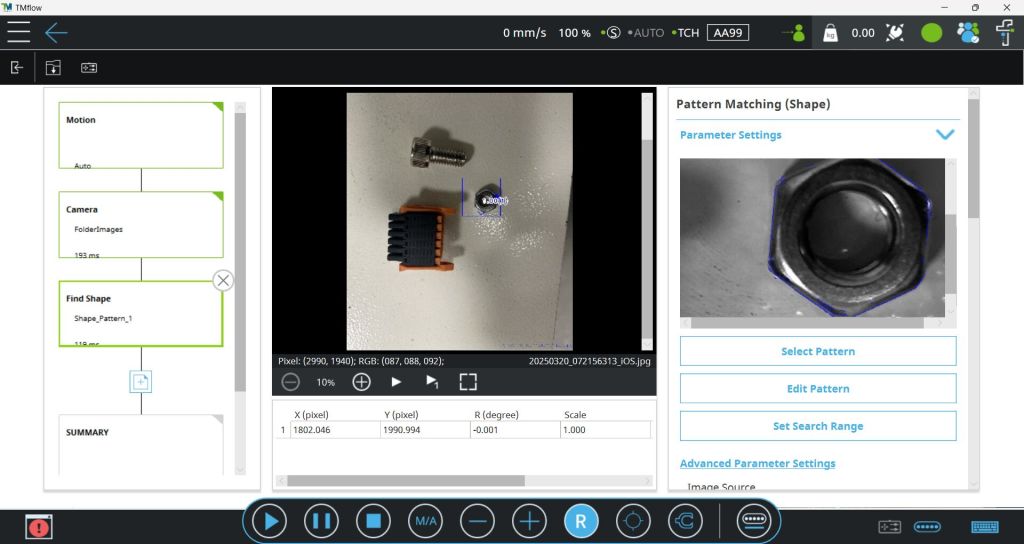

TMflow software

TMflow 2.22 makes programming collaborative robots faster, easier, and more flexible than ever.

now

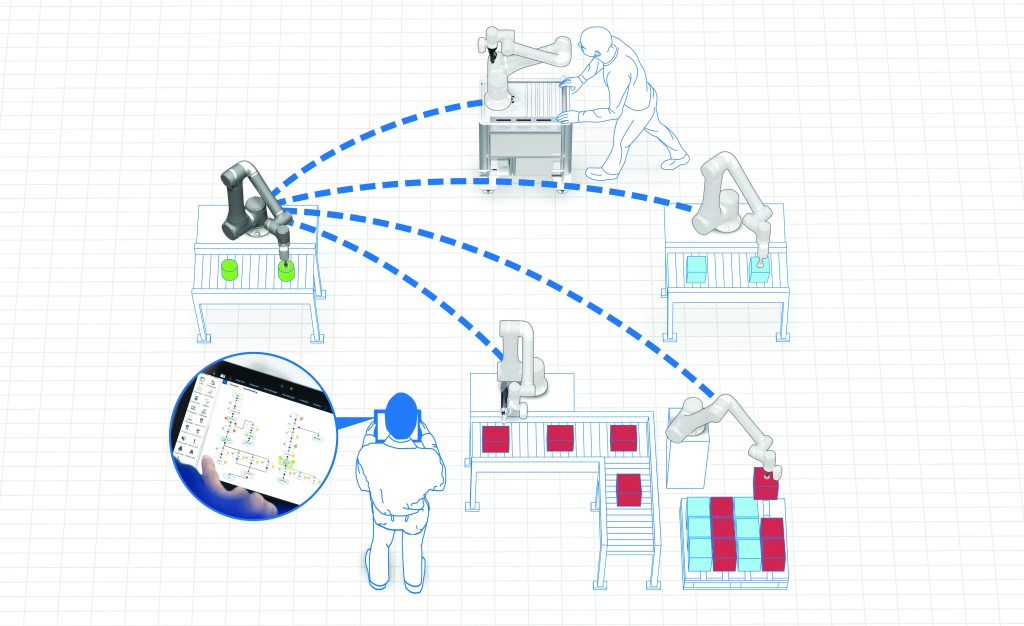

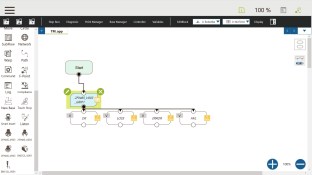

TMflow is OMRON’s intuitive software platform for collaborative robots, combining flow‑based programming, integrated vision, and advanced safety tools in a single environment. It lets you build applications step by step—from simple pick‑and‑place or screwing to vision inspection, deburring, and labelling. With offline simulation, landmark‑based repositioning, and scripting for advanced users, you can refine ideas without stopping production. TMflow puts the power of advanced automation directly in your hands.

