Back to case studies

Automated Machine Tending Increases Capacity and Efficiency at Laser Quality Markings

From manual waiting to reliable, unattended production

Laser Quality Markings, based in Halikko, Finland, is renowned for delivering permanent, precise laser markings on a wide variety of materials for clients demanding exceptional accuracy and durability. As orders surged, the company faced a critical challenge: a shortage of manual labor threatened production capacity, while skilled operators spent excessive time on repetitive machine tending tasks instead of focusing on creative, business-critical work.

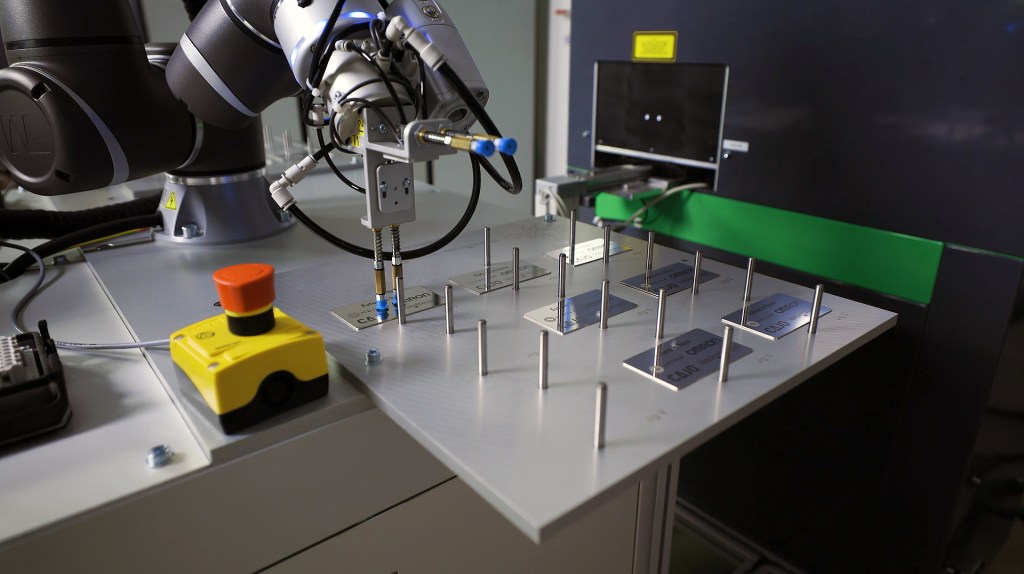

To overcome these obstacles, Laser Quality Markings partnered with Heina Ltd to deploy an automated machine tending solution using an OMRON TM5-900 collaborative robot. Integrated with a Cajo laser marking device and supported by an OMRON NX1P2 controller, NA5 interface, and OS32C safety scanner, the cobot now picks up raw materials from a feeder, loads them into the laser marking station, and removes finished parts automatically. The system even alerts operators when the feeder station needs refilling, allowing production to run uninterrupted for extended periods.

The results have been dramatic: long waiting periods for operators have been eliminated, freeing them to concentrate on design and other high-value tasks. Production continues seamlessly—even during sick leave or holidays—ensuring greater efficiency, reliability, and flexibility. Labor costs have dropped, and the company is now positioned to expand capacity further by adding more automated cells in the future.

Watch Laser Quality Markings’ story:

Download in: Italian | German | Spanish | French | Polish | Turkish

“We wanted to improve our production capacity and reduce waiting times while also being able to assign more business-critical tasks to our operators. Previously, they had to endure long waiting periods while operating the laser machine manually.” — Kim Nivalinna, CEO, Laser Quality Markings

Results at a glance:

- Increased production capacity and reduced waiting times

- Operators redeployed to creative and business-critical tasks

- Reliable, uninterrupted production even during staff absences

- Lower labor costs and higher operational efficiency

- Flexible platform for expanding with additional automated cells

Tailored automation for machine tending applications

OMRON worked closely with Laser Quality Markings to design an automation solution tailored to their unique production needs. By integrating collaborative robotics and safety systems, we enabled seamless, unattended laser marking—freeing up skilled staff and ensuring reliable output. If you’re looking for a partner to help you solve your own production challenges with custom automation, let’s connect.

Related insights

See all insights