iX3 & Hornet

Boost productivity in food, pharma, and commodity manufacturing with OMRON’s iX3 and Hornet parallel robots. Designed for high-speed pick-and-place, sorting, and packing, both feature hygienic, washdown-ready builds and handle up to 8 kg. Delta movements, vision, and conveyor tracking ensure precise, reliable performance. Choose iX3 for compact stainless steel, or Hornet for open-frame flexibility.

iX3-3-Axis

|

Max. working diameter |

1,130 mm |

|

Maximum payload |

8 kg |

|

Cycle times |

0.32-0.38 s |

|

IP rating |

IP20, IP65, IP67 |

|

Connectivity |

EtherCAT® via OMRON NJ501-R |

|

Programming environment |

Sysmac Studio |

iX3-4-Axis

|

Max. working diameter |

1130 mm |

|

Maximum payload |

3 kg |

|

Cycle times |

0.35-0.42 s |

|

IP rating |

IP20, IP65, IP67 |

|

Connectivity |

EtherCAT® via OMRON NJ501-R |

|

Programming environment |

Sysmac Studio |

Hornet-3-Axis

|

Max. working diameter |

1130 mm |

|

Maximum payload |

8 kg |

|

Cycle times |

0.32-0.38 s |

|

IP rating |

IP20, IP65, IP67 |

|

Connectivity |

EtherCAT®, Ethernet |

|

Programming environment |

ACE software, ePLC |

Hornet-4-Axis

|

Max. working diameter |

1,130 mm |

|

Maximum payload |

3 kg |

|

Cycle times |

0.35-0.42 s |

|

IP rating |

IP20, IP65, IP67 |

|

Connectivity |

EtherCAT®, Ethernet |

|

Programming environment |

ACE software, ePLC |

Gallery

APPLICATIONS

Built to handle your most demanding tasks

Discover how OMRON Robotics delivers tailored solutions to manufacturers worldwide, helping them tackle operational challenges with the advanced precision and speed of iX3 and Hornet robots.

See all applications

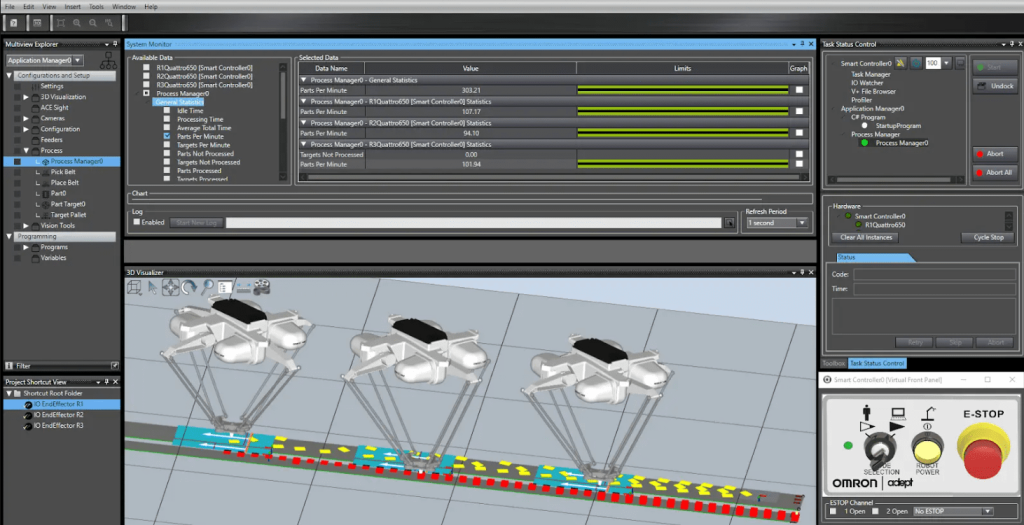

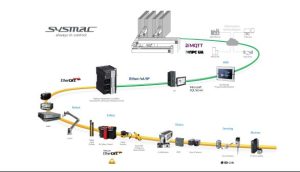

SOFTWARE

Smarter industrial production starts with ACE

Set up and synchronize parallel robots, conveyors, vision solutions, and motion control with OMRON’s ACE software. Achieve precise multi-pick operations, reduce cycle times, and maintain consistent accuracy for high-speed packaging and sorting.

