Back to case studies

How OMRON Helped Senova Produce 45 COVID-19 Tests Per Minute

Meeting unprecedented demand with medical production automation

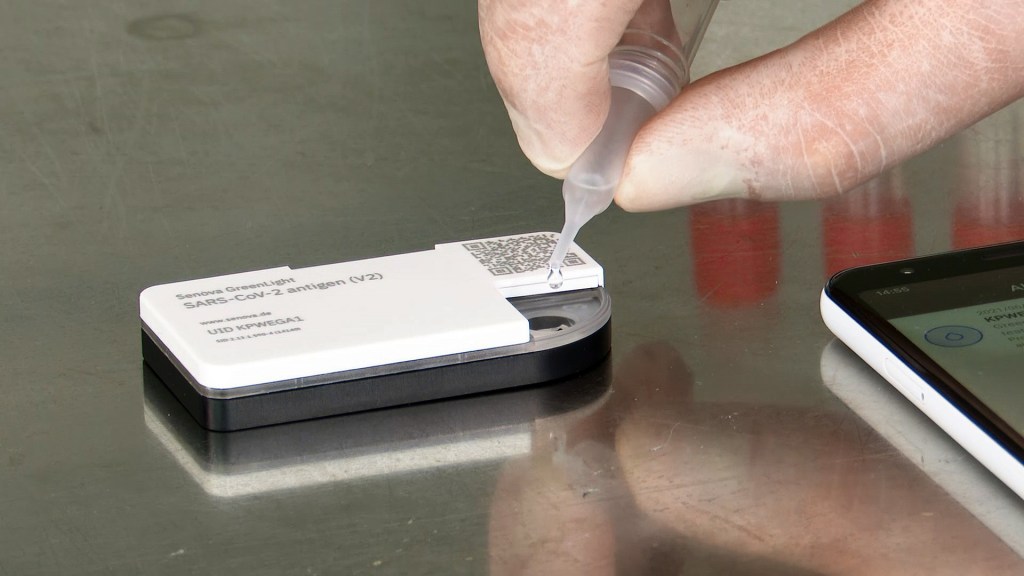

Senova, a German leader in rapid diagnostics, faced surging demand for Covid-19 antibody tests as global health needs soared. Traditional manual production could not keep pace, prompting Senova to partner with OMRON and Kraus Maschinenbau to implement a state-of-the-art Covid-19 test production automation system—dramatically accelerating the manufacturing process and ensuring reliable, high-quality output.

The new automated production line features OMRON’s eCobra SCARA robots, Quattro parallel robots, and TM5-700 collaborative robots, all seamlessly integrated with Kraus Maschinenbau’s cutting and packaging systems. This holistic approach to medical production automation enables precise assembly, handling, and packaging of rapid antibody tests, boosting throughput to an impressive 30–45 units per minute.

OMRON’s robotics solutions bring flexibility and consistency to every step of the process. The eCobra robots provide high-speed, high-precision handling in cleanroom environments, while the collaborative TM5-700 cobots safely assist with repetitive tasks, easing the pressure on employees and enabling 18-hour production days, six days a week. The result: Senova can now scale up output to meet surging demand, with new lines planned for further expansion.

Watch Senova’s story:

“The fast and uncomplicated implementation of this challenging project was only possible thanks to the perfect interaction and good chemistry between the customer, machine builder, and system and control supplier.” — Joachim Kraus, Managing Director, Kraus Maschinenbau GmbH

Results at a glance:

- 30–45 rapid antibody tests cut and packaged per minute

- Reliable, scalable production to meet global demand

- Enhanced quality and repeatability through precise automation

- Reduced manual labor and improved employee safety

- Flexible system ready for future growth and new product variants

Tailored automation for medical operations

With OMRON Robotics’ flexible and scalable solutions, manufacturers like Senova can rapidly adapt to changing market demands while maintaining exceptional quality and efficiency. Our expertise in industrial automation empowers you to streamline operations, boost productivity, and future-proof your facility.

Ready to elevate your operations? Contact us today to discover how OMRON can design the right automation solution for your unique needs.