Next‑generation programming for your cobots

TMSimulator for TM S Series

Develop, edit, and run programs in a virtual environment—testing motion, logic, and communication before deployment to avoid downtime and speed up commissioning.

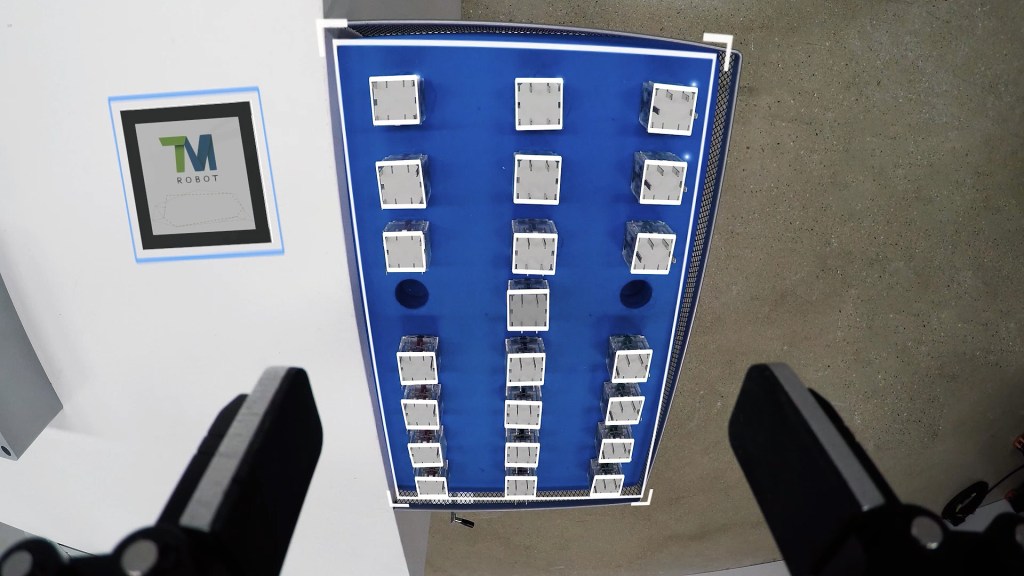

Landmark 2.0 navigation

Use physical Landmarks with integrated vision for position referencing, so robots can be moved and realigned quickly without complex recalibration in high‑mix environments.

Virtual robot stick

Mirror the physical Robot Stick on your PC, allowing operators to teach, jog, and manage robots remotely with familiar controls and less time at the cell.

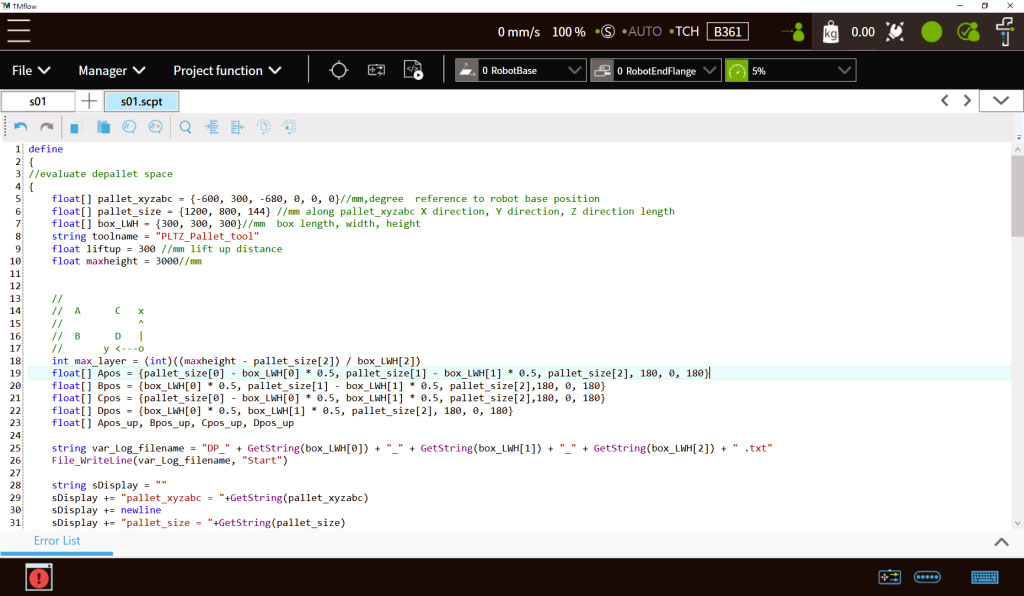

Script programming for advanced users

Combine TMflow’s graphical flows with TMScript for compact, powerful logic—giving power users finer control over motion, communication, and custom behaviors.

