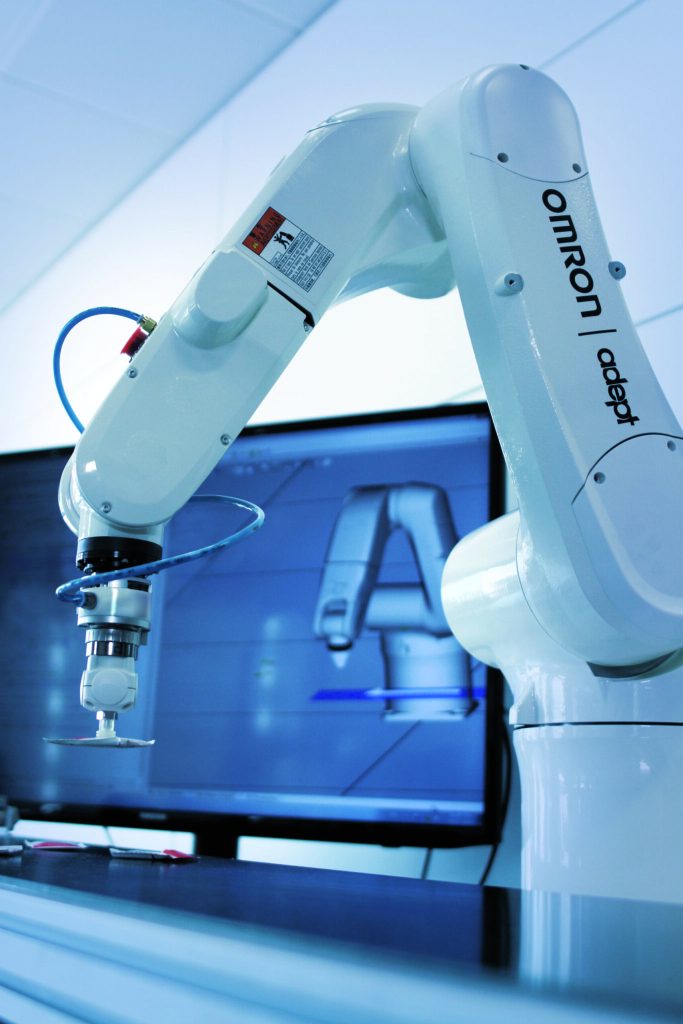

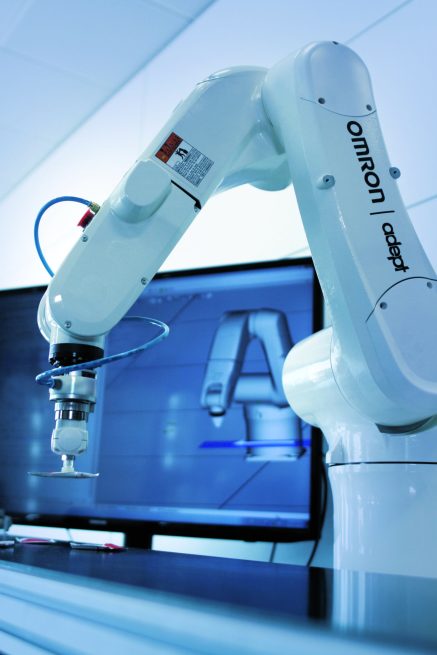

Viper

Move faster, hit tighter tolerances, and redeploy without the rework. Viper six‑axis robots combine high speed with precise motion to cut cycle time and boost quality. Set up in ACE or Sysmac Studio, connect to OMRON controllers or ePLC, and scale with vision and conveyor tracking. Compact, flexible, and cleanroom/IP‑ready—Viper fits your line today and grows with you.

