Back to case studies

LITMAT Increased Magnet Assembly to 180 Caps Per Hour with Automation

Solving manual assembly bottlenecks with precision automation

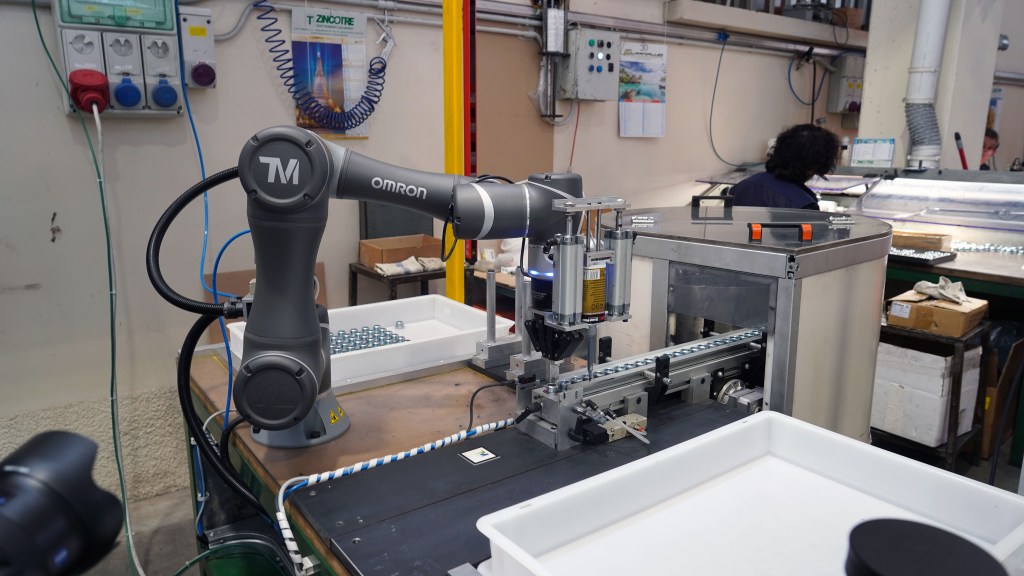

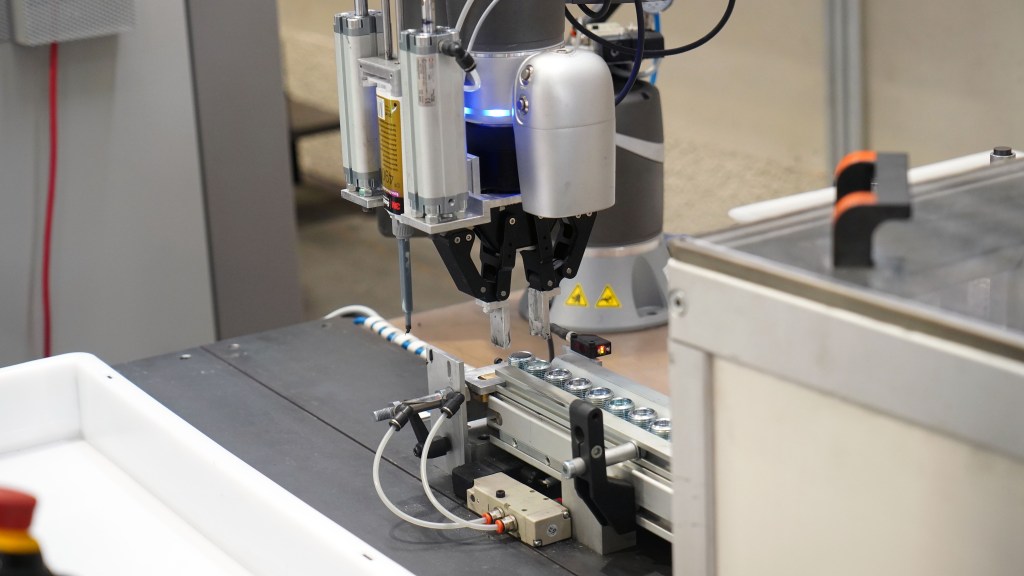

LITMAT, a leader in metal drain plugs for the automotive sector, faced challenges in scaling up magnet assembly without sacrificing precision or consistency. To address these bottlenecks, LITMAT integrated an OMRON TM5-700 collaborative robot for assembly, automating the entire magnet insertion and gluing process for its drain plugs.

The collaborative robot for assembly performs every step with repeatable accuracy: applying adhesive, inserting magnets, and verifying glue quantity using an integrated camera. All production data is centrally managed by an OMRON NX102 PLC, providing real-time oversight and seamless integration with LITMAT’s manufacturing execution system. Operators can monitor part status, reject rates, and adjust key parameters—such as cap or magnet height—directly from the user interface, ensuring rapid changeovers without costly tooling.

Safety and collaboration were key requirements. The system uses safety barriers and collaborative mode, allowing staff to work alongside the cobot while remaining protected. This automation has enabled LITMAT to assemble 180 caps per hour, totaling 1500 parts per shift, with consistent pressure and placement that guarantees high product quality. The result: fewer defects, reduced labor costs, and a more flexible production line ready to adapt to customer specifications.

Watch LITMAT’s story:

Results at a glance:

- 180 caps assembled per hour, 1500 parts per shift

- Consistent assembly quality and fewer defects

- Fast changeovers with no need for new tooling

- Enhanced safety and collaboration on the factory floor

Tailored automation for your operations

LITMAT’s investment in collaborative robot automation has delivered measurable results—higher throughput, improved product quality, and greater flexibility to meet customer needs. Interested in enhancing your own assembly line? Contact us to discover how our automated solutions can boost efficiency and add value to your operations.

Related insights

See all insights