Digital Manufacturing

Boost safety and efficiency with our robotic solutions for digital manufacturing—delivering flexibility and rapid ROI.

Smart automation for connected manufacturing

From precise assembly and agile material movement to rigorous inspections, OMRON’s robots empower digital manufacturing in electronics, semiconductors, and advanced tech sectors. Adaptive systems and intelligent software drive higher throughput, lower costs, and support smarter, more sustainable production.

Efficient material handling

Automate contamination-free transport of wafers, components, and heavy loads with OMRON’s Autonomous Mobile Robots (AMRs). The LD series (ISO 5/Class 100) moves up to 250 kg for electronics and semiconductor processes. For higher payloads, the MD series (ISO 4/Class 10) handles up to 900 kg, while the HD series (ISO 5/Class 100) transports up to 1500 kg—perfect for microelectronics assembly and cleanroom logistics.

Safe, ESD-protected transport

Safeguard static-sensitive electronics with LD series AMRs featuring optional ESD protection. Certified to IEC 61340-5-1, these robots prevent electrostatic discharge with field strength protection above 40 kV/cm—ensuring safe, reliable material transport in electronics manufacturing.

Precision cleanroom-graded industrial robots

Meet strict contamination control requirements in semiconductor and biotech manufacturing with OMRON’s cleanroom-certified robots: Viper 6-axis articulated robots, and i4H and eCobra SCARA robots. Certified to ISO 4/Class 10, these robots minimize particle generation and ensure reliable, repeatable operation for high-yield manufacturing, sensitive material transfer, and ultra-clean automation in regulated cleanroom environments.

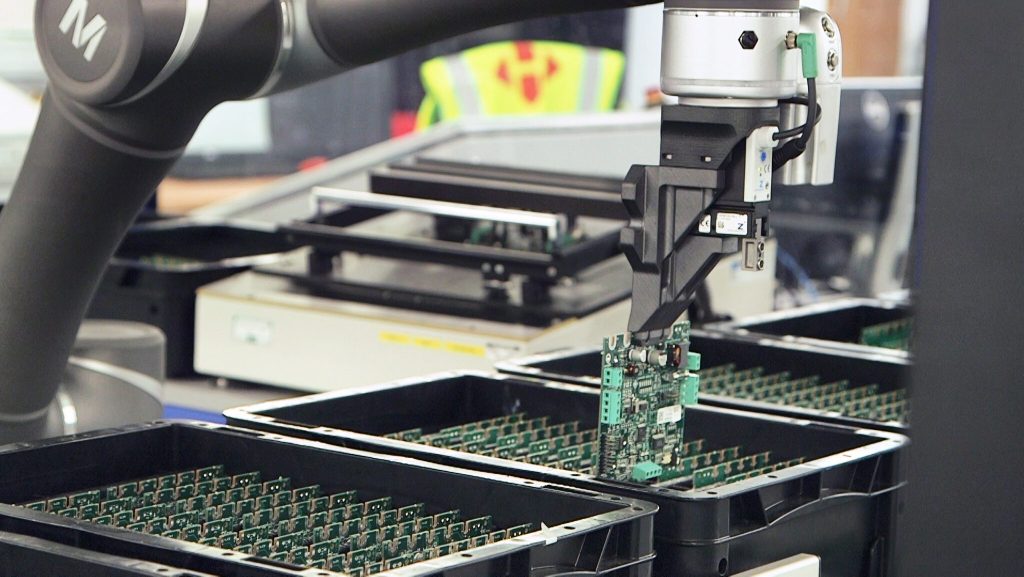

Flexible assembly & material handling

OMRON collaborative robots automate screwdriving, assembly, testing, PCB packaging, and material handling with cleanroom-certified speed and precision. TM S Series cobots meet ISO Cleanroom Class 3 and SEMI S2 standards, offering solutions for high-mix, low-volume production and delicate component handling. Integrate easily to improve yield, maintain quality, and accelerate production cycles.

