Processing

Automate tasks with OMRON’s industrial robots for processing—efficient, flexible, and precise.

Consistent throughput from start to finish

Automate every stage of processing with robots. From machine tending and sorting to fitting, fastening, and palletizing, our solutions deliver consistent quality and high throughput. Easily adapt to new SKUs and scale production without retooling, freeing your team to focus on innovation and value-added tasks.

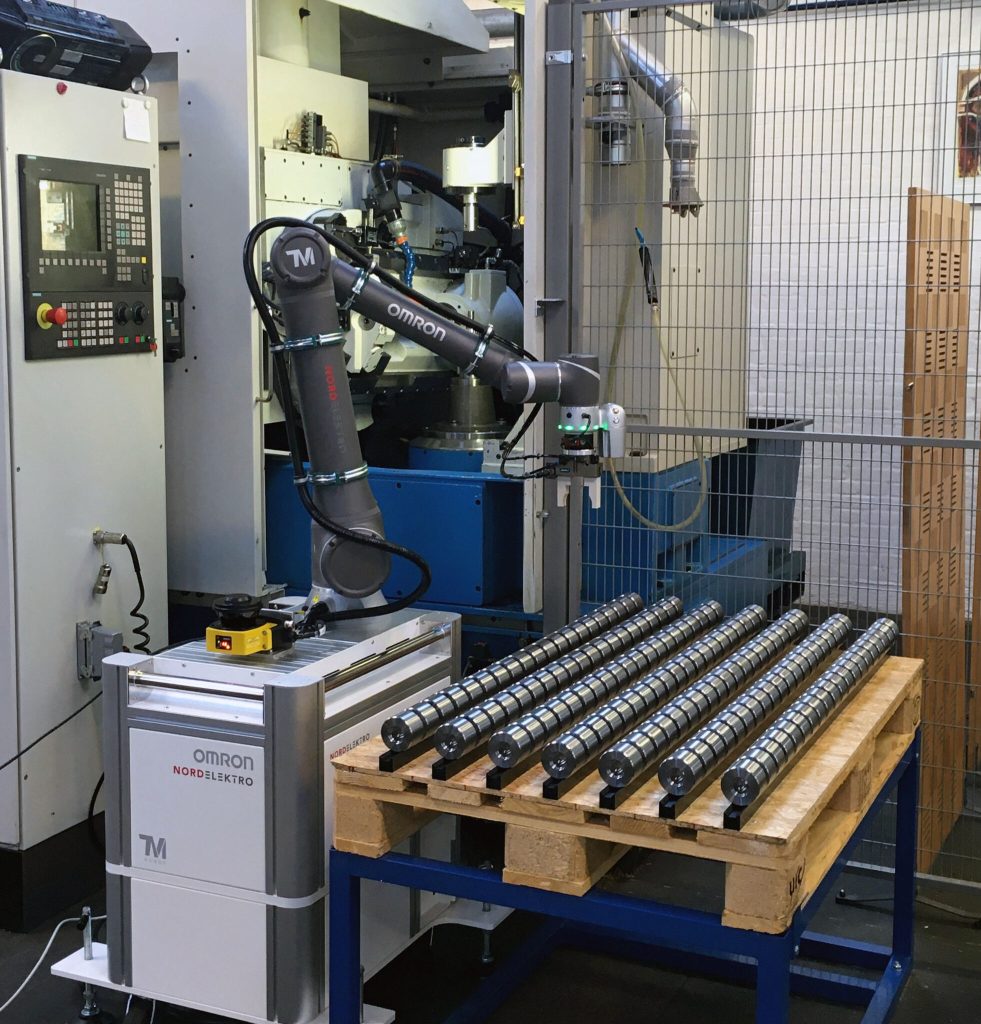

Automated machine tending

Maximize equipment utilization and operator safety with OMRON’s Viper and TM S Series robots. These high-precision solutions load and unload CNCs, presses, and molding machines, monitor machine status in real time, and keep production running around the clock—reducing downtime, cutting labor costs, and empowering your staff to focus on critical production tasks.

High-speed pick & place

Accelerate throughput and maintain product integrity with SCARA, and Parallel Axis robots for high-speed pick & place. Engineered for rapid cycle times and precise placement, these robots optimize material preparation, sorting, and assembly—especially in fast-moving consumer goods, food, and electronics manufacturing, reducing defects, and improving line efficiency.

