Back to case studies

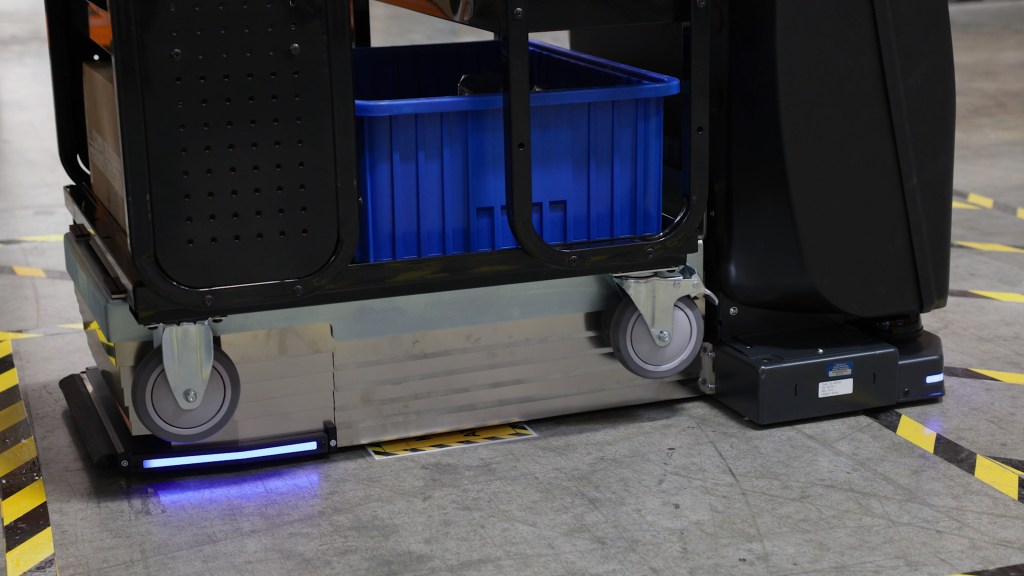

OL-450S AMR Increases Facility Output by 30% with Automated Roll Cage Handling

Solving high-mix, low-volume manufacturing challenges with adaptable intralogistics automation

At its Pleasanton, CA facility, OMRON Robotics manufactures a wide range of robots and safety devices, requiring frequent movement of parts between storage, assembly lines, and workstations. Previously, this material transport was handled manually, resulting in workflow bottlenecks, inconsistent delivery times, and skilled technicians spending hours each week on repetitive cart transfers.

To solve this, OMRON deployed the OL-450S Autonomous Mobile Robot into its operations. The OL-450S was quickly mapped to the facility’s existing layout, requiring no changes to aisles or workstations. Its omni-directional drive system made it possible to maneuver in tight spaces and adapt to last-minute route adjustments. Using FLOW Core software, team members now dispatch transport tasks directly from their tablets, and the robot automatically identifies and lifts various cart types—no manual intervention needed.

Within weeks, the impact was clear. Material deliveries became consistent and predictable, with the OL-450S completing hundreds of transfers per month across multiple shifts. The robot’s advanced safety sensors allowed it to operate smoothly alongside people and equipment, while wireless charging kept it running throughout the day. Most importantly, technicians were able to reclaim over 20 hours each week for assembly and testing, boosting output by 30% without adding headcount.

Watch OMRON’s story:

“The OL-450S has been a game-changer for us. It has not only improved our workflow but also allowed our team to focus on more strategic tasks. We couldn’t be happier with the results.” — Jun Barredo, Production & Factory Quality Manager

Results at a glance:

- 30% increase in material handling productivity

- 20+ technician hours per week freed for core manufacturing tasks

- 100% automated cart transfers between warehouse and assembly lines

- No facility layout changes required for robot navigation

- Safer, more efficient workflows for every shift

Tailored solutions for your intralogistics challenges

OMRON’s expertise in intralogistics automation empowers manufacturers to overcome material handling bottlenecks and unlock new levels of operational excellence. If you’re ready to streamline your processes or have questions about AMR integration, we’re here to help—let’s start the conversation.