Back to news

OMRON Announces Significant Expansion and Upgrade to Collaborative Robot Lineup and Software

Elevating automation with next-generation robotics and smarter software

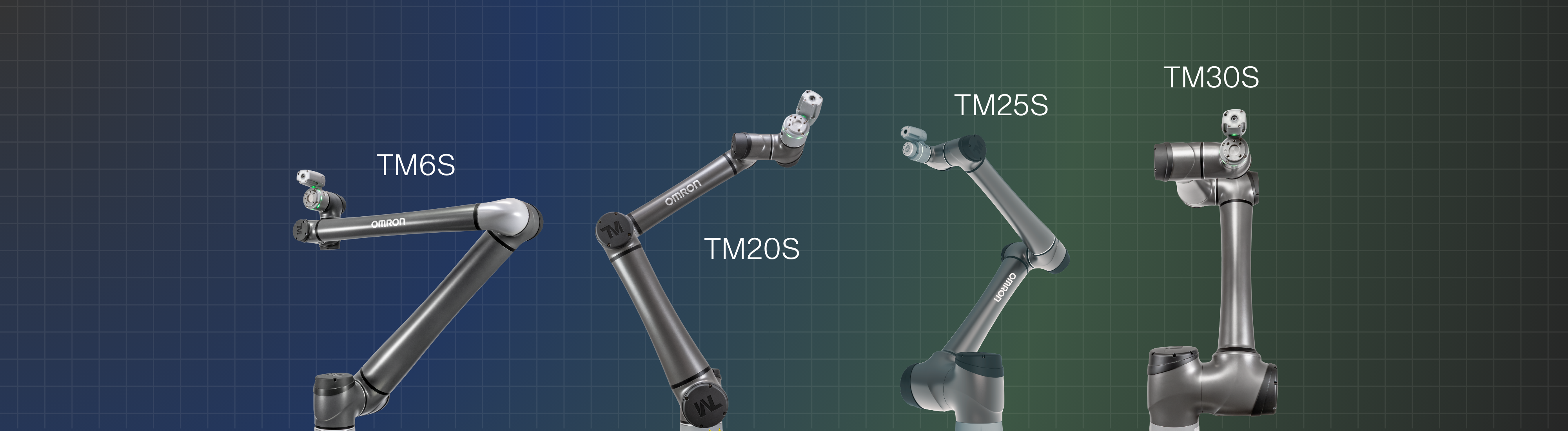

Pleasanton, California — December 12, 2025 — OMRON Robotics and Safety Technologies has announced a major expansion and upgrade to its TM S Series of collaborative robots. This comprehensive release introduces three new high-performance robots—the TM30S, TM20S, and TM6S—alongside critical hardware enhancements and the launch of the powerful TMflow 2.22 software platform.

These upgrades underscore our commitment to delivering flexible, safe, and intelligent automation solutions that directly address the growing demand for high-mix, low-volume production and critical labor shortages across global manufacturing sectors.

Next generation power and payload

The expansion of the OMRON TM S Series significantly broadens the range of demanding tasks that can be automated collaboratively:

