Back to case studies

VOLA’s Made-to-Order Success with Nine OMRON LD Series AMRs

A shift from traditional conveyors to Autonomous Mobile Robots

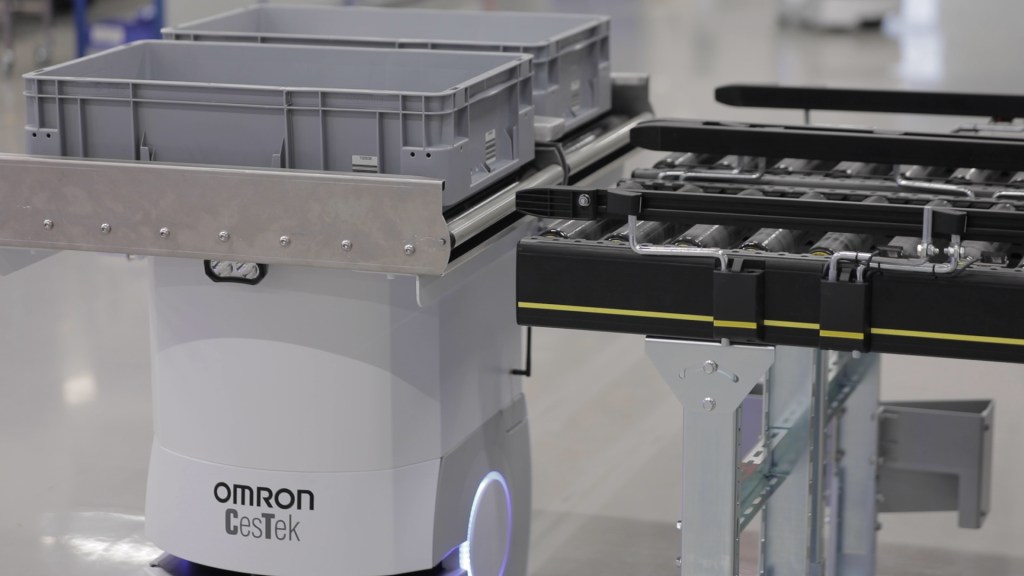

VOLA, a Danish leader in luxury sanitary and kitchen fittings with over 50 years of experience, is renowned for quality, adaptability, and timeless design. To meet rising demand and maintain flexibility in its single-piece production process, VOLA transformed its made-to-order workflow by integrating nine OMRON LD Series Autonomous Mobile Robots (AMRs)—one of the largest deployments in the Nordics. These AMRs have replaced traditional roller conveyors, efficiently transporting components and finished products between the high-bay warehouse and assembly hall.

Managed by OMRON’s Enterprise Manager system, FLOW Core, the LD series AMRs seamlessly coordinate movements, schedule charging, and optimize traffic flow. This innovative shift boosts efficiency in logistics and warehousing while preserving VOLA’s legacy of craftsmanship, uniting advanced technology with tradition to create a seamless, precision-driven workflow.

Watch VOLAs story:

Download in: Spanish | French | Italian | Turkish

“There are only a few robot manufacturers that are able to handle the advanced fleet management of so many robots. The solution by Omron is by far the best that we’ve seen in the market, and this is why we opted for the LD mobile robots,” – Peder Nygaard, Chief Operating Officer, VOLA A/S

Results at a glance:

- Flexible, made-to-order production enabled by nine LD Series AMRs

- Improved workflow efficiency and adaptability

- Safe, collaborative environment for people and robots

- Scalable system with the potential for future expansion

Tailored automation for your operations

With OMRON Robotics’ flexible solutions, manufacturers like VOLA can adapt quickly and efficiently to changing demands. Curious how our solutions could improve your operations? Let’s find the right robot together.