Back to case studies

Personal Care Manufacturer Reduces Costly Downtime with OMRON TM5-700 Cobot

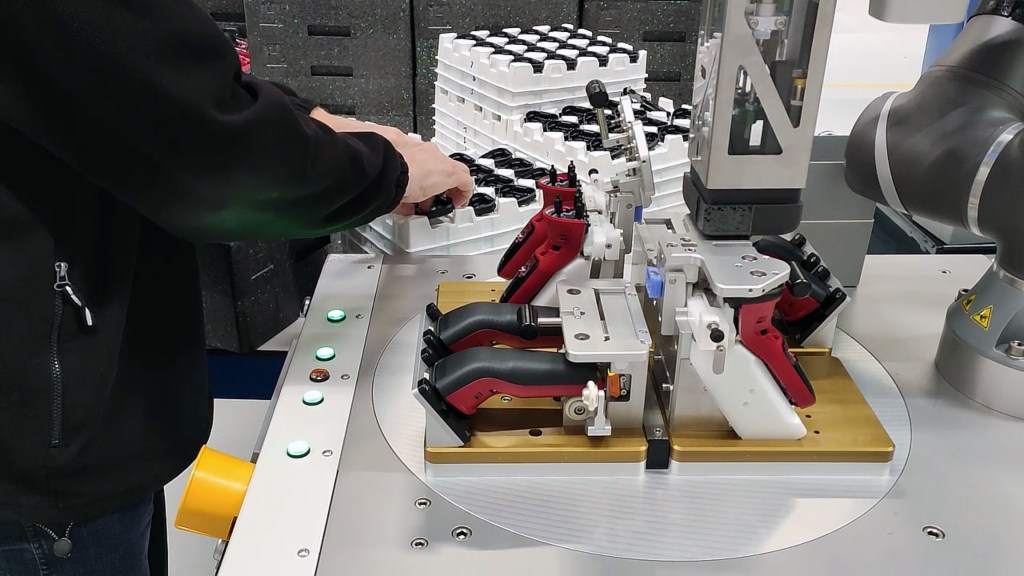

Solving manual changeover delays in high-mix personal care production

A leading personal care manufacturer was challenged by regular delays on its electric shaver assembly line. Frequent product changeovers required manual tool swaps and lengthy retraining, resulting in lost production hours and inconsistent output. Skilled operators spent significant time adjusting fixtures and verifying screw fastening, while each new product variant introduced risk of human error and extended downtime.

To address these bottlenecks, OMRON integrated the TM5-700 collaborative robot into the assembly automation process. The cobot’s intuitive programming interface enabled operators to set up new product types in minutes, eliminating the need for specialized training. Single-minute exchange of dies (SMED) became standard practice, with the cobot automatically adapting to multiple product formats and executing precise screw fastening for every unit.

The benefit was immediate and measurable. Changeover time dropped by 80%, allowing the manufacturer to respond rapidly to market demand and introduce new models without sacrificing throughput. Assembly automation also improved process consistency, with the TM5-700 delivering repeatable quality and reducing rework. Operators now focus on higher-value tasks, with the cobot handling routine assembly steps safely and efficiently.

Watch the story:

“OMRON cobots are designed to be supremely flexible, both in the way they are simple to program, and in the way that they can be used. Here, the customer can achieve single-minute exchange of dies (SMED), moving from one product type to another extremely quickly.” — Barry Oorbeek, Key Account Manager Industry Solutions at OMRON Benelux

Results at a glance:

- Noticeably faster changeovers between electric shaver models

- Consistent, repeatable assembly quality across product types

- Rapid onboarding for operators with user-friendly cobot programming

- Flexible assembly automation supporting diverse production needs

- Safer working environment with reduced manual handling

Optimized assembly automation for fast and error-free changeovers

OMRON’s assembly automation solutions empower manufacturers to optimize changeovers, boost product quality, and make better use of skilled labor. For operations facing frequent model changes, collaborative robots offer a proven path to greater efficiency and reliability. If you’d like to discuss your production goals or explore practical solutions, our team is available to share expertise and insights—let’s connect.

Related insights

See all insights