Back to case studies

Polar Semiconductor Cuts 40 Miles of Manual Material Transport with LD Series AMRs

Advancing productivity and workforce efficiency through automated logistics

Polar Semiconductor, a leading U.S. chip manufacturer serving the automotive and white goods industries, faced a significant challenge: internal material transport spanned over 40 miles throughout each product’s lifecycle. This manual, repetitive task not only slowed production but also diverted skilled employees away from critical operations—at a time when finding qualified workers is increasingly difficult.

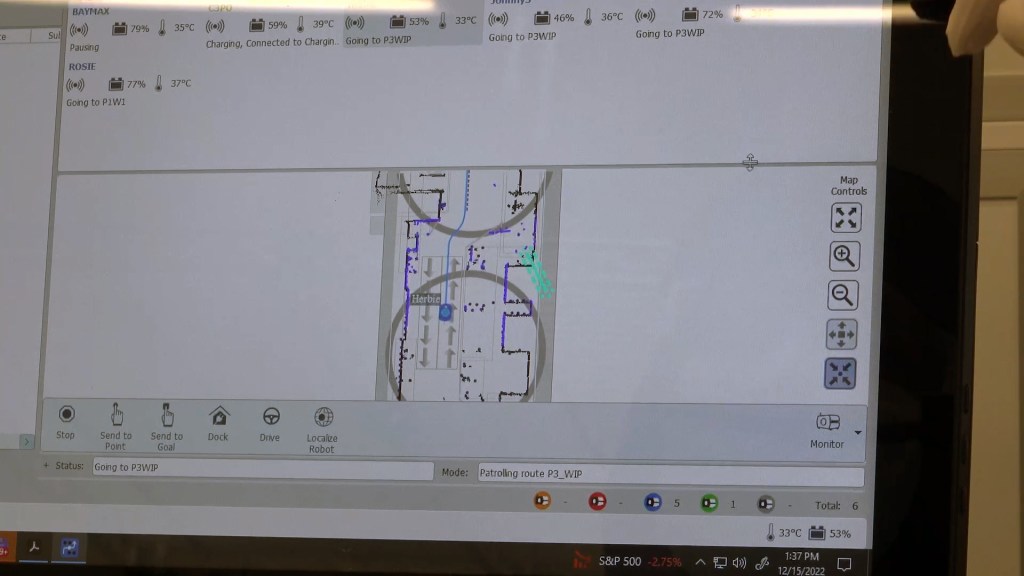

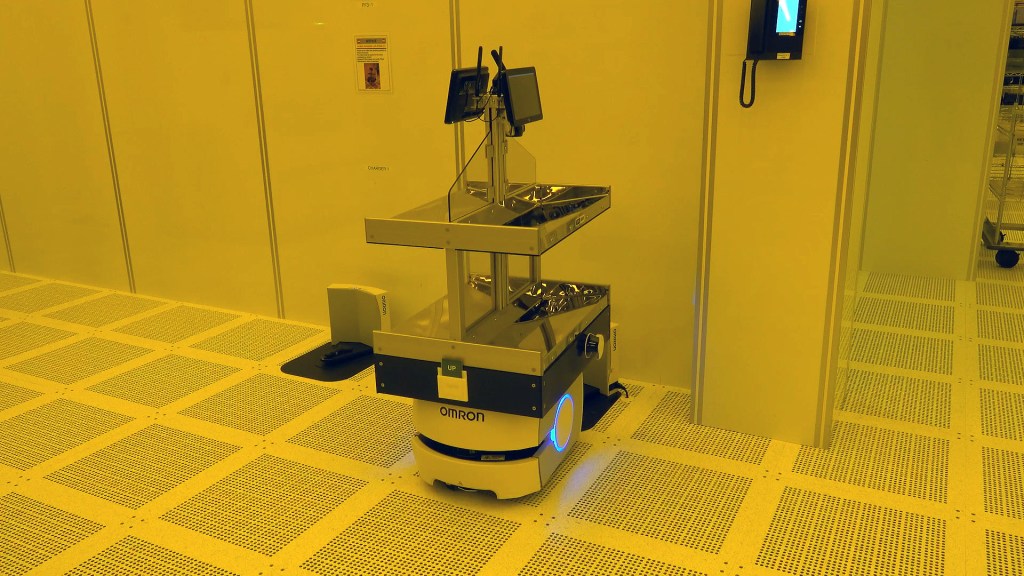

To address these inefficiencies and support their expansion, Polar Semiconductor partnered with OMRON to implement a flexible, cost-effective automated material handling solution. After a comprehensive mapping and simulation of their facility, Polar deployed a fleet of seven OMRON LD-60/90 Autonomous Mobile Robots (AMRs). These AMRs autonomously navigate complex and dynamic factory environments, efficiently transporting materials from central storage to production lines—freeing operators to focus on high-value tasks and keeping equipment running.

The results have been transformative. Automated material handling now ensures smooth, uninterrupted material flow, saving operators thousands of miles of walking each year and significantly improving productivity. Initial concerns about operator acceptance quickly gave way to enthusiasm, as employees embraced the robots’ ability to streamline their daily routines.

Watch Polar Semiconductor’s story:

“Having these robots available to move work-in-progress quicker, easier, without relying on operators to move from the equipment they’re working on. The biggest advantage I’ve seen is that we’ve been able to have the robots maneuver more like a person does.” — Darren Desmarais, Industrial Engineer, Polar Semiconductor

Results at a glance:

- Over 40 miles of internal material movement automated per product lifecycle

- Seven AMRs deployed for hands-free material transport

- Operators refocused on value-added work, boosting efficiency

- Enhanced workflow and productivity across the facility

Tailored solutions for your material transport needs

OMRON’s experience with automated material handling is helping manufacturers like Polar Semiconductor unlock new efficiencies and improve daily operations. If you’re exploring ways to streamline your own processes or have questions about robotics integration, we’re here to help—let’s start the conversation.

Related insights

See all insights