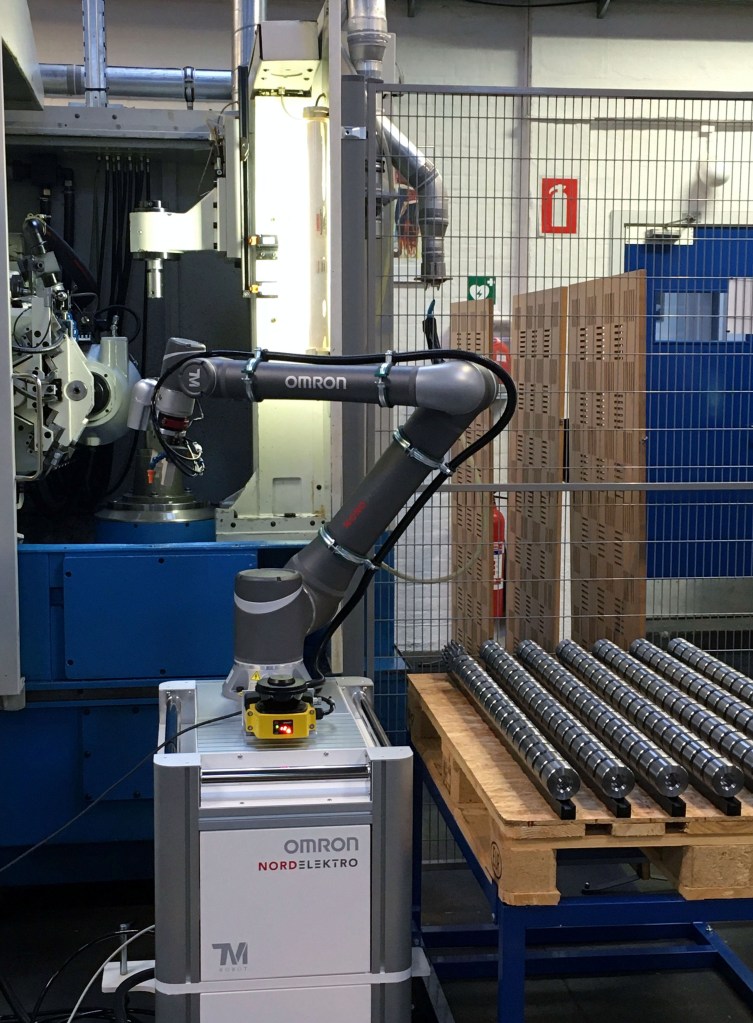

To address these challenges, Fischer Gears turned to automation. The company deployed two OMRON TM12 collaborative robots to handle the loading and unloading of metal parts across four CNC machines. This targeted solution quickly automated up to 70% of the feeding process, significantly increasing throughput and providing greater flexibility for both small and large production runs.

What sets this system apart is its use of advanced technology. The OMRON TM12 cobots are equipped with intelligent vision systems that accurately distinguish between raw and machined parts directly on the pallet, ensuring precise and reliable handling. Integrated safety scanners allow the robots to operate safely alongside employees without the need for protective fencing, maximizing available workspace and enabling true human-robot collaboration.

By automating CNC tending, Fischer Gears not only reduced manual labor but also empowered their team to focus on higher-value tasks—giving the company a competitive edge in a demanding industry. The result: increased productivity, improved job satisfaction, and a future-ready production line that can adapt as needs evolve.

Watch Fischer Gears’ story:

Download in: Spanish | French | Italian | German | Turkish

It’s not just another investment in robotics. Collaborative robots bring a whole new way of thinking because unlike traditional robots, the Omron TM robots don’t have to be hidden away behind a fence. And if this project is a success, these probably won’t be the last cobots we will use in the production line.” — Lars Bo Nielsen, Factory Manager, Fischer Gears

Results at a glance:

- 70% reduction in manual CNC feeding

- Increased efficiency and output on large production series

- Skilled operators freed for value-adding tasks

- Enhanced workplace safety with integrated Omron safety scanners

- Future-ready flexibility to adapt automation elsewhere in production

Tailored automation for your production

Fischer Gears’ success with machine tending robot automation shows how collaborative robots can address complex manufacturing challenges and unlock new efficiencies. If you’re exploring automation or interested in how similar innovations could fit your operations, let’s connect.

Related insights

See all insights