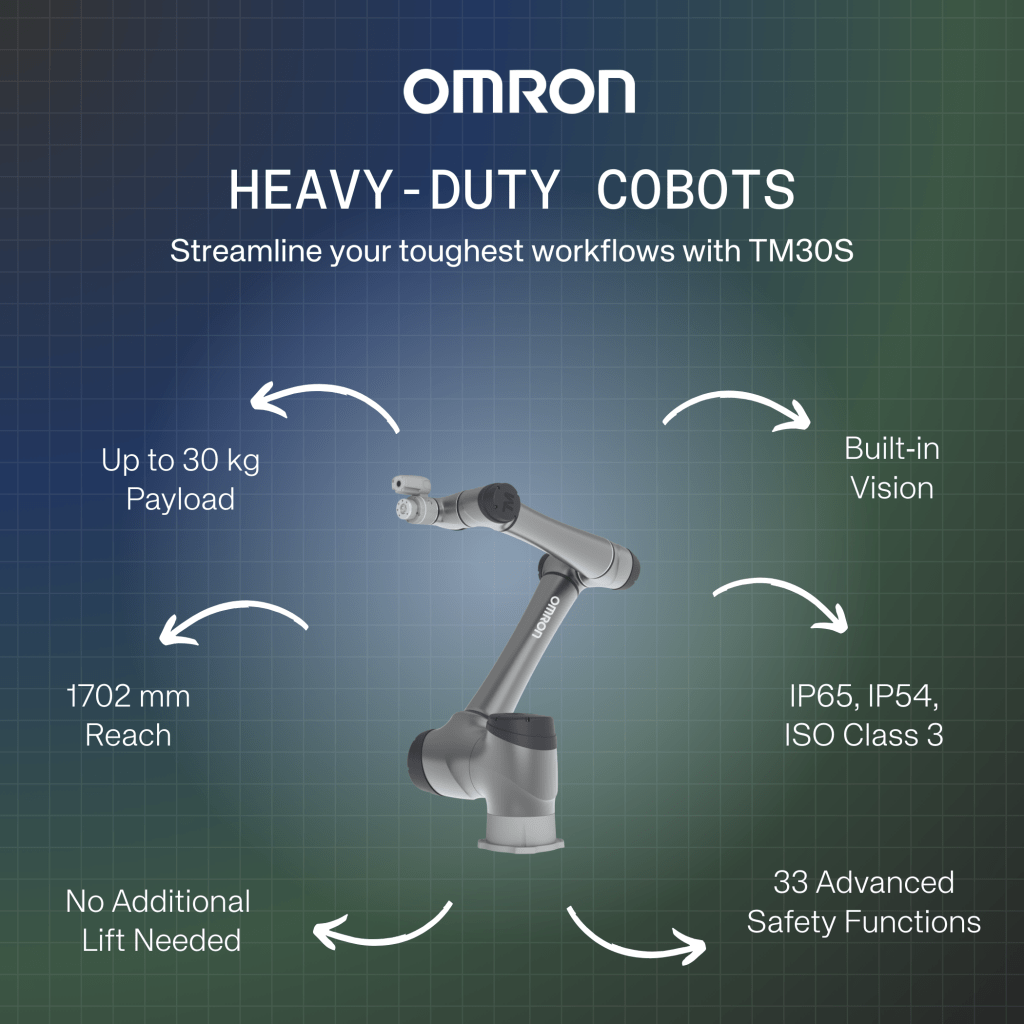

- TM30S (30 kg Payload): Designed for heavy-duty applications such as palletizing, machine tending, and mobile manipulators (MoMa), the TM30S offers industry-leading reach and power, pushing the boundaries of collaborative automation

- TM20S (20 kg Payload): Offering a perfect balance of reach and payload, this model is ideal for automating quality inspection, palletizing, and machine tending, driving significant productivity gains in mid-to-high payload operations.

- TM6S (6 kg Payload): This long reach, compact model is optimized for precision material handling, welding, and mobile manipulators, providing rapid and agile performance in large workspaces.

Explore all OMRON TM S Series robots here—find the right cobot for your application.

Hardware innovations for reliability and precision

The entire S Series line receives key hardware updates focused on making the robots more robust, precise, and adaptable for diverse industrial settings:

- IP65 Rating for All Arms: The robot arms are now certified with an IP65 rating, guaranteeing protection against dust ingress and low-pressure water jets. This makes the robots suitable for demanding environments requiring washdown, such as food and beverage processing, pharmaceuticals, and other clean-critical industrial settings.

- Integrated Joint 6 Force Torque Sensor for the heavy payload unit (TM25S and TM30S): A high-resolution Force Torque Sensor is now integrated into the wrist of the robots. This enables superior control for complex applications requiring highly responsive interaction, such as precise insertion, polishing, and delicate material handling, significantly improving process quality and consistency.

- Landmark 2.0 Positioning: The updated vision-based Landmark 2.0 technology offers even faster and more accurate robot orientation. This feature dramatically simplifies robot relocation, allowing manufacturers to move the robot to a new workstation and redeploy it immediately without time-consuming manual recalibration, maximizing uptime and flexibility.

“With the launch of the TM6S, TM20S, TM25S, and TM30S—plus major hardware upgrades like IP65 protection across the entire S Series, including the TM5S, TM7S, TM12S, and TM14S—and an integrated joint‑6 force torque sensor on the TM25S and TM30S, we’re enabling customers to tackle their toughest jobs with more safety, precision, and flexibility than ever.” — Qiqi Wang, Global Product Manager

Intelligence upgraded: Introducing TMflow 2.22

The new TMflow 2.22 software update enhances the platform’s intuitive user experience while integrating powerful new functionalities:

- Advanced Safety Improvements: TMflow 2.22 introduces more granular safety configurations, allowing for precise definition of collaborative-safe zones, speed limits, and stop behaviors, ensuring safer human-robot interaction.

- Expanded Remote Control Improvements: The update provides enhanced tools for remote monitoring and operation, enabling engineers to program, jog, and troubleshoot robots from a distance, minimizing downtime and improving support efficiency.

- Simulation and Advanced Improvements: The software now features an upgraded, high-fidelity simulation engine that allows for accurate offline validation of complex force-torque and motion workflows. Complementing this, the built-in vision system is expanded with more robust pattern matching, code reading, and color identification tools, simplifying inspection and pick-and-place tasks for faster, pre-validated deployment.

Find out how TMflow 2.22 can elevate your automation—see all updates.

About OMRON Robotics and Safety Technologies

OMRON Robotics is a global leader and key division of OMRON Corporation, dedicated to pioneering the next generation of industrial automation through advanced robotics solutions. With over 40 years of expertise and more than 46,000 robots deployed worldwide, OMRON provides a comprehensive portfolio structured around the philosophy: “To the machine, the work of the machine. To man, the thrill of further creation.”

Our product lines include Autonomous Mobile Robots (AMRs) for dynamic material logistics, Collaborative Robots for safe human-robot teamwork, and high-speed Fixed Industrial Robots (SCARA, Delta, and Articulated arms) for precision assembly and sorting. OMRON Robotics empowers manufacturers to build flexible, high-quality, and agile production lines by delivering solutions engineered to coordinate seamlessly and meet evolving market demands.

Related insights

See all insights