LD-250

The LD-250 is a robust AMR, transporting up to 250 kg with advanced navigation, real-time mapping, efficient route planning, and optional ESD protection to streamline material handling operations.

LD-250

|

Maximum payload |

250 kg |

|

Maximum speed |

1200 mm/s |

|

Run time |

13 h (no payload), 10 h (full payload) |

|

Charging time |

2 h 10 m (for 20–80% charge) |

|

Maximum slope |

1.7° / 3% incline |

|

Control interface |

Gallery

SOFTWARE

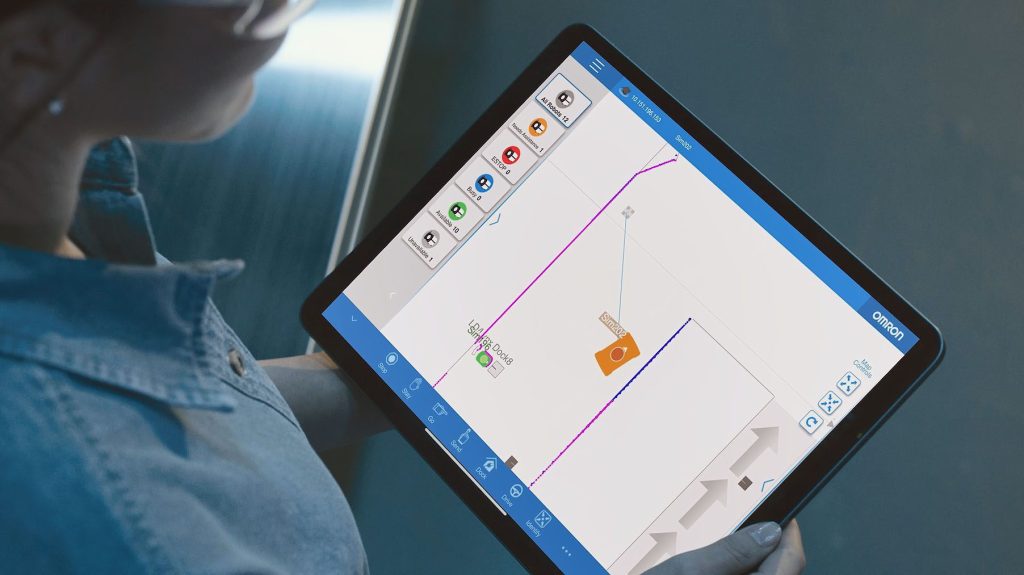

Optimize your fleet’s performance with Flow Core

Take control of up to 100 OMRON AMRs with FLOW Core. Streamline task creation and route planning while leveraging advanced job assignment, motion control, and traffic management to optimize workflows and drive productivity—unlock the full power of your mobile robot fleet.

Learn More

APPLICATIONS

Tailored AMR solutions for efficient transport

From parts delivery and finished goods transport, OMRON Robotics solves logistics and material handling challenges with customized AMR solutions that enhance safety, adaptability, and efficiency for streamlined operations.

See all applications

MANIPULATOR SOLUTION

Collaborative production starts with MoMa

Transform your operations with Mobile Manipulator applications. Seamlessly combine collaborative and mobile robotics to automate transport and picking tasks, while enhancing flexibility, productivity, and workflow precision.

Learn more about MoMa

video

Automate your applications

Streamline your workflows with Omron’s industrial automation solutions. Seamlessly program and synchronize robots, safety, and vision systems on one platform. Integrated simulation ensures easy deployment and efficient operations.

Motion

Servos ensure efficient line movement, reducing downtime and maintenance for smoother, more reliable operations.

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units integrate your production line, maximizing productivity while saving space with built-in systems.

Vision

Cameras and sensors adapt to your environment, enabling smooth, accurate, and high-quality automated processes.

Safety

Safety sensors ensure seamless human-machine collaboration, reducing risks and enhancing workplace safety.

Start optimizing your production today

Have questions? Let’s chat.

RESOURCES

Your go-to resource hub

Optimize workflows and maintain top fleet performance with the latest FLOW Core updates and product documentation.

Get the latest updates

SERVICE

Global support and service network

OMRON Robotics provides worldwide service, support, and training to ensure your mobile fleets operate efficiently and meet their full potential.

Learn more

Related insights

Get more insights