Back to case studies

Coboloader Achieves 40 Boxes Per Minute in Automatic Packaging for FMCG Case Erectors

Addressing labor shortages and safety risks in carton loading with collaborative robots

FMCG producers often face challenges recruiting and retaining operators for loading cartons into tray forming machines, leading to inconsistent throughput and increased safety risks. Manual loading slows packaging processes and limits end-of-line efficiency and ergonomics.

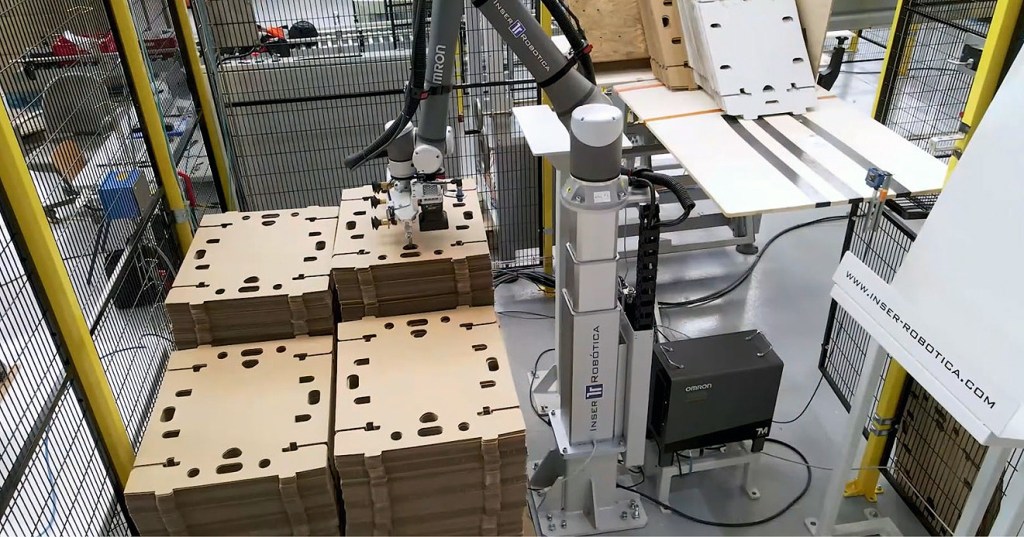

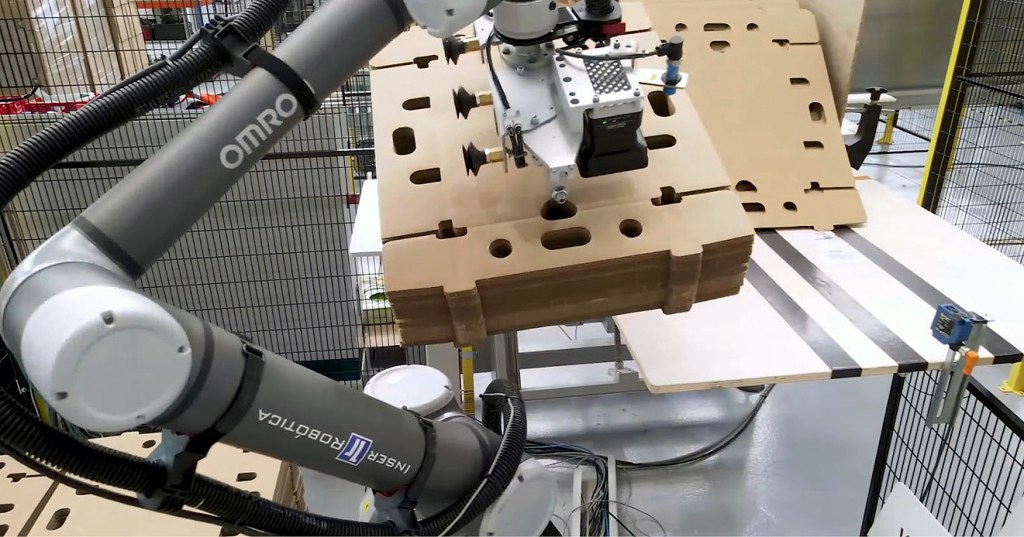

To address these issues, Inser Robótica S.A. developed the COBOLOADER, a collaborative robot cell for packaging lines. The system reliably places stacks of cartons onto belt conveyors feeding case erectors, adapting to a wide range of machine types. With a compact footprint of just 2,500mm by 1,800mm, COBOLOADER fits into tight spaces without disrupting existing layouts.

Powered by OMRON collaborative robots, the COBOLOADER delivers high productivity—processing up to 40 boxes per minute with minimal maintenance for up to 35,000 hours. Integrated safety scanners automatically slow operation when operators approach, ensuring safe collaboration. With energy consumption as low as 400W and less than 6 liters per hour of compressed air, the system supports sustainable operations.

Automating carton loading helps FMCG manufacturers boost productivity, enhance operator safety, and achieve faster ROI—delivering packaging that’s safer, more efficient, and ready to scale.

Watch Inser Robótica’s story:

Results at a glance:

- Up to 40 boxes per minute loaded onto case erector conveyors

- 35,000 hours of maintenance-free operation

- Small footprint: 2,500mm x 1,800mm

- Energy-efficient: 400W power, <6L/hr compressed air

- Enhanced safety and ergonomic improvements for operators

Tailored automatic packaging for FMCG manufacturers

Coboloader robots make case erector loading faster, safer, and more energy-efficient. With rapid integration and adaptable design for any production line, Inser Robótica and OMRON deliver automation that meets real FMCG challenges. If you’re interested in automating your packaging process, our team can help you achieve reliable, high-performance results for your project—let’s explore what’s possible together.

Related insights

See all insights

Collaborative Palletizer Handles Up to 8 Boxes per Minute, Accelerating ROI for Industrial Manufacturers

Data-Driven Automated Packaging Boosts Cleca’s Broth Line Output by 8%

RB1200 Cobot Palletizer Reduces Footprint by 60% and Cuts Costs by 50% with Automated Palletizing