Food & Commodities

Boost safety and efficiency with our food and commodities robots, providing flexibility and fast ROI.

Meeting standards for every batch, every delivery

OMRON Robotics delivers tailored automation for food and commodity manufacturers, tackling hygiene compliance, labor shortages, and shifting demand. Our food-grade robots ensure safe, high-speed processing, precise sorting, smart packaging, and efficient palletizing—boosting throughput, ensuring quality, and meeting strict industry standards.

Automated food processing & handling

Ensure top hygiene and safety with food-grade parallel, SCARA, and collaborative robots—built for sanitary washdowns and contamination control. Quattro, iX4 and Hornet, iX3 parallel robots offer high-speed, precise handling for snacks, beverages, and bulk goods. i4H SCARA robots offer flexible, cleanroom-ready sorting and packaging, while TM S cobots work safely alongside staff for gentle handling, labeling, and stacking. Automation reduces product damage and recall risks, supporting consistent quality and reliable throughput for food and commodity lines.

End-of-line packaging & palletizing

Automate packing, sorting, labeling, and palletizing for products of any size—from snack packs to bulk goods. OMRON’s robotics streamline packaging lines, adapting quickly to changing SKUs and handling delicate items with speed and precision. Parallel robots excel at high-speed pick-and-place for fast throughput, collaborative robots ensure safe and gentle handling alongside human workers, SCARA robots sort and assemble small parts, and Viper robots offer precise, high-payload handling for complex palletizing—all supporting efficient, reliable packaging operations.

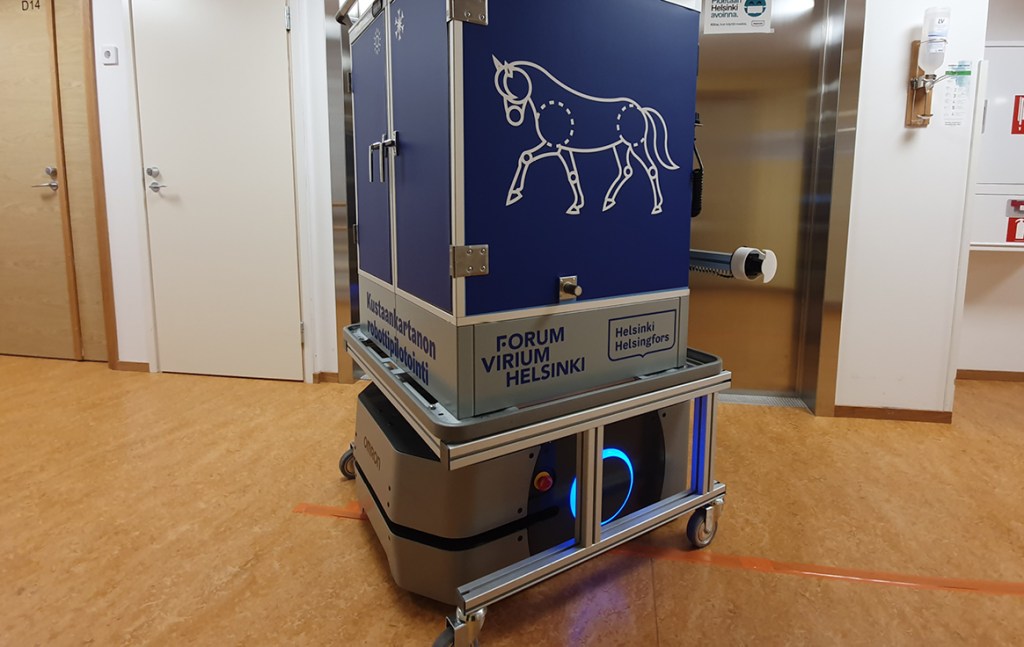

Autonomous material transport

Eliminate manual transport bottlenecks with Autonomous Mobile Robots (AMRs). AMRs move raw ingredients, packaging supplies, and finished goods between processing, storage, and shipping zones. This eliminates manual cart pushing, improves traceability, and keeps lines supplied without interruption, supporting lean inventory management.

Inspection & quality assurance

Automate inspection and quality control with collaborative robots. The OMRON TM S Series introduces new hardware options and 12 additional safety features—including enhanced emergency stops, joint monitoring, and external safeguard inputs—plus certifications like ISO 13849-1 (Cat.3, PL d) and IP54 protection for special environments. These cobots work safely alongside your team to inspect for defects, measure fill levels, and verify labeling accuracy, enabling real-time quality checks, reducing human error, streamlining compliance documentation, and protecting your brand reputation in food and commodity production.

Next-generation material handling

Meet the highest hygiene and safety standards with Mobile Manipulators (MoMas), combining a collaborative robotic arm and AMR for advanced automation in cleanroom and food-safe environments. MoMas automate tasks such as picking items from storage, replenishing production lines, and transferring samples for laboratory testing. Their flexibility supports frequent product changeovers and high-mix, low-volume production environments.

Start optimizing your production today

Have questions? Let’s chat!

Automate your application

Maximize production efficiency and meet food industry standards with Omron’s automation solutions—program and sync robots, PLCs, vision systems, and safety devices on one platform. Integrated simulation enables rapid deployment and troubleshooting, ensuring safe, and compliant operations.

Motion

Servos optimize your automated line, reducing downtime and maintenance, while Industrial PCs ensure precise process control.

Robotics

Industrial, mobile, and collaborative robots enhance productivity and easily adapt to a wide range of applications with precision.

Control

Control units maximize productivity and save space, while Programmable Logic Controllers offer full control over your processes.

Vision

OMRON cameras and vision sensors enable automated systems to interact with their physical environment, ensuring precise performance.

Safety

Safety sensors promote harmony between humans and machines, with Remote I/O cutting costs and downtime, ensuring reliable networks.

RELATED PRODUCTS

Robotics solutions for efficient production

Deploy automation that ensures hygienic processing, precise quality control, and efficient material handling—helping you meet safety regulations and market demands.

Industrial robots

Rapid, accurate food processing and inspection—reduce waste and ensure consistent quality.

Autonomous mobile robots

Automate material movement with AMRs, adapting to changing factory layouts and reducing manual transport risks.

Collaborative robots

Safe automation for repetitive tasks and delicate handling; support workforce safety and productivity.

Mobile Manipulators

Combine mobility and precision for automated picking, placing, and inspection in hygienic environments.

Related insights

Get more insights