Back to case studies

Cobot Integration Powers Flexible, On-Demand First Aid Kit Production at ESE International

Eliminating manual bottlenecks with targeted production automation

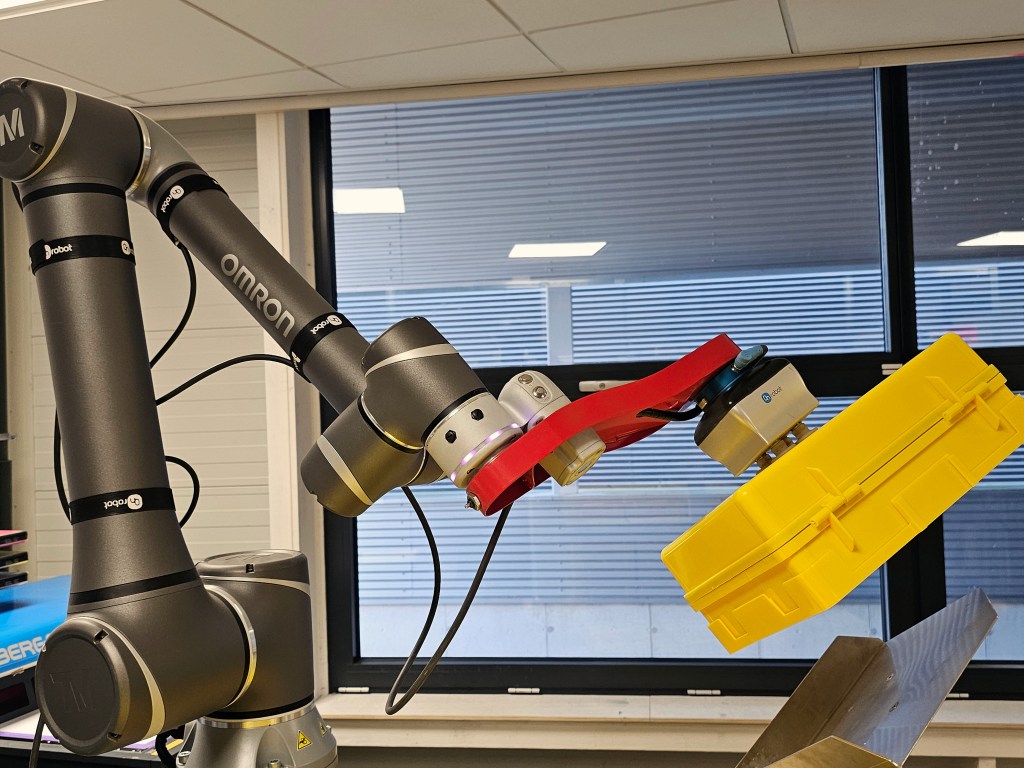

ESE International, a supplier of medical first aid kits, faced challenges with a labor-intensive printing process. Operators had to load and unload each kit box by hand for labeling. This manual approach slowed throughput, increased labor costs, and caused frequent bottlenecks—especially during peak demand and overnight shifts.

