Product

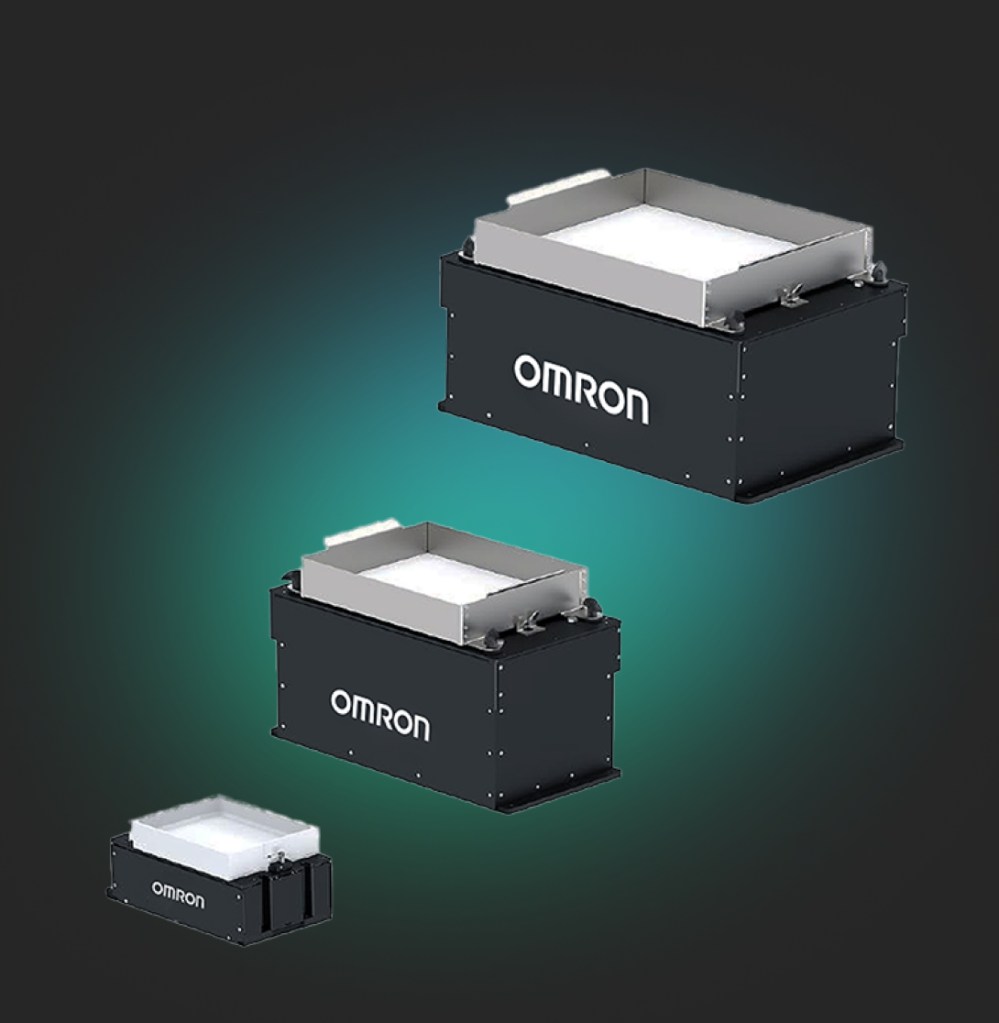

Industrial Part Feeders

Feed more, change over faster, and boost throughput—no custom fixtures. For pick‑and‑place and packaging, iPF flexible part feeders use patented 3‑axis vibration and vision to singulate 5–150 mm parts—reliably and gently, even for delicate components. Set up quickly in ACE, plug into OMRON robots and controls, and scale across lines. Compact, modular, cleanroom‑ready.

