Back to case studies

15% Production Increase at Topcustom Through Cobot-Enabled Precision Sink Finishing

Transitioning from manual glue removal to a CAD/CAM-driven collaborative milling cell

Topcustom, an Italian manufacturer of custom Ocritech bathroom sinks, faced a persistent constraint at the finishing stage where operators manually removed 1.5–3 mm acrylic glue bands and deburred varied contours across a wide mix of geometries. This labor‑intensive approach introduced variability risk, consumed skilled time, and stretched order‑to‑delivery cycles toward three weeks when product mix peaked.

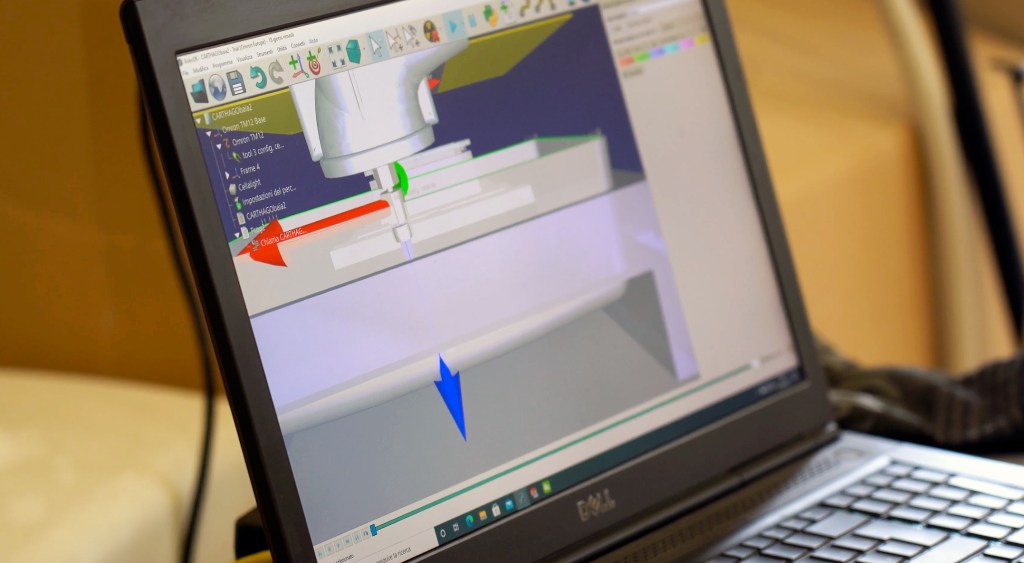

To overcome that constraint, an OMRON TM12 collaborative robot with 1300 mm reach was deployed to service both sides of a large fixture area without repositioning. Each sink program starts with CAD/CAM import of the customer’s 3D model, generating an initial path that is lightly adjusted once for tolerance compensation and then retained for repeat runs. The cobot performs precise glue residue removal and edge refinement while safety scanners allow supervised operation by pausing motion when personnel enter the zone. This converted finishing from a manual variability point into a stable data linked cell and a foundational layer of automated finishing supporting future production analytics.

As a result, output rose 15% to more than 800 sinks per week with a consistent two‑week order‑to‑delivery window. Rework from over‑trimming or incomplete cleanup declined, operators shifted from repetitive scraping to supervising multiple jobs, and engineering time moved from recreating edge sequences to onboarding new variants. Furthermore, linking product codes to validated toolpaths has prepared the operation for scalable digital scheduling and traceability—ensuring that reliable automated finishing now underpins faster response to custom requests without compromising surface quality or hygiene standards, and positioning the business for the next phase of optimization.

Watch Topcustom’s story:

Download in: Italian | German | Spanish | French | Polish | Turkish

Results at a glance:

- 15% increase in finished sink throughput now over 800 units per week

- Order to delivery window reduced to two weeks from a prior three week upper bound

- Consistent removal of 1.5–3 mm acrylic glue band with repeatable edge quality

- Dual side coverage from a single TM12 reach eliminates repositioning delay

- Product code to path linkage enables scalable digital traceability

- Labor redeployed from manual edge work to supervision and variant integration

- Safety scanner integration protects personnel without cycle penalty

Tailored automation for precision finishing

OMRON collaborated closely with the Topcustom team to shape a cell aligned to their high mix geometry set and hygiene driven surface criteria. By uniting collaborative robots, integrated safety, and CAD CAM data flow, the finishing phase now runs with predictable quality while freeing skilled staff for higher value tasks. If you are exploring how to remove a manual bottleneck or accelerate a custom production workflow with a focused automation solution, we are ready to engage and help design the path forward—let’s start the conversation.

Related insights

See all insights