Viper 650

|

Maximum reach |

653 mm |

|

Maximum payload |

5 kg |

|

Repeatability |

±0.02 mm |

|

No. of axes |

6 |

|

Connectivity |

EtherCAT® to NJ501-R or Ethernet |

|

Programming environment |

ACE / Sysmac Studio |

Viper 850

|

Maximum reach |

855 mm |

|

Maximum payload |

5 kg |

|

Repeatability |

±0.03 mm |

|

No. of axes |

6 |

|

Connectivity |

EtherCAT® to NJ501-R or Ethernet |

|

Programming environment |

ACE / Sysmac Studio |

Gallery

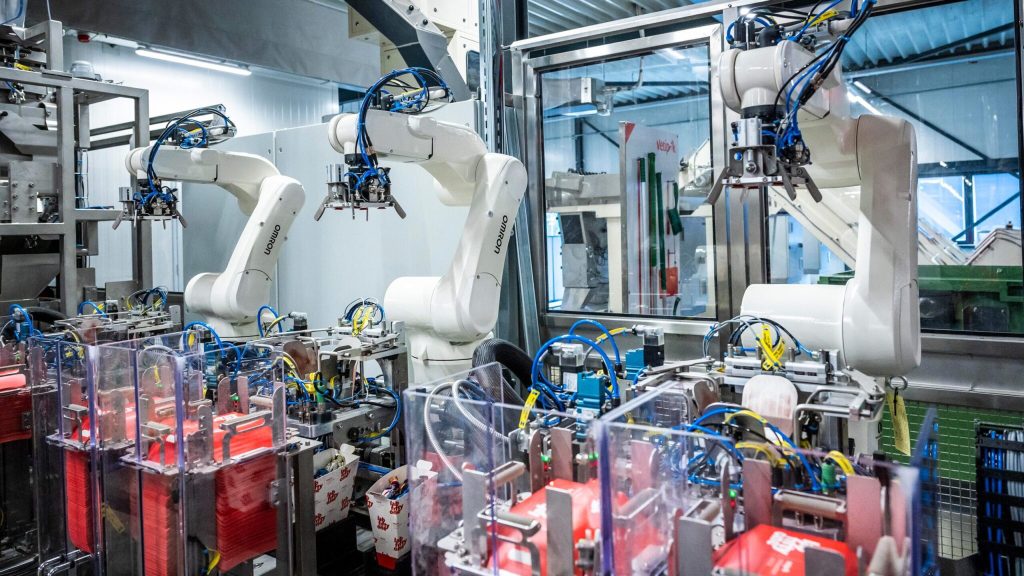

APPLICATIONS

Built to solve your manufacturing challenges

See how OMRON Robotics empowers manufacturers worldwide with proven solutions that enhance productivity, streamline workflows, and meet diverse application requirements.

See all applications

SOFTWARE

Elevate your production with ACE

Streamline operations with ACE software—simpler integration, higher precision, and optimized workflows that save time and cut costs, unlocking Viper robots’ agility and efficiency.

Explore ACE

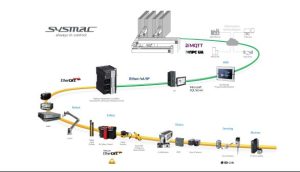

ROBOTICS CONTROLLER

Unified control for superior performance

Save time, cut downtime, and adapt fast with the Robotics Integrated Controller. Synchronize Viper robots and automation systems for faster, more efficient operations—all on one platform.

See the controller

video

FEEDING SOLUTIONS

Keep your line moving with precision feeding

Keep your operations running smoothly with advanced part feeding for pick-and-place, packaging, and assembly. Prevent downtime and increase efficiency with 3-axis vibration technology and modular, ACE-compatible systems.

Download brochure

End-to-end automation

Explore the full automation portfolio with OMRON’s industrial automation solutions. Easily program and sync robots, safety devices, and vision systems on one platform. Integrated simulation simplifies deployment and troubleshooting for seamless operations.

Motion

Servos minimize downtime and maintenance, while Industrial PCs ensure precise, reliable process control for automation.

Robotics

Program and integrate robots with the Robotics Integrated Controller—unifying automation and motion control for peak performance.

Control

Unify robotics and automation with the Robotics Integrated Controller for flexible scaling and precise control.

Vision

OMRON’s IPC Application Controller supports 8 cameras for high-speed, precise image processing.

Safety

Safety sensors ensure human-machine collaboration, while Remote I/O cuts downtime and costs with reliable, real-time performance.

Start optimizing your operations today

Have questions? Let’s chat.

RESOURCES

Your Viper resource hub

Access technical documentation, guides, resources, and software updates to fully optimize your robot’s performance.

Get the latest updates

SERVICE

Global robotics service and support

Benefit from OMRON Robotics’ global safety, training, and support services—maximizing robot uptime, boosting efficiency, and ensuring peak performance across your operations.

Learn more