Automotive Manufacturing

Elevate safety, efficiency, and ROI with advanced automotive manufacturing solutions.

Accelerating output for every model, every shift

OMRON Robotics helps automotive and EV manufacturers tackle labor gaps, rising quality demands, and cost pressures with smart, scalable automation. Our robots take on high-risk, repetitive jobs—like material movement, assembly, and inspection—minimizing injuries and mistakes while ensuring safer, more consistent production at every stage.

Autonomous material transport

Eliminate production slowdowns and manual handling injuries by automating lineside parts delivery, heavy engine movement, and chassis transfers. OMRON LD series AMRs navigate crowded, narrow aisles for just-in-time delivery of components up to 250 kg. For larger loads, MD and HD models move pallets and assemblies up to 1500 kg. The OL-450S specializes in roll cage transport (450 kg). Manage up to 100 AMRs in real time with FLOW Core software to maintain steady line supply, reduce downtime, and maximize your investment.

High-speed automotive assembly

Meet tight cycle times and quality targets with robotic automation built for automotive assembly. Viper robots assemble gearboxes and dashboards with speed and accuracy, while SCARA robots handle polishing, dispensing, and intricate part placement. Collaborative robots enable safe, flexible screwdriving and light assembly right beside human workers, supporting quick changeovers and adaptable line layouts. Achieve consistent, high-quality builds and minimize rework.

End-to-end material flow

Optimize packaging, kitting, and palletizing of automotive parts with precise sorting, packing, and stacking into boxes, trays, and pallets. Viper robots manage heavy loads and ensure reliable material handling, while TM S series cobots work alongside operators for flexible, accurate packaging. Integrated AMRs enable adaptive, fully automated material flow from assembly through inspection to shipment.

Quality inspection & measurement

Meet stringent automotive quality standards and reduce defects with automated inspection. OMRON’s collaborative and 6-axis Viper robots perform repeatable, non-contact checks on welds, fasteners, and electronics—catching defects early, verifying dimensions, and ensuring compliance for every part leaving the line.

Automated welding, painting & spraying

Streamline your body shop and finishing lines by automating welding, painting, and spraying. OMRON cobots handle MIG, TIG, and CMT welding, as well as precision coatings, with consistent quality and minimal rework. Easy, no-code programming and built-in safety features allow fast deployment and safe operation in high-mix environments, while compact footprints fit into existing cells.

Next-generation material handling

Respond to changing production demands with Mobile Manipulator (MoMa) solutions, combining mobile and collaborative robots for flexible picking, placing, and transport. MoMas automate complex handling tasks, freeing operators for higher-value work and enabling rapid adaptation to new models or line changes.

Start optimizing your production today

Have questions? Let’s chat.

Smarter control, reliable outcomes

Benefit from OMRON’s complete automation solutions—integrate robots, PLCs, vision, and safety systems to accelerate automotive production, ensure traceability, and maintain seamless operations.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

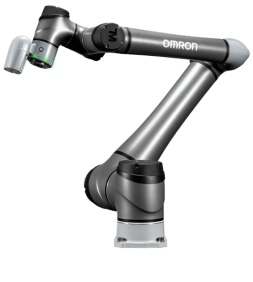

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable your automated systems to interact with their physical environment for precise performance.

Safety

Safety sensors promote harmony between humans and machines, with Remote I/O cutting costs and downtime, ensuring reliable networks.

RELATED PRODUCTS

Robotics solutions for automotive excellence

Apply proven automation solutions to overcome production bottlenecks, elevate quality, and create safer, more resilient operations.

Industrial robots

Boost line speed and cut defects in automotive assembly and inspection with high-precision, high-throughput industrial robots.

Autonomous mobile robots

Automate part and material transport to enhance safety and ensure continuous supply to your production lines.

Collaborative robots

Deploy collaborative robots to safely assist with repetitive assembly, testing, and palletizing alongside your team.

Mobile Manipulators

Enhance quality control with MoMas by automating inspections to rapidly detect weld cracks, paint defects, and assembly errors.