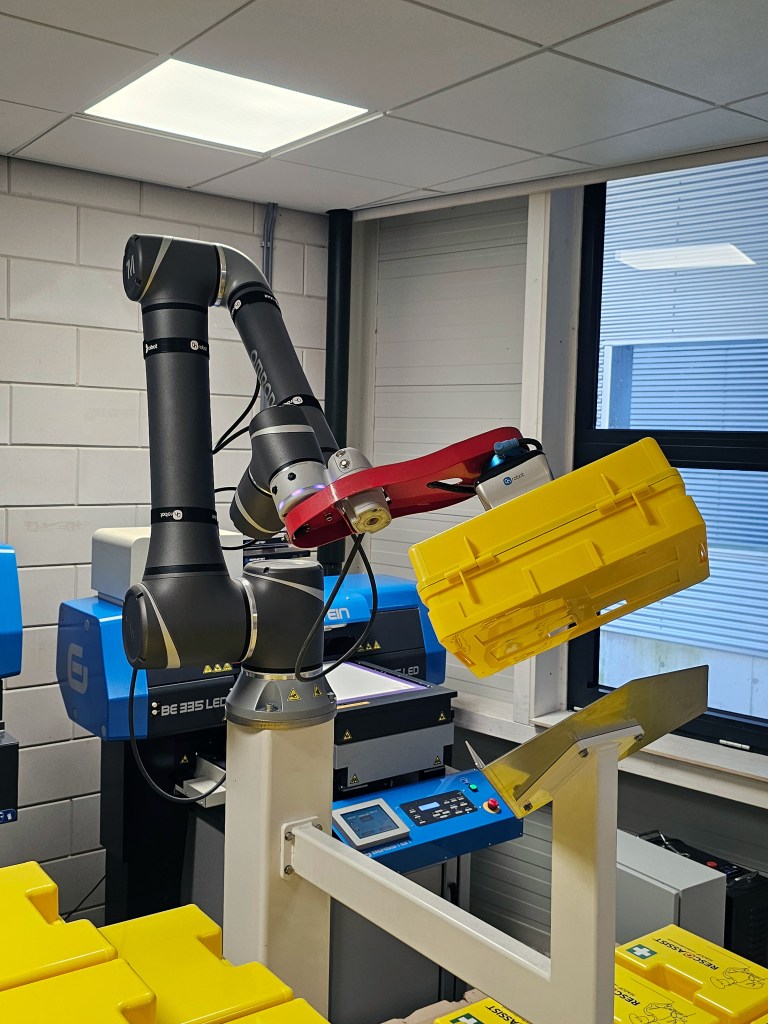

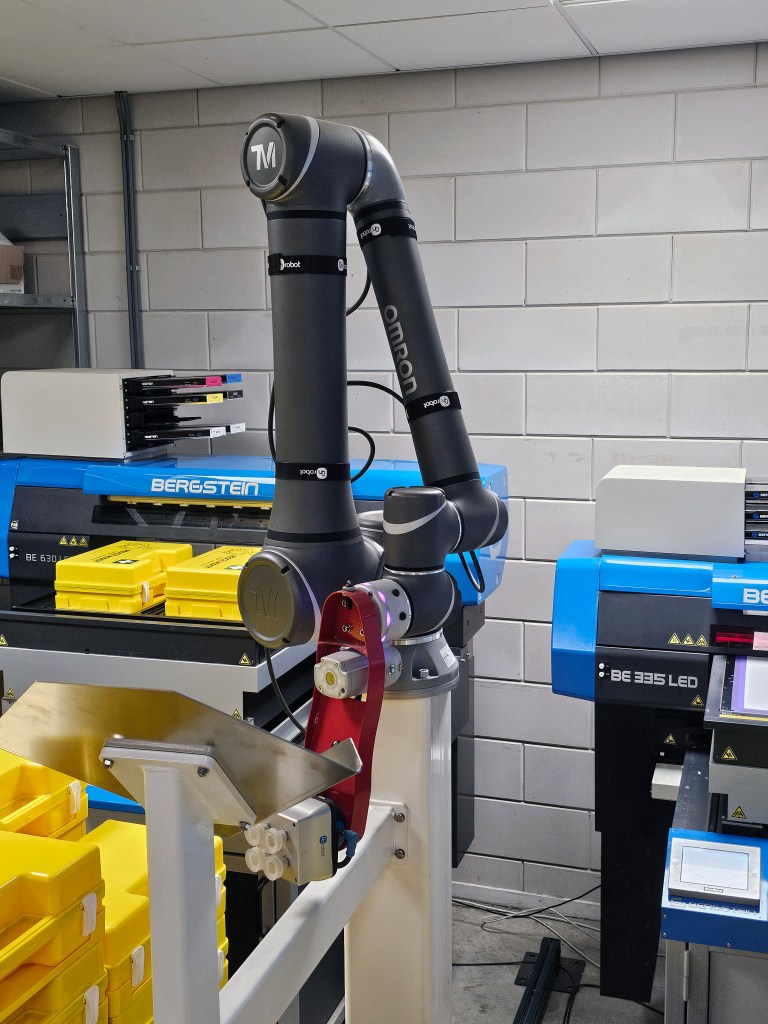

To overcome these inefficiencies, ESE International teamed up with OMRON, KOM Innovative Solutions, and Bergstein Digital B.V. to automate their printing process. The OMRON collaborative robot was chosen to manage the entire workflow, from picking up unprinted boxes to placing finished kits onto pallets. Bergstein Digital’s single-pass inkjet printers were integrated into the system, delivering fast, reliable labeling with minimal downtime. This flexible setup also allows for quick changeovers between different kit types, helping ESE International stay agile in a changing market.

With automation in place, tedious manual tasks are a thing of the past. Downtime has decreased, and overnight production now runs smoothly. Freed from repetitive work, employees can focus on more meaningful, high-impact projects. Thanks to these improvements, ESE International delivers faster responses and exceeds customer expectations with greater efficiency.

“The automation of the printing process has been a game-changer for us. By eliminating repetitive tasks, our employees are now able to focus on more value-added activities, making our operations more efficient.” — Joop Kaufman, Managing Director at ESE International B.V.

Results at a glance:

- Automated repetitive printing tasks

- Lowered labor costs and improved lead times

- Flexible changeover for multiple kit types

- Faster, more responsive order fulfillment

Tailored automation for medical manufacturing

OMRON’s robotic automation helped ESE International streamline manual box handling, minimize downtime, and run overnight production for first aid kits. By automating repetitive tasks, employees can focus on more valuable work. As a result, the company responds to customer needs faster and more efficiently. If you face similar production challenges, reach out to discover how OMRON can tailor an automation solution for your workflow.