i4L

Maximize precision and speed in assembly, pick-and-place, and packaging with the i4L SCARA robot. Designed for high-speed cycles and flexible mounting, the i4L handles up to 5 kg and comes in 350-, 450-, and 550-mm models. Its compact controller integrates effortlessly with OMRON’s ACE or Sysmac platforms, unifying robots, controls, vision, and feeding systems for streamlined automation.

i4-350L

|

Maximum reach |

350 mm |

|

Maximum payload |

5 kg |

|

Cycle times (at 2 kg) |

0.45-0.57 s |

|

Number of axes |

4 |

|

Connectivity |

EtherCAT®, Ethernet, PROFINET |

|

Programming environment |

Sysmac Studio and ACE |

i4-450L

|

Maximum reach |

450 mm |

|

Maximum payload |

5 kg |

|

Cycle times (at 2 kg) |

0.42-0.57 s |

|

Number of axes |

4 |

|

Connectivity |

EtherCAT®, Ethernet, PROFINET |

|

Programming environment |

Sysmac Studio and ACE |

i4-550L

|

Maximum reach |

550 mm |

|

Maximum payload |

5 kg |

|

Cycle times (at 2 kg) |

0.38-0.54 s |

|

Number of axes |

4 |

|

Connectivity |

EtherCAT®, Ethernet, PROFINET |

|

Programming environment |

Sysmac Studio and ACE |

Gallery

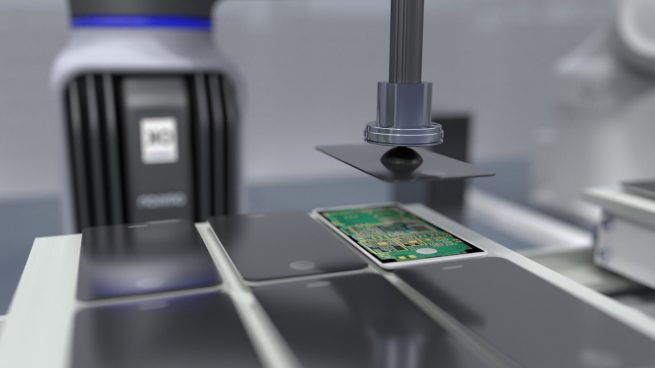

APPLICATIONS

Built for your application’s unique needs

Discover how manufacturers worldwide use OMRON SCARA robots to automate precision assembly, high-speed packaging, inspection, and material handling—solving complex challenges with tailored, efficient solutions.

See all applications

SOFTWARE

Smarter industrial production starts with ACE

Streamline setups, boost precision, and achieve smarter automation with OMRON’s ACE software. Designed for intuitive operation and maximum efficiency, ACE unlocks the full potential of your i4L SCARA robots, vision systems, and feeding solutions—giving you a clear competitive edge.

Explore ACE

ROBOTICS CONTROLLER

Integrated control for optimized performance

Achieve faster operations, reduced downtime, and greater flexibility with the powerful Robotics Integrated Controller. Streamline workflows and boost productivity by unifying i4L robotics and automation in one platform.

Explore the solution

video

FEEDING SOLUTIONS

Prevent jams and keep your production moving

Accelerate your workflow with fast, accurate part feeding for pick-and-place, packaging, and assembly. Advanced 3-axis vibration eliminates jams and adapts to any part—modular design integrates easily with ACE software.

Download brochure

iPF-240

Perfect for small parts (5-40 mm) like screws, washers, and electronics, its compact design ensures accuracy even in confined spaces.

iPF-380

Built for medium parts (15-60 mm) such as fasteners and joints, ensuring smooth alignment and reliable performance every time.

iPF-530

Ideal for large parts (30-150 mm) like bearings and housings, this robust feeder offers durability with anti-slip surfaces.

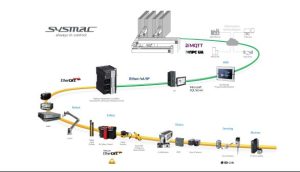

Smarter automation, faster results

Maximize efficiency with OMRON’s Sysmac Studio. Easily program and sync robots, vision, motion, and safety devices on one platform. Integrated simulation accelerates deployment and simplifies troubleshooting, helping you optimize your entire production line.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

Robotics

Program industrial robots easily with Sysmac Studio. SmartController EX ensures seamless integration and high performance.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable your automated systems to seamlessly interact with their physical environment, ensuring precise performance.

Safety

Safety sensors enhance human-machine interaction, and Remote I/O minimizes costs and downtime for reliable networks.

Start optimizing your production today

Have questions? Let’s chat.

RESOURCES

i4L documentation and resource hub

Access comprehensive resources and technical documentation in our support section to maximize the performance of your i4L robot.

View i4L resources

SERVICE

Global service and support network

OMRON Robotics provides global training, safety, and support services to ensure maximum robot uptime, peak efficiency, and optimal performance.

Learn more