Explore ACE

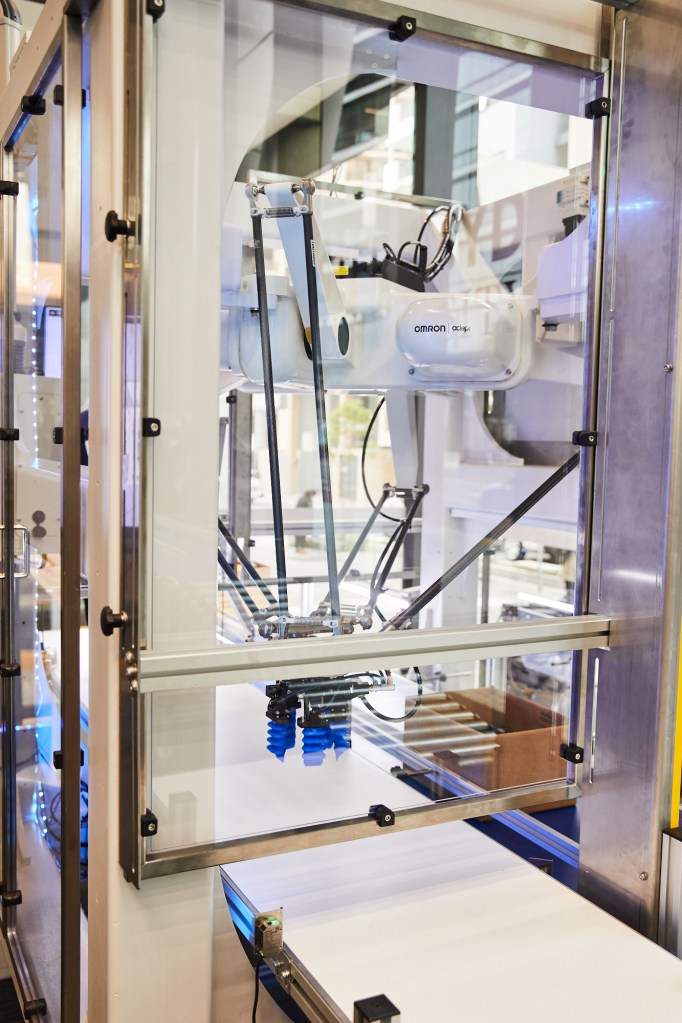

ROBOTICS CONTROLLER

Unified control for peak efficiency

Save time, reduce downtime, and adapt with ease using the Robotics Integrated Controller. Sync your iX3 and Hornet robots with automation systems for faster, smarter performance—all on one powerful platform.

Explore the solution

video

Automate your applications

Maximize productivity with Omron’s industrial automation solutions—easily program and sync robots, safety devices, and vision systems on one platform. Integrated simulation simplifies deployment and troubleshooting for seamless operations.

Motion

Servos minimize downtime and maintenance, while Industrial PCs ensure precise, reliable process control for automation.

Robotics

Program and integrate robots with the Robotics Integrated Controller, unifying automation and motion control for peak performance.

Control

Omron’s SYSMAC platform combines robotics and automation for flexible, scalable production.

Vision

OMRON’s IPC Application Controller supports 8 cameras for high-speed, precise image processing.

Safety

Safety sensors ensure human-machine collaboration, while Remote I/O cuts downtime and costs with reliable, real-time performance.

Optimize your workflows for faster results

Have questions? Let’s chat.

RESOURCES

Your iX3 and Hornet resource hub

Access technical documentation, guides, and updates in our download center to optimize your robots’ performance.

Get the latest updates

SERVICE

Global robotics service and support

OMRON Robotics provides global support and safety and training services to optimize your robot uptime, improve efficiency, and ensure top performance.

Learn more

Related insights

See all insights