Medical Manufacturing

Improve safety and efficiency with medical manufacturing robots, providing flexibility and fast ROI.

Assurance for every device, any regulations

Stay ahead of regulatory requirements and market shifts with OMRON’s medical manufacturing robots. Our solutions automate key processes, lower contamination risk, and deliver traceable quality, supporting compliance and efficiency for manufacturers in a rapidly evolving sector.

Safe, precise medical assembly

Automate medical device and pharmaceutical assembly, packaging, and palletizing with OMRON TM S Series collaborative robots—certified for ISO Cleanroom Class 3 and SEMI S2 standards. Select the TM5S or TM7S models for compact screwdriving, intricate assembly, and testing in sterile environments, while the TM12S and TM14S offer higher payloads for demanding material handling and assembly tasks. For efficient palletizing, the TM25S handles larger loads up to 25kg with ease. These advanced cobots help you reduce contamination risks, boost product quality, and streamline compliance with industry regulations.

High-speed pick-and-place and packaging

Achieve ultra-clean, high-throughput automation with articulated, SCARA, and parallel robots engineered for ISO 4/Class 10 cleanrooms and multiple IP protection levels. Streamline blister packing, syringe assembly, pipetting, and palletizing operations while minimizing human contact and contamination. These solutions deliver reliable performance and help meet the most stringent industry standards for medical and pharmaceutical manufacturing.

Automated material handling

Safely and efficiently move raw materials, finished goods, and biohazard waste between cleanrooms, labs, and production areas with Autonomous Mobile Robots (AMRs). LD and HD series (ISO 5/Class 100) and MD series (ISO 4/Class 10) deliver full traceability, reduce manual handling and cross-contamination, and meet strict cleanroom standards. Customize AMRs with toppers, conveyors, racks, or carts to automate material delivery, waste removal, and component transfer. Easily integrate AMRs into your workflow to streamline logistics, respond quickly to production changes, and ensure contamination-free transport in medical manufacturing.

UV-C disinfection for healthcare

Protect patients and staff with autonomous UV-C robots that disinfect air and surfaces using UV-C light. Ideal for hospitals and healthcare centers, these robots ensure consistent, automated sterilization in patient rooms, operating theaters, and high-traffic zones—reducing infection risk and supporting rigorous hygiene standards.

Next-gen material handling

Unlock advanced, flexible automation for sensitive environments with MoMa applications—integrating OMRON’s LD or MD AMR base and TM S Series collaborative arm (ISO Cleanroom Class 3) into one solution. The AMR navigates cleanrooms while the robotic arm handles precise picking, placing, and transport, streamlining multi-step tasks and ensuring compliance for medical manufacturers.

Start optimizing your production today

Have questions? Let’s chat!

Automate your application

Maximize production efficiency with Omron’s automation solutions—program and sync robots, PLCs, vision systems, and safety devices on one platform. Integrated simulation accelerates deployment and troubleshooting for seamless, compliant operations.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable automated systems to interact with their physical environment, ensuring precise performance.

Safety

Safety sensors promote harmony between humans and machines, with Remote I/O cutting costs and downtime, ensuring reliable networks.

RELATED PRODUCTS

Robots for safer, traceable manufacturing

Streamline repetitive and hazardous tasks in sterile medical production with robotics that deliver consistent quality, full traceability, and reduced contamination risk.

Industrial robots

Ensure consistent, high-speed assembly and inspection to meet strict quality and regulatory demands.

Autonomous mobile robots

Automate material transport between cleanrooms and labs, reducing manual handling and contamination risks.

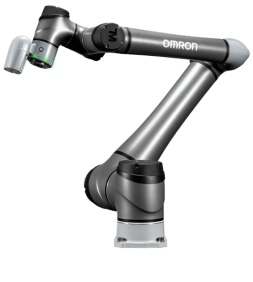

Collaborative robots

Safely automate repetitive tasks alongside staff, enhancing flexibility and maintaining sterile conditions.

Mobile Manipulators

Integrate Mobile Manipulators (MoMas) for complex inspection and handling in sensitive production areas.

Related insights

Get more insights