Back to case studies

How MPA Technology’s AMR Automation Handles 200 Crates Daily Across 5000m²

From manual crate transport to seamless, integrated automation

Before AMR automation, employees at a leading precision engineering company spent hours each day transporting small load carriers (KLTs) by hand—sometimes walking up to 15 kilometers and making 50 trips per shift just to move crates between storage and production. This manual process slowed down throughput, increased the risk of handling errors, and put unnecessary physical strain on staff.

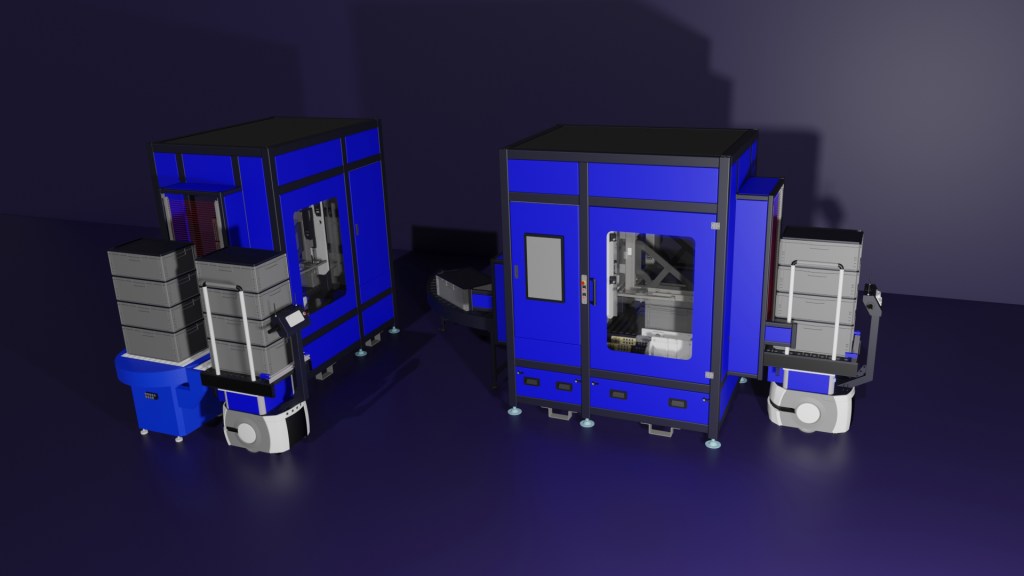

To address these challenges, MPA Technology GmbH designed a fully integrated system featuring OMRON LD-90 Autonomous Mobile Robots, Kardex automated shelving, and custom stacking units. Now, employees simply order materials from their workstations, triggering the Kardex to dispense KLTs to a stacker that organizes up to four crates at once. The AMRs then pick up and deliver these stacks with precise positioning, ensuring safe handling of delicate parts. Finished goods are returned to storage using the same automated process, with a destacker separating crates for easy reintegration. The whole system is connected to MES and SAP for real-time order management and traceability, streamlining both material flow and information flow across the facility.

With the new system in place, employees are freed from repetitive transport duties and can focus on higher-value tasks, while material flow is faster, more reliable, and less prone to error. With this scalable, integrated AMR automation approach, the facility is ready to meet future production demands with confidence.

Watch MPA Technology’s story:

Download in: Italian | German | Spanish | French | Polish

“With AMR automation, we’ve eliminated hundreds of manual crate transports each day. Our employees are now focused on value-adding tasks, and our material flow is faster, safer, and fully traceable.” — Nico Graneist, Key Account Manager, MPA Technology GmbH

Results at a glance:

- 200+ crates transported automatically every day

- Five LD-90 AMRs cover 5000m²

- 50 trips per robot per day—eliminating up to 15 km of manual walking daily

- Manual crate handling eliminated, reducing physical strain for employees

- Custom stacker/destacker enables safe transport of up to four KLTs at once

- System easily scalable to support future production growth

Tailored automation for precision engineering

By automating material transport and order processing, your team can spend less time on repetitive tasks and more time on skilled, value-added work. OMRON’s flexible, scalable systems adapt as your production grows—helping you improve efficiency, reduce manual strain, and keep operations running smoothly. If you’re considering how to modernize your material flow, let’s start the conversation about what’s possible in your facility today.

Related insights

See all insights