Back to case studies

Automated Tray Handling Lowers Operator Exposure by 100% at Leica Geosystems

Solving hazardous epoxy handling with robotics and vision technology

At Leica Geosystems’ Odense facility, operators faced daily exposure to airborne epoxy fumes during manual tray handling—a process critical for precision filling but hazardous for worker health. Traditional methods put staff at risk of respiratory issues and limited production scalability, particularly as demand grew for Leica’s advanced sensors and surveying solutions.

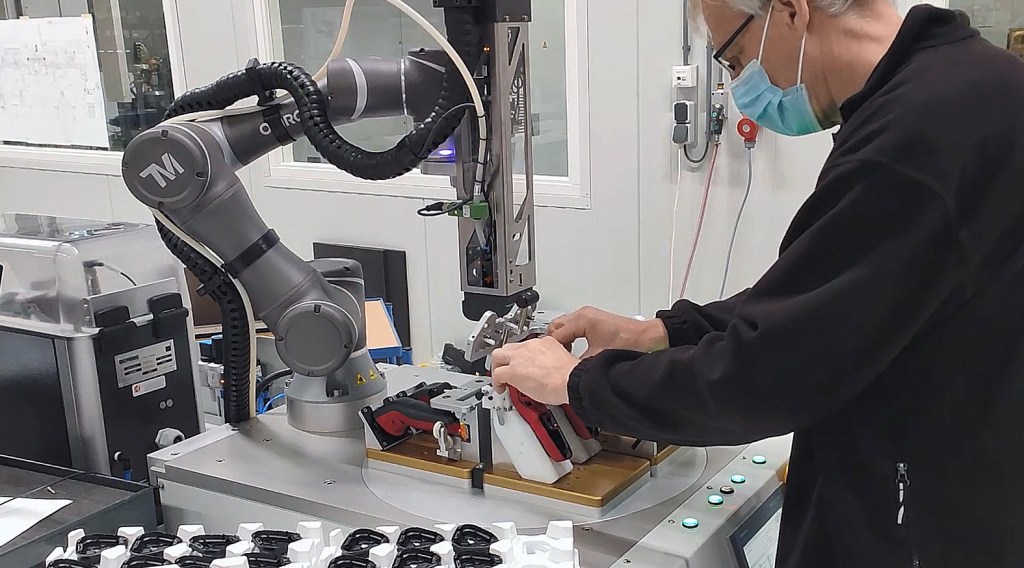

To eliminate these risks, Leica Geosystems implemented a robotic material handling solution centered on the OMRON TM12 collaborative robot, recommended and integrated by Gibotech. The system combines cobot-guided tray transfers with OMRON’s NX/NXIO machine control and vision technology, automating every step from rack retrieval to precise placement beneath epoxy dispensers. This approach keeps staff safely away from hazardous zones while also delivering consistent, accurate positioning for every fill cycle.

Following deployment, operator presence in hazardous areas dropped to zero, with all tray movement and epoxy filling now handled by collaborative robots. The result: a safer production environment, enhanced ergonomics, and an automation platform ready to grow with Leica’s expanding manufacturing needs.

Watch Leica Geosystems’ story:

Download in: Italian | German | Spanish | French | Polish | Turkish

“Our company expects to expand significantly in the future, so it was important to find a solution that can grow as the company grows. We particularly liked the flexibility and scalability of OMRON’s automation solution, and the implications it has for greater worker safety.” — Bent Andersen, Product Supply and Process Service Manager, Leica Geosystems

Results at a glance:

- Manual tray handling eliminated from epoxy filling process

- Continuous, unattended operation in hazardous areas

- Precise tray positioning ensures consistent material application

- Full process traceability through integrated automation

- Staff reassigned to higher-value tasks outside hazardous zones

Tailored automation for hazardous material handling

Robotic material handling at Leica Geosystems has removed operator from exposure to epoxy fumes and ensured consistent, unattended tray filling. If you’re facing similar safety or process challenges, we’re here to share practical insights and explore automation solutions tailored to your needs—let’s connect and find the right approach for your facility.

Related insights

See all insights