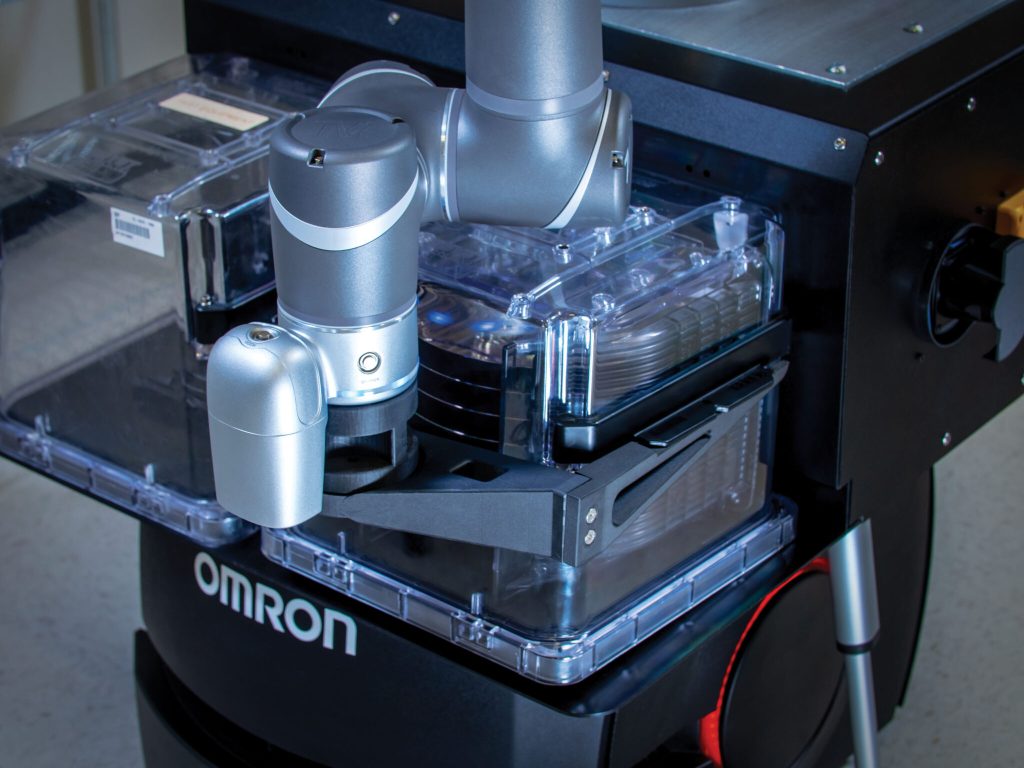

Next-generation material handling

Combine TM S Series cobots (ISO Cleanroom Class 3, SEMI S2) with LD series AMRs (ISO 5/Class 100) for advanced Mobile Manipulator solutions. MoMas automate picking, placing, and transport of sensitive materials, enabling precise, efficient workflows in cleanroom environments and supporting scalable, future-ready manufacturing.

Start optimizing your workflows today

Have questions? Let’s chat!

Smarter control, seamless production

Streamline production with Omron’s automation solutions. Connect robots, vision systems, safety devices, HMIs, and PLCs on one platform for unified control. Intuitive tools and simulation enable faster deployment and easier troubleshooting.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable automated systems to interact with their physical environment, ensuring precise performance.

Safety

Safety sensors promote harmony between humans and machines, with Remote I/O cutting costs and downtime, ensuring reliable networks.

RELATED PRODUCTS

Advanced solutions for modern manufacturing

Maximize productivity and uptime with advanced robotic solutions for digital manufacturing. Achieve precise quality control and accelerate throughput at every stage of production.

Collaborative robots

Automate repetitive tasks safely with OMRON collaborative robots, reducing worker strain and boosting productivity.

Autonomous mobile robots

Speed up material flow and adapt to changing demands with AMRs, cutting downtime and manual handling.

Industrial robots

Increase assembly speed and product quality with industrial robots, ensuring consistent, precise operations.

Mobile Manipulators

Automate inspections and adjustments with MoMas, combining mobility and precision for greater production flexibility.

Related insights

Get more insights

Automated Machine Tending Increases Capacity and Efficiency at Laser Quality Markings

How MPA Technology’s AMR Automation Handles 200 Crates Daily Across 5000m²

Inside Normagrup’s Shift to Automated Handling Using AMRs with Custom Conveyors