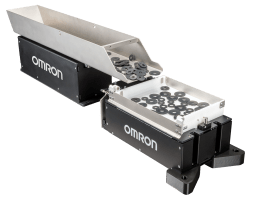

Flexible sorting & bin picking

Tackle mixed-model production with OMRON’s part feeding, bin picking, and sorting solutions. Our advanced iPF feeders present randomly oriented parts for Viper and SCARA robots to pick and place, reducing manual sorting and keeping production flowing smoothly for increased productivity and traceability.

Precise part fitting & fastening

Achieve repeatable quality and tight tolerances in processing with Viper, TM S Series, and SCARA robots. These robots automate complex part fitting, fastening, and sub-assembly operations, ensuring consistent torque, alignment, and traceability throughout your process. Ideal for automotive, electronics, and medical device manufacturing, we help you improve first-pass yields and scale production efficiently.

Automated palletizing & packaging

Streamline your end-of-line operations with automated palletizing and packaging solutions. Our collaborative and industrial robots stack, wrap, and prepare goods for shipment, while Autonomous Mobile Robots (AMRs) handle lineside pickup, transport, and storage. This integrated approach boosts throughput, reduces manual handling and ergonomic risks, and supports just-in-time logistics for smarter, leaner supply chains.

Collaborative welding & fabrication

Enhance metalworking with OMRON’s automated welding solutions. Our collaborative robots handle repetitive welding tasks across diverse metals, supporting MIG (Short/Spray, Pulsed, LSC, PMC, STEEL), TIG, Plasma, and Cold Metal Transfer processes—with or without filler material. Intuitive controls allow quick setup and changeovers, boosting output, freeing skilled welders, and ensuring operator safety, while seamless data tracking supports certification and analysis.

Flexible, adaptable automation

Combine the flexibility of AMRs with advanced manipulation using Mobile Manipulators. MoMas autonomously navigate your facility, execute pick & place, material transfer, and replenishment tasks, and adapt to production changes in real time—bridging the gap between fixed automation and dynamic manufacturing.

Start optimizing your production today

Have questions? Let’s chat.

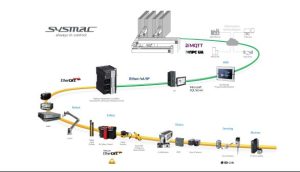

Unlock seamless automation

Manage robots, PLCs, safety devices, and vision systems from a unified platform. Integrated simulation accelerates deployment and troubleshooting, ensuring smooth and efficient operations every step of the way.

Motion

Servos minimize downtime and maintenance, while Industrial PCs ensure precise, reliable process control for automation.

Robotics

Program and integrate robots with the Robotics Integrated Controller—unifying automation and motion control for peak performance.

Control

Unify robotics and automation with the Robotics Integrated Controller for flexible scaling and precise control.

Vision

OMRON’s IPC Application Controller supports 8 cameras for high-speed, precise image processing.

Safety

Safety sensors ensure human-machine collaboration, while Remote I/O cuts downtime and costs with reliable, real-time performance.

RELATED PRODUCTS

Adaptive processing for maximum output

Enhance safety and throughput with robotics automation tailored to your processing lines. Achieve consistent quality and operational excellence, freeing your team to focus on innovation.

Viper

6-axis robot for machine tending, fitting, and fastening—up to 5 kg.

OMRON TM S Series

Advanced collaborative robots for flexible tending, assembly, and welding.

i4L

Compact SCARA robots for fast pick & place, sorting, and assembly—up to 5 kg.

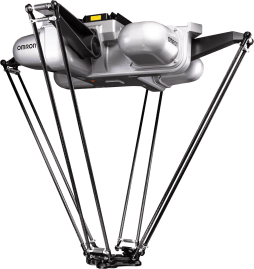

iX3 & Hornet

Parallel robots for high-speed sorting and packaging—up to 8 kg.

i4H

High-speed SCARA robots with ±0.015 mm precision and seamless integration—up to 15 kg.

iX4 & Quattro

Four-arm robot for multi-picking in sanitary, high-demand environments—up to 15 kg.

OMRON TM Series

Versatile cobots for tending, assembly, and palletizing.

Autonomous mobile robots

Autonomous mobile robots for lineside material transfer and replenishment.

Mobile Manipulators

Mobile manipulators for flexible picking and machine tending.

Industrial Part Feeders

Present and sort mixed parts for automated picking and continuous flow.