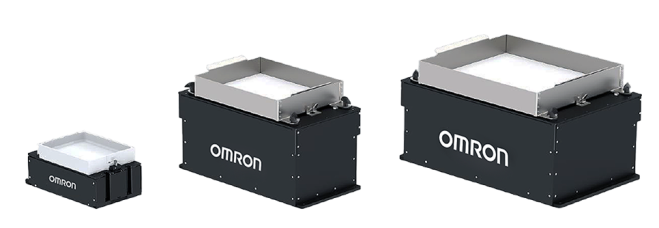

iPF-240

|

Part size range |

5 – 40 mm |

|

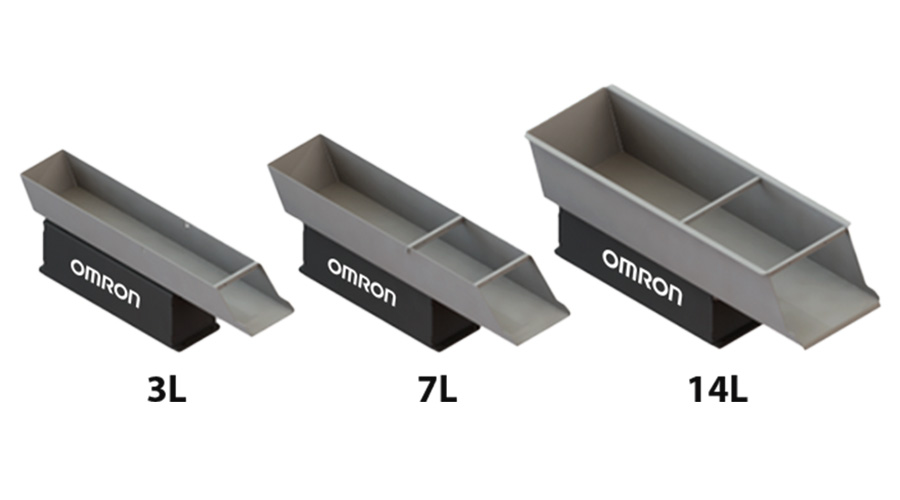

Hopper capacity |

3L / 12 kg max |

|

Platform surface options |

Flat, anti-roll 1 & 2, ESD |

|

Vibration frequency |

40 – 70 Hz |

|

Weight |

7.8 kg |

iPF-380

|

Part size range |

16 – 60 mm |

|

Hopper capacity |

7L / 12 kg max |

|

Platform surface options |

Flat, anti-roll 1 & 2, ESD |

|

Vibration frequency |

20 – 30 Hz |

|

Weight |

20 kg |

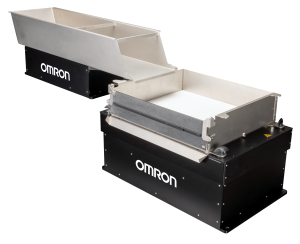

iPF-530

|

Part size range |

30 – 150 mm |

|

Hopper capacity |

14L / 19.5 kg max |

|

Platform surface options |

Flat, anti-roll 1 & 2, ESD |

|

Vibration frequency |

20 – 28 Hz |

|

Weight |

31 kg |

Gallery

Compare iPF models

Product

Part size range

Hopper capacity

Vibration frequency

Max part weight

Platform surface options

Weight

Communication

Controller integration

|

|

iPF-240 |

iPF-380 |

iPF-530 |

|---|---|---|---|

|

Part size range |

5 – 40 mm |

16 – 60 mm |

30 – 150 mm |

|

Hopper capacity |

3L / 12 kg max |

7L / 12 kg max |

14L / 19.5 kg max |

|

Vibration frequency |

40 – 70 Hz |

20 – 30 Hz |

20 – 28 Hz |

|

Max part weight |

400 g |

1500 g |

2000 g |

|

Platform surface options |

Flat Anti-roll 1 & 2 ESD |

Flat Anti-roll 1 & 2 ESD |

Flat Anti-roll 1 & 2 ESD |

|

Weight |

7.8 kg |

20 kg |

31 kg |

|

Communication |

Ethernet (TCP/IP) |

Ethernet (TCP/IP) |

Ethernet (TCP/IP) |

|

Controller integration |

Fully integrated with ACE software |

Fully integrated with ACE software |

Fully integrated with ACE software |

RELATED PRODUCTS

Automate your part feeding systems with industrial robots

Explore OMRON industrial robots designed to pair seamlessly with our feeders—unlocking flexible layouts, precise handling, and higher productivity across changing SKUs.

i4L

Compact SCARA robot for fast, precise assembly and material handling—ideal for electronics, packaging, and small parts handling.

i4H

High-speed SCARA robot with optional cleanroom, ESD, and food-grade versions for specialized part feeding tasks.

Viper

6-axis articulated robot for repetitive machine tending, assembly, and material handling with industrial part feeders.

iX3/Hornet

Parallel robots for ultra-fast pick-and-place operations in packaging, sorting, and high-speed assembly in food and pharma.

iX4/Quattro

Four-arm parallel robots for exceptional speed and accuracy in high-throughput applications like packaging, sorting, and handling.

eCobra

Flexible SCARA robot with advanced motion control for precise assembly, and material handling, complementing part feeding solutions.

Robotics Integrated Controller

A compact unit combining motion control, I/O, and communication for easy, precise robot automation and fast setup.

SOFTWARE

Smarter production starts with ACE

ACE software streamlines setup, tuning, and changeovers—cutting integration time and boosting uptime. Seamlessly paired with iPF part feeders and industrial robots for agile, scalable automation.

ACE Software

APPLICATIONS

Custom solutions for industrial automation

See how OMRON Robotics solves real manufacturing challenges—accelerating production, reducing downtime, and lifting first‑pass yield with tailored part‑feeding cells.

See all applications

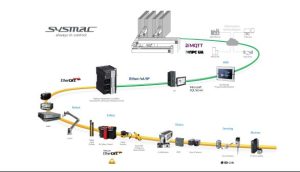

End-to-end automation

Explore OMRON’s full automation portfolio. Program and sync robots, safety, motion, and vision on one platform, then validate with integrated simulation. iPF feeders plug in natively for reliable singulation, synchronized picking, and fast changeovers.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

Robotics

Program industrial robots easily with Sysmac Studio. SmartController EX ensures seamless integration and high performance.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable your automated systems to seamlessly interact with their physical environment, ensuring precise performance.

Safety

Safety sensors enhance human-machine interaction, and Remote I/O minimizes costs and downtime for reliable networks.

Start optimizing your workflows today

Have questions? Let’s chat.

RESOURCES

Robotics expertise at your fingertips

Access resources, guides, software packages, and more to support your part feeding systems. Get tips and maintenance strategies for reliable performance.

Get iPF resources

SERVICE

Global robotics service and support

OMRON Robotics provides global safety, training, and support services to maximize uptime, improve efficiency, and ensure peak robot performance.

Learn more