Save time and streamline your applications

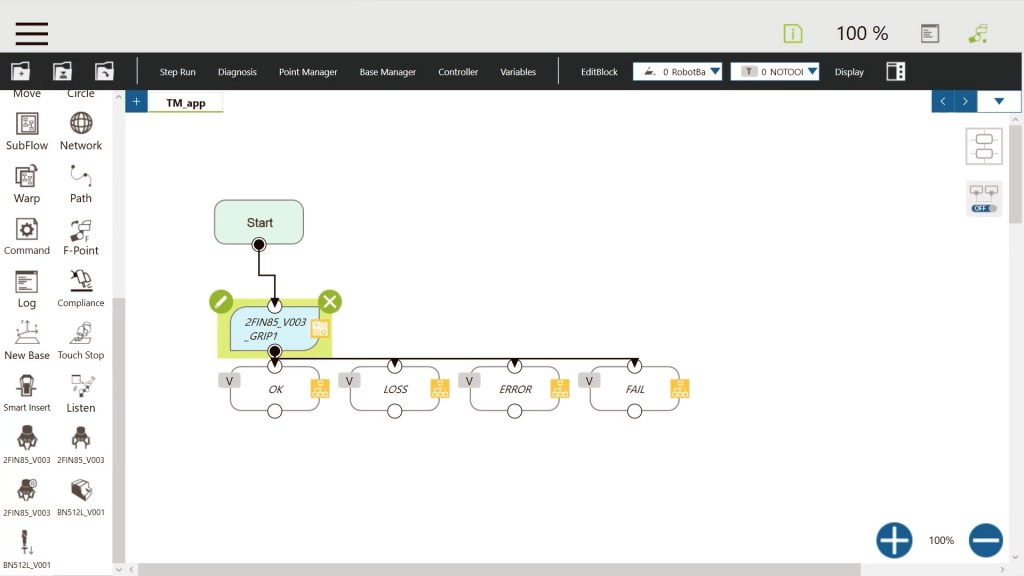

Build workflows faster

Flowchart‑based, drag‑and‑drop programming turns complex tasks into clear visual steps—cutting setup time and making it easier to adjust and redeploy applications as your needs change.

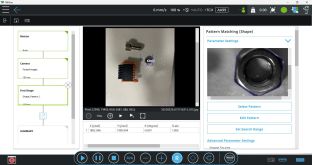

Precision vision, built in

Integrated, industrial‑grade vision handles pattern recognition, positioning, inspection, and measurement without extra hardware—ensuring accurate pick‑and‑place and labeling, even in high‑mix environments.

Maximize uptime with offline development

TMSimulator and improved error‑handling logic enable projects to be built, tested, and refined entirely offline—keeping robots in production while new workflows and recovery strategies are proven in advance.

Certified safe collaboration

Advanced safety tools work together with 33 certified safety functions—supporting ISO 13849‑1 Cat.3 PL d, ISO 10218‑1, and ISO/TS 15066 compliance, and making safe human‑robot collaboration simpler to configure and maintain.

Start automating your production today

Have questions? Let’s chat.

RELATED PRODUCTS

Certified collaboration that fits your flow

Unlock safe, high‑performance automation with the OMRON TM S Series—collaborative robots from 5 to 30 kg payloads, built to handle everything from precise handling to heavy‑duty applications on a single, scalable platform.

View brochure

TM5S

Ideal for light assembly and small‑part handling where space is tight and precision matters.

TM6S

Made for agile pick‑and‑place and quick changeovers on fast‑moving production lines.

TM7S

Excels at vision‑driven tasks like packaging, inspection, and labeling with high accuracy.

TM12S

Handles medium‑weight parts for handling, palletizing, and process work close to people.

TM14S

Carries heavier tools and fixtures for machining support, tending, and finishing jobs.

TM20S

Built for demanding handling, palletizing, and intralogistics with solid payload capacity.

TM25S

Takes on large, bulky parts and end‑of‑line tasks where higher loads are the norm.

TM30S

Delivers maximum lifting power for the toughest palletizing and material‑handling duties.

RESOURCES

TMflow software updates & documentation

Stay up to date with the latest software upgrades, free tools, and support files to enhance your cobots and optimize your systems.

Get the latest updates

Related insights

See all insights