Logistics Automation

Maximize efficiency and streamline operations with OMRON’s flexible material handling robots.

Efficient flow for every order, every route

OMRON brings together mobile, collaborative, and industrial robots to keep your logistics moving. Whether it’s automated transport, precise picking, or reliable palletizing, our solutions help you streamline workflows, optimize supply chains, and keep productivity on track—no matter the challenge.

Automated transport for light tasks

OMRON’s LD series Autonomous Mobile Robots (AMRs) bring smart automation to your logistics from day one. With custom mapping and seamless integration, these robots streamline workflows and optimize supply chains—no renovations needed. The powerful FLOW Core software coordinates up to 100 AMRs for intelligent job assignment, smooth traffic flow, and efficient charging. Precise navigation and real-time connectivity with MES, ERP, and WMS systems help boost productivity and keep your operations flexible as demands change.

Effortless handling of large loads

Power heavy-duty logistics with OMRON’s MD and HD series AMRs. The MD moves up to 900 kg, fits global pallets, and features rapid charging for continuous operation. The HD handles loads up to 1500 kg for safe, efficient transport of palletized goods and other bulky items. Both models use dynamic 360° safety systems and optional 180° vertical scanners, instantly adapting over 70 safety zones for fast, protected movement in high-traffic environments. Fully compliant with ISO 3691-4 and ANSI/RIA R15.08, these AMRs set the benchmark for safe, efficient automation of large loads—maximizing throughput and minimizing manual handling.

Faster palletizing, fewer bottlenecks

OMRON’s TM S Series cobots optimize palletizing with tailored models for every payload. The TM7S stacks small parcels in space-constrained areas. TM12S and TM14S automate multi-tier pallet builds with heavier cartons, supporting rapid SKU changes in cross-docking and fulfillment centers. For bulk shipments, the TM25S automates stacking of boxes up to 25 kg, reducing manual lifting in outbound staging. Each cobot’s integrated vision system ensures precise stacking, even with mixed SKUs, while rapid redeployment supports fast product changeovers. This automation reduces mis-stacked pallets, shortens cycle times during high-volume periods, and lowers injury rates in busy distribution hubs.

Efficient roll cage transport

The OL-450S automates roll cage transport—handling both standard and custom load carriers with a versatile lift range from 108 to 308 mm. Its adaptable design integrates easily into any logistics workflow, no facility changes required. By reducing manual cart movement, the OL-450S increases scheduling precision and keeps material flowing smoothly, even in high-traffic or specialized environments.

Smart picking and sorting

Combine LD AMRs with TM S cobots for a new level of automation. Mounting an OMRON TM cobot onto an OMRON LD or MD mobile robot automates not only transportation of goods but also complex picking operations. MoMas streamline precise picking, sorting, and handling—cutting labor costs and minimizing errors. This flexible, integrated solution accelerates order fulfillment and delivers reliable, scalable supply chain performance for even the most dynamic operations.

Precise, high-speed picking & packing

OMRON’s iX3, Hornet and iX4, Quattro parallel robots deliver rapid, precise automation for logistics and manufacturing. With payloads up to 15 kg, reach up to 1300 mm, and cycle times as quick as 0.30 seconds, they excel in order fulfillment, parcel sorting, and packaging lines. Advanced EtherCAT connectivity and flexible programming enable seamless integration with existing systems. Hygienic models meet strict industry standards, ensuring reliable, error-free performance while reducing bottlenecks and manual labor.

Consistent accuracy in every task

The i4L and i4H SCARA robots deliver high-speed automation for tasks such as pick-and-place, kitting, sorting, and packaging. The compact i4L excels at light-duty tasks with fast cycle times, easy mounting, and interactive maintenance alerts that help reduce downtime. The robust i4H handles heavier payloads up to 15 kg, offers flexible mounting options, and features specialized models for food-grade and cleanroom environments. Both series integrate seamlessly with EtherCAT or Ethernet connectivity, enabling quick setup and reliable performance across manufacturing and logistics operations.

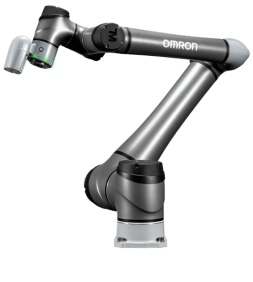

Flexible arms for complex handling

Viper 6-axis robots provide flexible, high-precision automation for material handling, palletizing, and machine tending. With 5 kg payloads, lightweight arms, and efficient drives, they offer fast, accurate, and repeatable performance. Reach options of 653 mm and 855 mm, high-resolution encoders, and easy calibration enable precise sorting and assembly. Industrial network connectivity ensures seamless integration with existing systems, while cleanroom and IP65 models suit specialized environments. Simple programming and deployment streamline workflows and boost throughput.

Start optimizing your workflows today

Have questions? Let’s chat!

Automate your applications

Maximize logistics productivity with Omron’s complete automation solutions—program and sync robots, vision systems, and safety devices to optimize order fulfillment, sorting, material handling, and warehouse processes for seamless operations.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable automated systems to interact with their physical environment, ensuring precise performance.

Safety

Safety sensors promote harmony between humans and machines, with Remote I/O cutting costs and downtime, ensuring reliable networks.

RELATED PRODUCTS

Consistency you can always count on

Discover our lineup of AMRs, cobots, and industrial robots—built to maximize throughput, reduce downtime, and deliver reliable performance.

Autonomous mobile robots

Automate transport of goods throughout warehouses and distribution centers, reducing labor and manual handling.

Collaborative robots

Enhance flexibility and safety in collaborative tasks, adapting quickly to changing logistics needs.

Industrial robots

Improve picking, packing, and palletizing speed and accuracy for streamlined logistics workflows.

Mobile Manipulators

Integrate mobile and collaborative robots for complex, multi-stage material handling and inspection.

Related insights

Get more insights

OL-450S AMR Increases Facility Output by 30% with Automated Roll Cage Handling

Collaborative Palletizer Handles Up to 8 Boxes per Minute, Accelerating ROI for Industrial Manufacturers

VOLA’s Made-to-Order Success with Nine OMRON LD Series AMRs